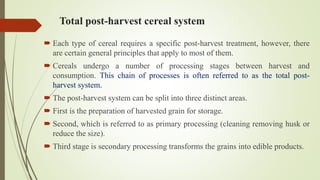

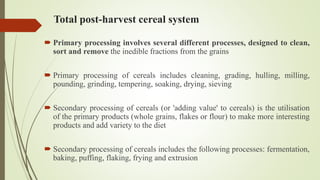

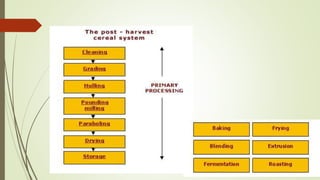

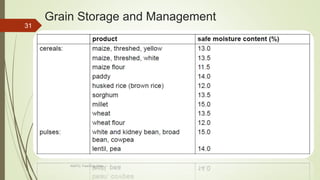

This document discusses the primary processing of cereals after harvest. It explains that cereals undergo cleaning, grading, hulling/milling, and drying before storage. The primary processing stages involve cleaning and sorting grains to remove inedible parts. Common primary processing techniques include cleaning, grading, hulling, milling, pounding, grinding, tempering, soaking and drying. Secondary processing then transforms the grains into finished food products using techniques like fermentation, baking, puffing and extrusion. The document provides details on specific primary processing steps like hulling/decortication, parboiling, drying and storage.