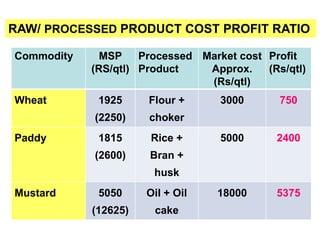

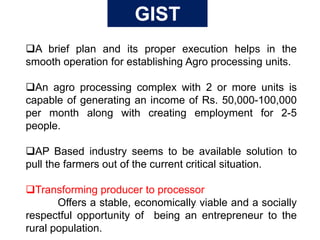

This document discusses the benefits and concepts of establishing agro-processing complexes (APCs) at the village level. Key points:

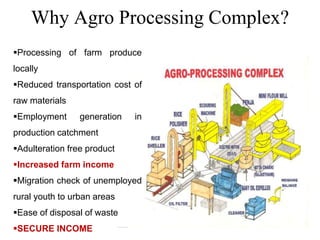

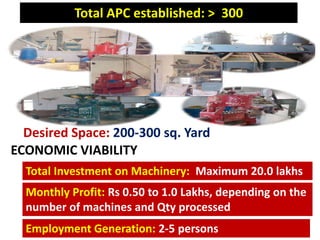

1. APCs allow for local processing of farm produce, reducing transportation costs and generating local employment. They also help control adulteration, increase farm incomes, and stem rural-to-urban migration.

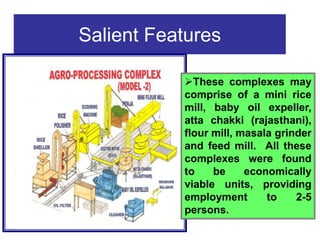

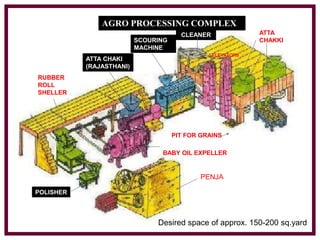

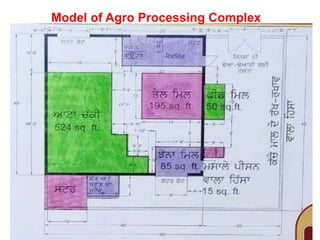

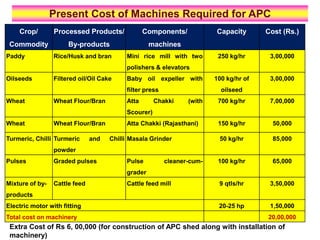

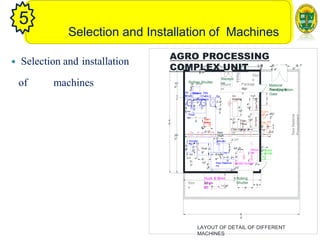

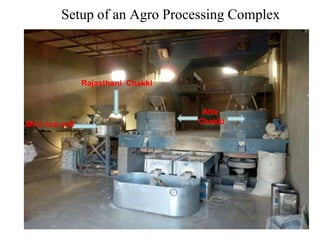

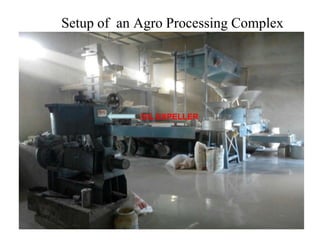

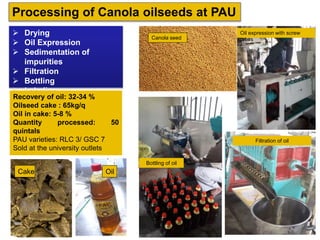

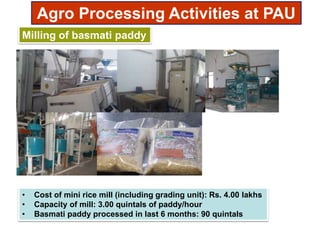

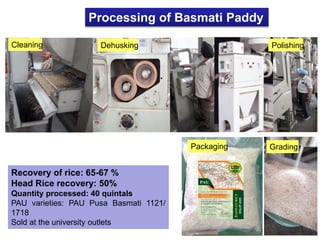

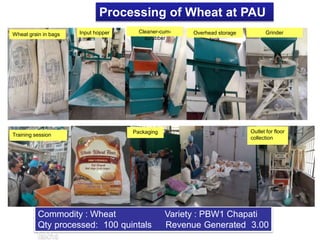

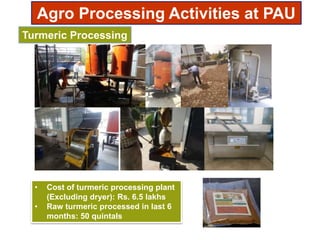

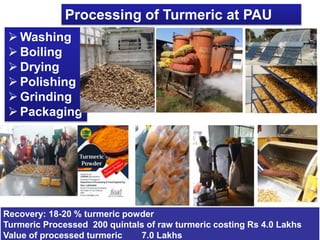

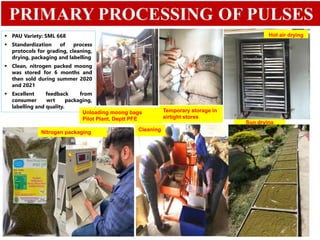

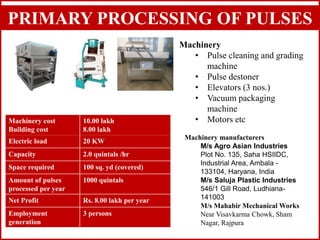

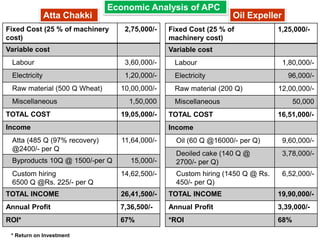

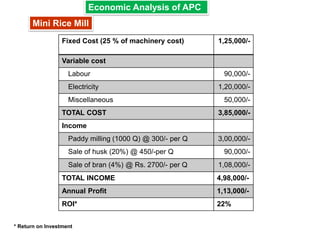

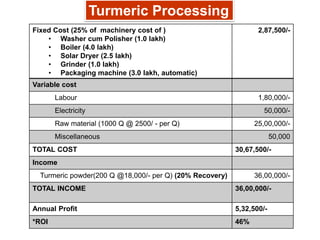

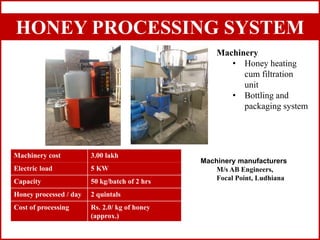

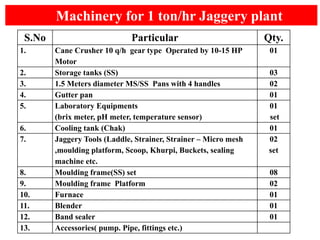

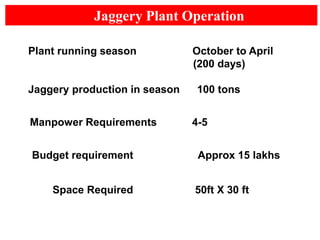

2. An APC is a facility housing multiple crop processing units like rice mills, oil expellers, flour mills, and spice grinders. Factors favoring APC development include raw material availability, economic gains, government policies/subsidies, and employment generation.

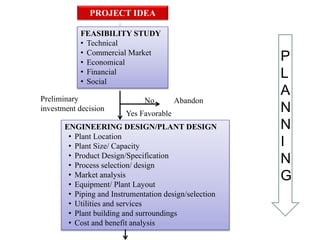

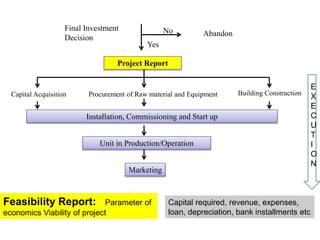

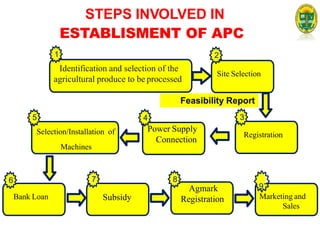

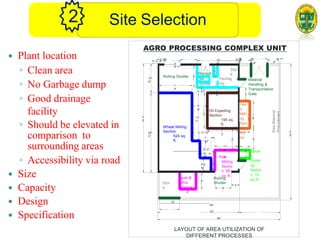

3. Establishing an APC involves identifying crops, selecting a site, registering the