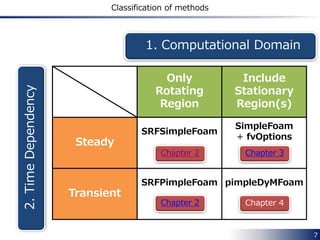

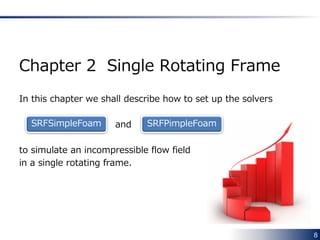

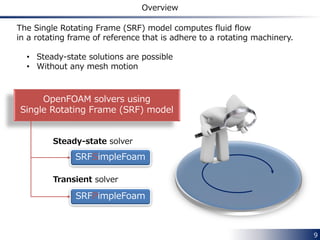

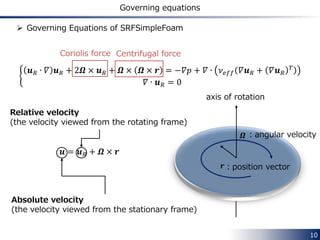

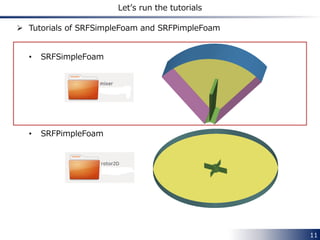

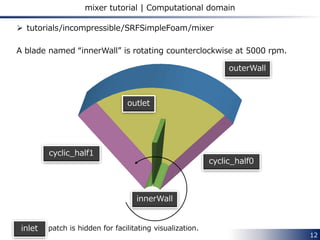

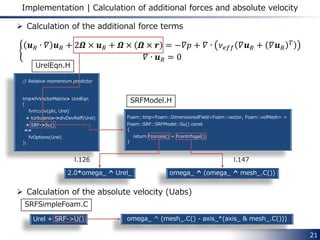

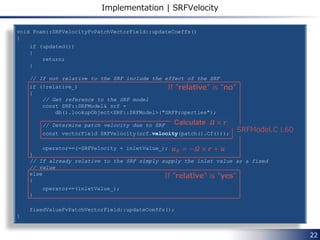

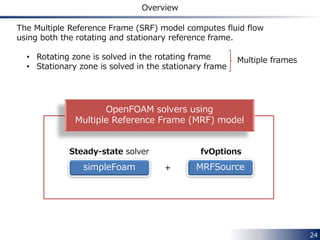

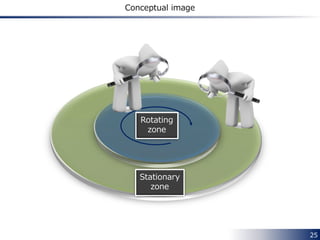

This document discusses setting up CFD simulations for rotating machinery using OpenFOAM. It describes the Single Rotating Frame (SRF) and Multiple Reference Frame (MRF) methods. The SRF method computes the flow in a single rotating frame of reference attached to the rotating machinery, allowing for steady-state or transient solutions without mesh motion. The MRF method computes the flow using both rotating and stationary frames, with the rotating zone solved in the rotating frame and stationary zones in the stationary frame. Tutorial cases for the SRF solvers SRFSimpleFoam and SRFPimpleFoam are presented to demonstrate implementing rotating boundary conditions and calculating additional force terms.

![16

SRFProperties

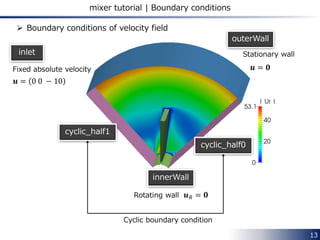

Angular velocity condition is described in SRFProperties file.

/*--------------------------------*- C++ -*----------------------------------*¥

| ========= | |

| ¥¥ / F ield | OpenFOAM: The Open Source CFD Toolbox |

| ¥¥ / O peration | Version: 2.3.0 |

| ¥¥ / A nd | Web: www.OpenFOAM.org |

| ¥¥/ M anipulation | |

¥*---------------------------------------------------------------------------*/

FoamFile

{

version 2.0;

format ascii;

class dictionary;

location "constant";

object SRFProperties;

}

// * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * //

SRFModel rpm;

axis ( 0 0 1 );

rpmCoeffs

{

rpm 5000;

}

// ************************************************************************* //

Angular velocity is specified

in terms of revolutions-per-minute [rpm]

Axis of rotation

5000 rpm ⇒ 5000 ∗ 2π 60 = 523.6 [rad/s]

When the axis vector points to you

• rpm>0 ⇒ rotation in counterclockwise direction

• rpm<0 ⇒ rotation in clockwise direction

Rotational direction](https://image.slidesharecdn.com/openfoamrotatinggeometryenglish20140518-140517222323-phpapp01/85/CFD-for-Rotating-Machinery-using-OpenFOAM-16-320.jpg)

![18

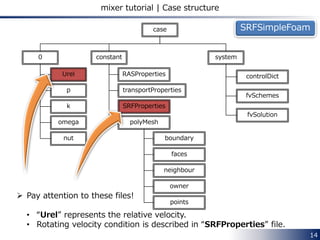

Closer look at the velocity on outerWall

In the stationary coordinate system

In the rotating coordinate system

Radius of outerWall is 0.1 m

𝒖𝐼 = 𝟎

𝒖 𝒓 = 𝒖𝐼 − 𝛀 × 𝒓

= 523.6 ∙ 0.1 = 52.36 [𝑚/𝑠]

Vectors show 𝒖 𝑟

Rotational direction](https://image.slidesharecdn.com/openfoamrotatinggeometryenglish20140518-140517222323-phpapp01/85/CFD-for-Rotating-Machinery-using-OpenFOAM-18-320.jpg)

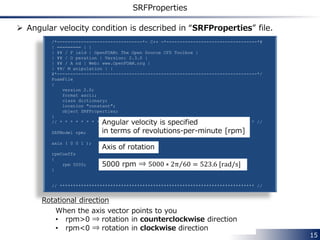

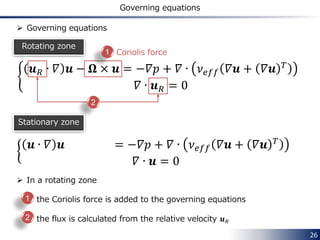

![29

Governing equations

𝛻 ∙ 𝒖 𝑅 𝒖𝐼 + 𝛀 × 𝒖𝐼 = −𝛻𝑝 + 𝛻 ∙ 𝜈 𝑒𝑓𝑓 𝛻𝒖𝐼 + 𝛻𝒖𝐼

𝑇

𝛻 ∙ 𝒖 𝑅 = 0

In each rotating zone

• the Coriolis force is added to the governing equations

• the flux is calculated from the relative velocity 𝒖 𝑅

Governing equations [1]

Coriolis force

𝛻 ∙ 𝒖𝐼 𝒖𝐼 − 𝛀 × 𝒖 = −𝛻𝑝 + 𝛻 ∙ 𝜈 𝑒𝑓𝑓 𝛻𝒖𝐼 + 𝛻𝒖𝐼

𝑇

𝛻 ∙ 𝒖𝐼 = 0

Rotating zone

Stationary zone

1

2

1

2](https://image.slidesharecdn.com/openfoamrotatinggeometryenglish20140518-140517222323-phpapp01/85/CFD-for-Rotating-Machinery-using-OpenFOAM-29-320.jpg)

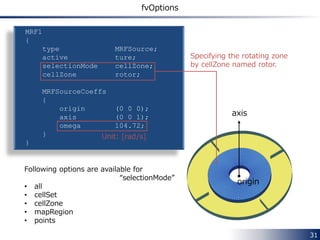

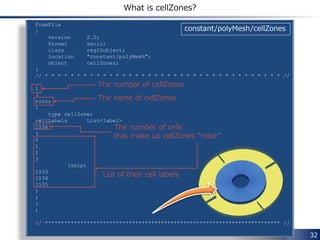

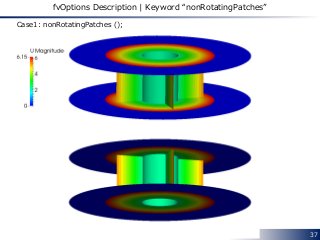

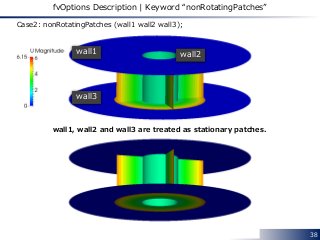

![34

fvOptions Description

MRF1

{

type MRFSource;

active ture;

selectionMode cellZone;

cellZone rotor;

MRFSourceCoeffs

{

nonRotatingPatches ();

origin (0 0 0);

axis (0 0 1);

omega 104.72;

}

}

Specifying the rotating zone

by cellZone named rotor.

Unit: [rad/s]

axis

Following options are available for

“selectionMode”

• all

• cellSet

• cellZone

• mapRegion

• points

origin

system/fvOptions](https://image.slidesharecdn.com/openfoamrotatinggeometryenglish20140518-140517222323-phpapp01/85/CFD-for-Rotating-Machinery-using-OpenFOAM-34-320.jpg)

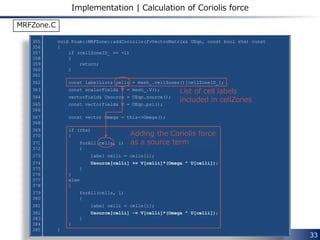

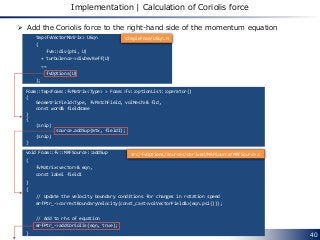

![void Foam::MRFZone::addCoriolis(fvVectorMatrix& UEqn, const bool rhs) const

{

if (cellZoneID_ == -1)

{

return;

}

const labelList& cells = mesh_.cellZones()[cellZoneID_];

const scalarField& V = mesh_.V();

vectorField& Usource = UEqn.source();

const vectorField& U = UEqn.psi();

const vector Omega = this->Omega();

if (rhs)

{

forAll(cells, i)

{

label celli = cells[i];

Usource[celli] += V[celli]*(Omega ^ U[celli]);

}

}

else

{

forAll(cells, i)

{

label celli = cells[i];

Usource[celli] -= V[celli]*(Omega ^ U[celli]);

}

}

}

41

Implementation | Calculation of Coriolis force

List of cell labels

included in the cell zone

Adding the Coriolis force

to the right-hand

side as a source term

−𝛀 × 𝒖

src/finiteVolume/cfdTools/general/MRF/MRFZone.C](https://image.slidesharecdn.com/openfoamrotatinggeometryenglish20140518-140517222323-phpapp01/85/CFD-for-Rotating-Machinery-using-OpenFOAM-41-320.jpg)

![42

Implementation | Calculation of face flux

Classify all faces into three groups (faceType = 0, 1, 2)

• For internal faces

void Foam::MRFZone::setMRFFaces()

{

const polyBoundaryMesh& patches = mesh_.boundaryMesh();

labelList faceType(mesh_.nFaces(), 0);

const labelList& own = mesh_.faceOwner();

const labelList& nei = mesh_.faceNeighbour();

// Cells in zone

boolList zoneCell(mesh_.nCells(), false);

if (cellZoneID_ != -1)

{

const labelList& cellLabels = mesh_.cellZones()[cellZoneID_];

forAll(cellLabels, i)

{

zoneCell[cellLabels[i]] = true;

}

}

label nZoneFaces = 0;

for (label faceI = 0; faceI < mesh_.nInternalFaces(); faceI++)

{

if (zoneCell[own[faceI]] || zoneCell[nei[faceI]])

{

faceType[faceI] = 1;

nZoneFaces++;

}

}

faceType = 1

Either owner or neighbour cell

is in the cell zone

src/finiteVolume/cfdTools/general/MRF/MRFZone.C](https://image.slidesharecdn.com/openfoamrotatinggeometryenglish20140518-140517222323-phpapp01/85/CFD-for-Rotating-Machinery-using-OpenFOAM-42-320.jpg)

![43

Implementation | Calculation of face flux

• For boundary faces

labelHashSet excludedPatches(excludedPatchLabels_);

forAll(patches, patchI)

{

const polyPatch& pp = patches[patchI];

if (pp.coupled() || excludedPatches.found(patchI))

{

forAll(pp, i)

{

label faceI = pp.start()+i;

if (zoneCell[own[faceI]])

{

faceType[faceI] = 2;

nZoneFaces++;

}

}

}

else if (!isA<emptyPolyPatch>(pp))

{

forAll(pp, i)

{

label faceI = pp.start()+i;

if (zoneCell[own[faceI]])

{

faceType[faceI] = 1;

nZoneFaces++;

}

}

}

}

Coupled patch face

or excluded patch face

whose owner cell is

in the cell zone

Normal patch face

whose owner cell is

in the cell zone

faceType = 2

faceType = 1](https://image.slidesharecdn.com/openfoamrotatinggeometryenglish20140518-140517222323-phpapp01/85/CFD-for-Rotating-Machinery-using-OpenFOAM-43-320.jpg)

![44

Implementation | Calculation of face flux

Create two lists of face labels per patch

//- Outside faces (per patch) that move with the MRF

labelListList includedFaces_;

//- Excluded faces (per patch) that do not move with the MRF

labelListList excludedFaces_;

forAll(patches, patchi)

{

const polyPatch& pp = patches[patchi];

forAll(pp, patchFacei)

{

label faceI = pp.start() + patchFacei;

if (faceType[faceI] == 1)

{

includedFaces_[patchi][nIncludedFaces[patchi]++] = patchFacei;

}

else if (faceType[faceI] == 2)

{

excludedFaces_[patchi][nExcludedFaces[patchi]++] = patchFacei;

}

}

}

includedFaces_[patchi][i] = local label of ith face whose faceType = 1

on the patchith patch

excludedFaces_[patchi][i] = local label of ith face whose faceType = 2

on the patchith patch

src/finiteVolume/cfdTools/general/MRF/MRFZone.C](https://image.slidesharecdn.com/openfoamrotatinggeometryenglish20140518-140517222323-phpapp01/85/CFD-for-Rotating-Machinery-using-OpenFOAM-44-320.jpg)

.makeRelative(phi);

}

} src/fvOptions/fvOptions/fvOptionList.C

void Foam::fv::MRFSource::makeRelative(surfaceScalarField& phi) const

{

mrfPtr_->makeRelative(phi);

} src/fvOptions/sources/derived/MRFSource/MRFSource.C

void Foam::MRFZone::makeRelative(surfaceScalarField& phi) const

{

makeRelativeRhoFlux(geometricOneField(), phi);

}

src/finiteVolume/cfdTools/general/MRF/MRFZone.C](https://image.slidesharecdn.com/openfoamrotatinggeometryenglish20140518-140517222323-phpapp01/85/CFD-for-Rotating-Machinery-using-OpenFOAM-45-320.jpg)

![46

Implementation | Calculation of face flux

template<class RhoFieldType>

void Foam::MRFZone::makeRelativeRhoFlux

(

const RhoFieldType& rho,

surfaceScalarField& phi

) const

{

const surfaceVectorField& Cf = mesh_.Cf();

const surfaceVectorField& Sf = mesh_.Sf();

const vector Omega = omega_->value(mesh_.time().timeOutputValue())*axis_;

const vectorField& Cfi = Cf.internalField();

const vectorField& Sfi = Sf.internalField();

scalarField& phii = phi.internalField();

// Internal faces

forAll(internalFaces_, i)

{

label facei = internalFaces_[i];

phii[facei] -= rho[facei]*(Omega ^ (Cfi[facei] - origin_)) & Sfi[facei];

}

makeRelativeRhoFlux(rho.boundaryField(), phi.boundaryField());

}

src/finiteVolume/cfdTools/general/MRF/MRFZoneTemplates.C

Modification of the internal face flux

Modification of the

boundary face flux

• “internalFaces_” is a label list of the internal faces whose owner or neighbour

cell is in the rotating cell zone.

• According to the governing equation, the face fluxes of these internal faces

are modified by subtracting 𝜴 × 𝒓 ∙ 𝑺 𝑓 from the absolute face fluxes:

𝒖 𝑅 ∙ 𝑺 𝑓 = 𝒖𝐼 ∙ 𝑺 𝑓 − (𝜴 × 𝒓) ∙ 𝑺 𝑓](https://image.slidesharecdn.com/openfoamrotatinggeometryenglish20140518-140517222323-phpapp01/85/CFD-for-Rotating-Machinery-using-OpenFOAM-46-320.jpg)

![47

Implementation | Calculation of face flux

template<class RhoFieldType>

void Foam::MRFZone::makeRelativeRhoFlux

(

const RhoFieldType& rho,

FieldField<fvsPatchField, scalar>& phi

) const

{

const surfaceVectorField& Cf = mesh_.Cf();

const surfaceVectorField& Sf = mesh_.Sf();

const vector Omega = omega_->value(mesh_.time().timeOutputValue())*axis_;

// Included patches

forAll(includedFaces_, patchi)

{

forAll(includedFaces_[patchi], i)

{

label patchFacei = includedFaces_[patchi][i];

phi[patchi][patchFacei] = 0.0;

}

}

// Excluded patches

forAll(excludedFaces_, patchi)

{

forAll(excludedFaces_[patchi], i)

{

label patchFacei = excludedFaces_[patchi][i];

phi[patchi][patchFacei] -=

rho[patchi][patchFacei]

* (Omega ^ (Cf.boundaryField()[patchi][patchFacei] - origin_))

& Sf.boundaryField()[patchi][patchFacei];

}

}

}

src/finiteVolume/cfdTools/general/MRF/MRFZoneTemplates.C

Relative face fluxes

on rotating patches are zero

𝒖 𝑅 ∙ 𝑺 𝑓 = 0

Relative face fluxes

on stationary patches

in the rotating cell zone

is calculated by subtracting

𝜴 × 𝒓 ∙ 𝑺 𝑓 from the absolute

face fluxes](https://image.slidesharecdn.com/openfoamrotatinggeometryenglish20140518-140517222323-phpapp01/85/CFD-for-Rotating-Machinery-using-OpenFOAM-47-320.jpg)

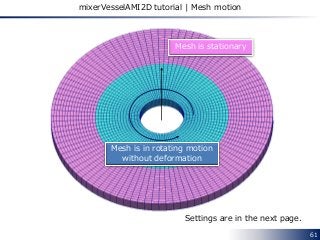

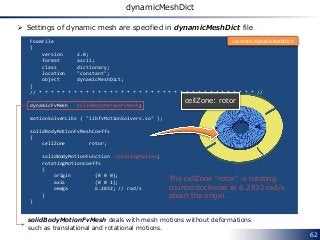

![63

solidBodyMotionFvMesh

The following motions (solidBodyMotionFunction) are available for

solidBodyMotionFvMesh

• linearMotion

• oscillatingLinearMotion

• rotatingMotion

• axisRotationMotion

• oscillatingRotatingMotion

• SDA [4]

• multiMotion

Code: src/dynamicFvMesh/solidBodyMotionFvMesh/solidBodyMotionFunctions

Translational motion

Rotational motion

Ship Design Analysis

Combination of the above motions](https://image.slidesharecdn.com/openfoamrotatinggeometryenglish20140518-140517222323-phpapp01/85/CFD-for-Rotating-Machinery-using-OpenFOAM-63-320.jpg)

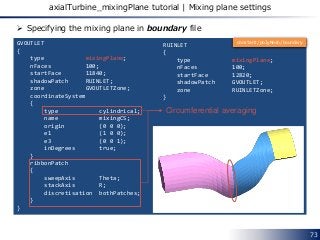

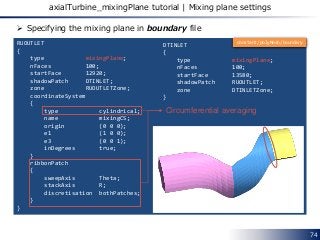

![ What is the ribbonPatch? [5]

According to [6]

the ribbon patch will specify the direction in which it will perform the

average (sweepAxis) and in which direction it will stack the cells

(stackAxis).

75

axialTurbine_mixingPlane tutorial | Mixing plane settings

ribbonPatch

{

sweepAxis Theta;

stackAxis R;

discretisation bothPatches;

}

R

Theta](https://image.slidesharecdn.com/openfoamrotatinggeometryenglish20140518-140517222323-phpapp01/85/CFD-for-Rotating-Machinery-using-OpenFOAM-75-320.jpg)

![77

axialTurbine_mixingPlane tutorial | MRFZones

1

(

rotor

{

// Fixed patches (by default they 'move' with the MRF zone)

nonRotatingPatches ( RUSHROUD );

origin origin [0 1 0 0 0 0 0] (0 0 0);

axis axis [0 0 0 0 0 0 0] (0 0 1);

omega omega [0 0 -1 0 0 0 0] -10;

}

)

Specifying the rotating zone in MRFZones file

rotor

Name of rotating cellZones

The absolute velocity on the

“nonRotatingPatches” is 0.

constant/MRFZones](https://image.slidesharecdn.com/openfoamrotatinggeometryenglish20140518-140517222323-phpapp01/85/CFD-for-Rotating-Machinery-using-OpenFOAM-77-320.jpg)

![78

History of development

[7]](https://image.slidesharecdn.com/openfoamrotatinggeometryenglish20140518-140517222323-phpapp01/85/CFD-for-Rotating-Machinery-using-OpenFOAM-78-320.jpg)

![81

References

[1] http://openfoamwiki.net/index.php/See_the_MRF_development

[2] CFD for Underhood Modeling

http://publications.lib.chalmers.se/records/fulltext/204821/204821.pdf

[3] http://www.sourceflux.de/blog/software-design-fvoptions/

[4] Roll Motion of a Box and Interaction with Free-Surface

http://www.tfd.chalmers.se/~hani/kurser/OS_CFD_2009/ArashEslamdoost/RollMotionofaBoxa

ndInteractionwithFreeSurface.pdf

[5] Martin Beaudoin, Inside the mixingPlane interface

ftp://ftp.heanet.ie/disk1/sourceforge/o/op/openfoam-

extend/OpenFOAM_Workshops/OFW7_2012_Darmstadt/Workshop-

Documents/CommunityDay/SIG-Turbo/Final-MartinBeaudoin-

OFTurboWGInsideTheMixingPlaneInterfac (accessed 06/13/2015)

[6] Ant´onio Jo˜ao Ferreira Reis, Validation of NASA Rotor 67 with OpenFOAM’s Transonic

Density-Based solver

http://run.unl.pt/bitstream/10362/9930/1/Reis_2013.pdf (accessed 06/13/2015)

[7] Evaluation of an improved mixing plane interface for OpenFOAM

http://publications.lib.chalmers.se/records/fulltext/201855/local_201855.pdf

[8] Taking the mixingPlane interface for a ride

http://download2.polytechnic.edu.na/pub4/sourceforge/o/op/openfoam-

extend/OpenFOAM_Workshops/OFW9_2014_Zagreb/Presentations/Hakan_Nilsson_OFW09_P_

0046.pdf](https://image.slidesharecdn.com/openfoamrotatinggeometryenglish20140518-140517222323-phpapp01/85/CFD-for-Rotating-Machinery-using-OpenFOAM-81-320.jpg)

![82

References

[9] Density Based Navier Stokes Solver for Transonic Flows

http://www.personal.psu.edu/dab143/OFW6/Presentations/oliver_borm_slides.pdf](https://image.slidesharecdn.com/openfoamrotatinggeometryenglish20140518-140517222323-phpapp01/85/CFD-for-Rotating-Machinery-using-OpenFOAM-82-320.jpg)