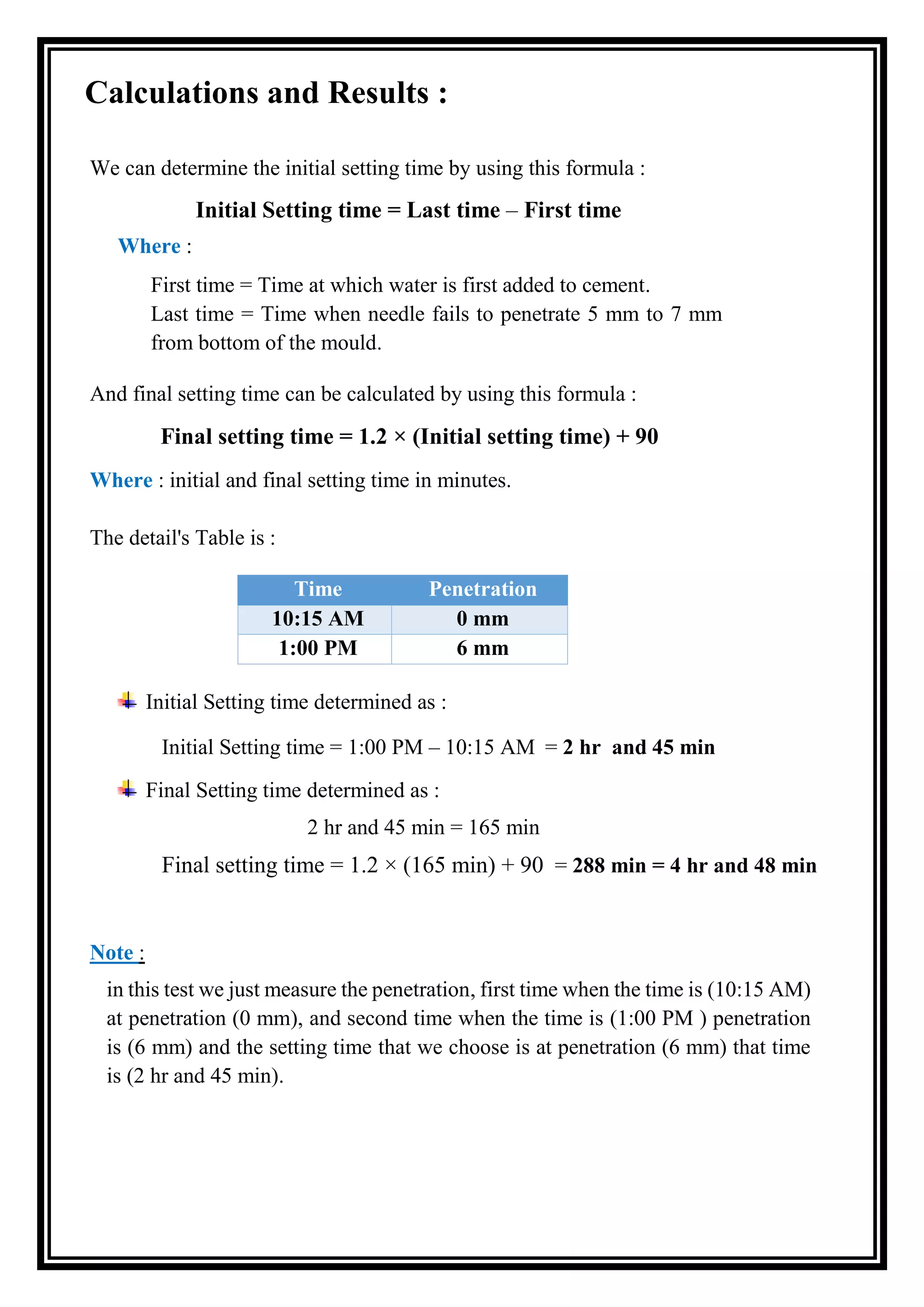

This report details an experiment to determine the initial and final setting times of a hydraulic cement using the Vicat needle test method. The cement paste was prepared and tested according to ASTM standards. The initial setting time was found to be 2 hours and 45 minutes when the needle penetration was 6 mm. The final setting time was then calculated using an empirical equation to be 4 hours and 48 minutes. While only two penetration measurements were taken, the results indicate the cement would be suitable for construction uses and meet the Iraqi standard of a minimum 1 hour initial setting time.