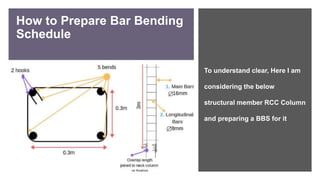

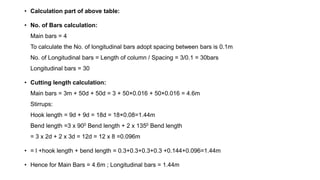

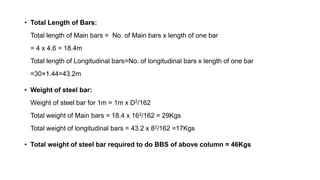

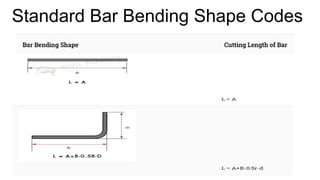

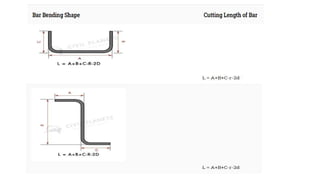

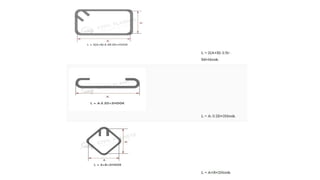

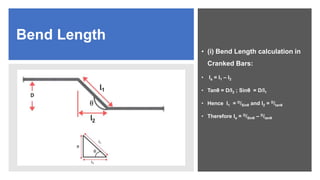

This document provides information and formulas for calculating bar bending schedules. It discusses hook length, bend length, overlap length, and how to prepare a bar bending schedule table. Formulas are given for calculating hook length, bend length for cranked and corner bars, and overlap length for tension and compression members. An example bar bending schedule is also shown for a sample RCC column, calculating the number of bars, cutting lengths, total bar lengths, and total steel weight required.

![Overlap Length /

Lap Length in

Reinforcement:-

• Overlap Length for compression

members (columns) = 50D

• The Overlap Length for tension

members (beams) = 40D

[D is the Diameter of the bar]](https://image.slidesharecdn.com/barbendingschedule-230904083924-6b776842/85/BAR-BENDING-SCHEDULE-pptx-10-320.jpg)