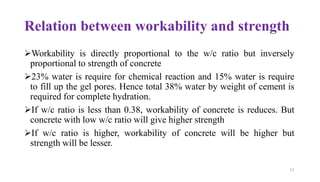

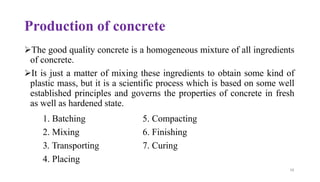

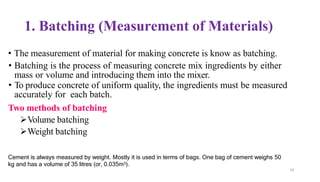

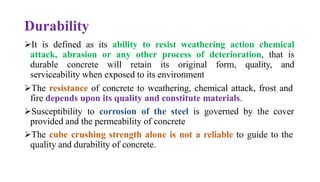

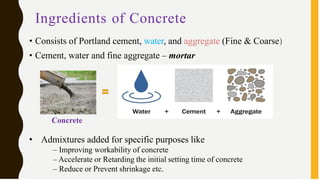

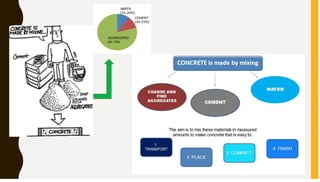

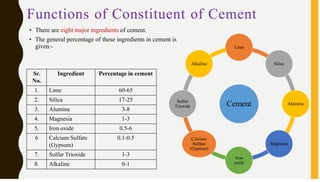

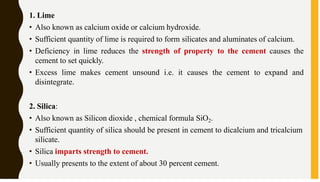

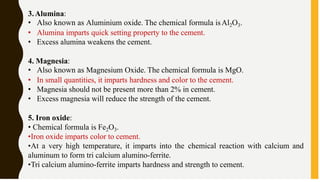

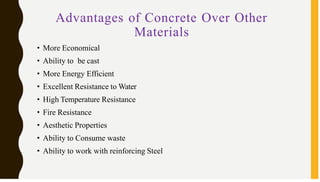

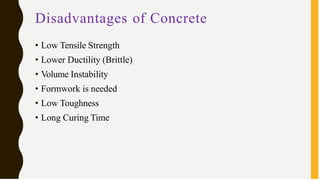

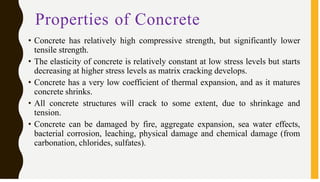

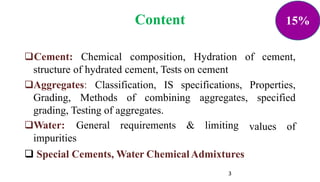

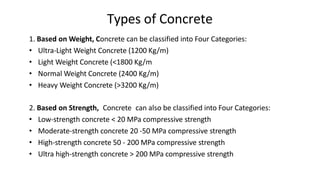

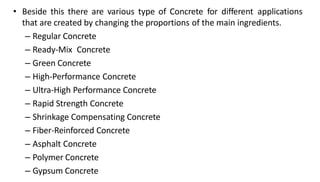

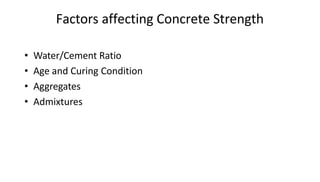

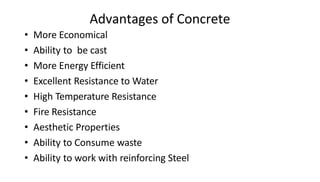

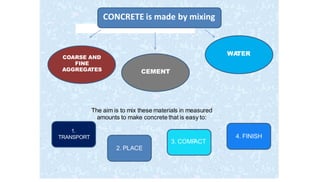

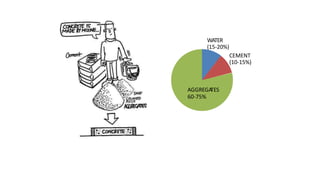

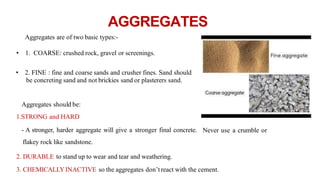

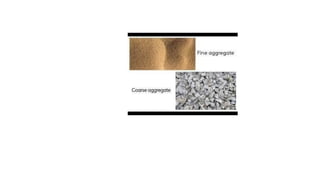

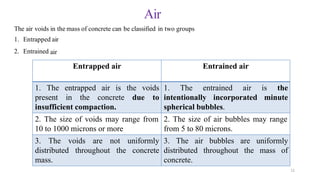

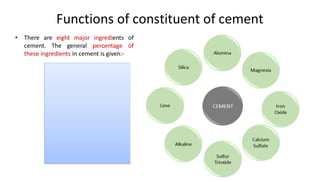

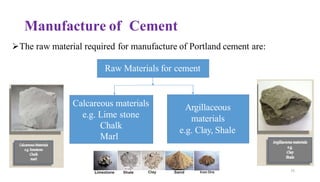

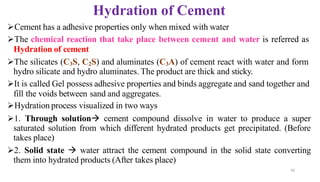

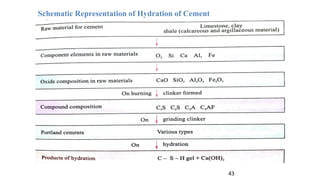

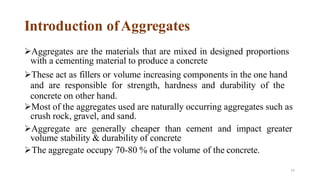

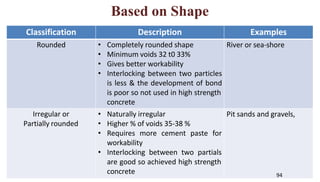

The document discusses concrete technology, detailing its composition, properties, advantages, and disadvantages, as well as advancements in sustainability. Concrete, primarily composed of cement, water, and aggregates, is a crucial construction material with high compressive strength but low tensile strength. It also emphasizes the need for sustainable practices in concrete production due to its significant environmental impact and highlights various innovations to improve its sustainability.

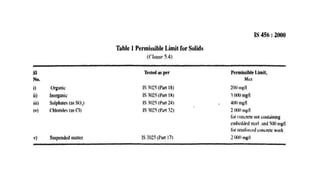

![• BIS 2000 Standard

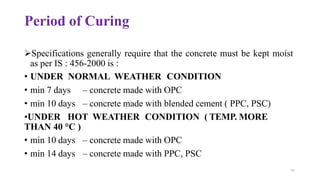

IS 456 (2000): Plain and Reinforced Concrete - Code of

Practice [CED 2: Cement and Concrete]

Books:

• Concrete technology theory and practice by ms Shetty

• Concrete technology by Dr. R.P Rethaliya

2](https://image.slidesharecdn.com/3150610studymaterialcivilengineeringunit-01-250129114215-e474aa6a/85/3150610Study-MaterialCivil-EngineeringUnit-01-pdf-28-320.jpg)

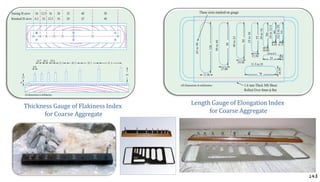

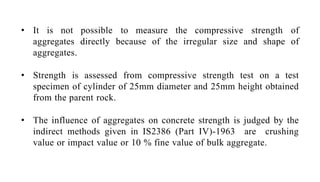

![Flakiness & Elongation Index

[IS 2386-1963- PART-1]

• Flaky particle ( Thickness)= least dimension is < 0.6 time of its mean dimension

• Its measure in %

• Elongated Particle (Length)= its length is > 1.8 times its mean dimension

• More than 40%- 45% is undesirable

• These tests are not applicable to sizes larger than 6.3 mm.

141](https://image.slidesharecdn.com/3150610studymaterialcivilengineeringunit-01-250129114215-e474aa6a/85/3150610Study-MaterialCivil-EngineeringUnit-01-pdf-167-320.jpg)

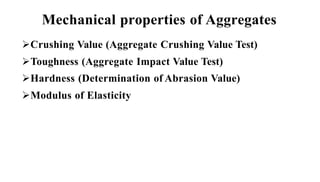

![1. Take sufficient quantity of aggregate to provide at least 200 pieces of any fraction to be tested.

2. Sieve the sample through sieves as shown in observations table.

3. Separate particles retained on the prescribed sieves.

4.Try to pass each aggregate particle through the corresponding slot of thickness gauge Fig. The aggregate piece

passing through 50 mm and retained on 40 mm sieve, should only be passed through {(50+40)/2} x 0.6 = 27.0

mm slot. If the aggregate passes through this 27.0 mm slot; then the aggregate piece is flaky.

5. Weigh all the pieces which pass through this slot.

6. Calculate the flakiness index = Wt. of material passing through the thickness gauge/Total weight of sample

For Elongation Index:

1. Sieve the sample through I.S., sieve as specified in observation table.

2. Separate aggregate pieces retained on sieves.

3. Try to pass each aggregate piece through the corresponding slot of length gauge (Fig.). If the length of the

particle {(50+40)/2} x 1.8 = 81 mm, it is said to have retained on the length gauge.

4. Weigh all such pieces

5.Calculate the elongation index as follows ― = (weight of material retained on the length gauge/total weight of

the sample gauge) x 100

Suppose the aggregate particle passes through 50 mm sieved and retained on 40 mm sieve, then ―

Flaky /thickness gauge = [(50 + 40)/2] x 0.6 = 27.0 mm

Elongation / length gauge = [(50 + 40)/2] x 1.8 = 81 m

For Flakiness Index](https://image.slidesharecdn.com/3150610studymaterialcivilengineeringunit-01-250129114215-e474aa6a/85/3150610Study-MaterialCivil-EngineeringUnit-01-pdf-168-320.jpg)