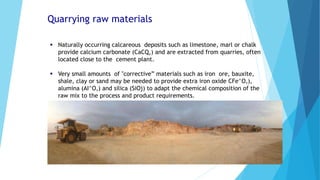

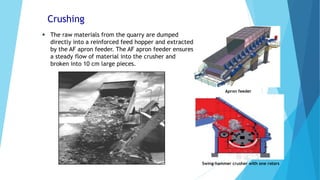

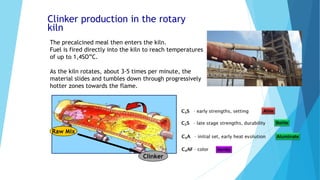

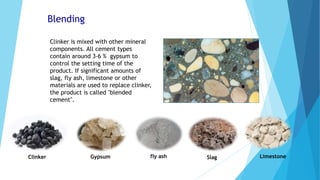

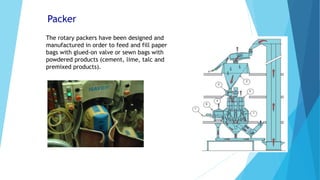

This document outlines the process for manufacturing cement. It begins with quarrying raw materials like limestone and transporting them to the plant for crushing. The crushed materials are then homogenized and ground into raw meal. The raw meal goes through preheating and precalcining before being fired in a rotary kiln at high temperatures to produce clinker. The clinker is cooled, stored and later ground with gypsum and other additives to produce cement powder. The final cement is stored in silos and packed into bags for transport to customers. The process aims to efficiently produce cement from raw materials through steps like preheating and using modern technologies for grinding.