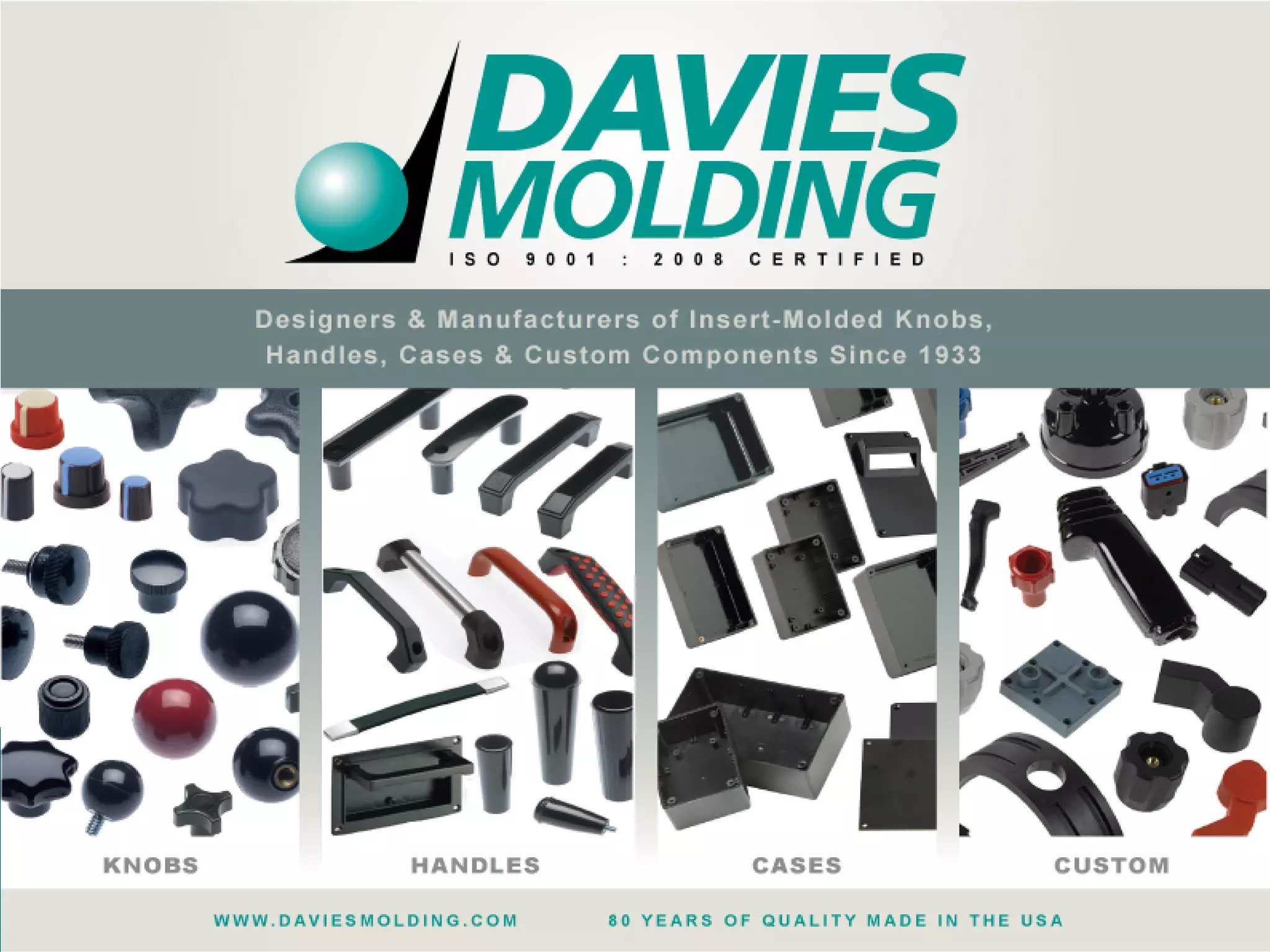

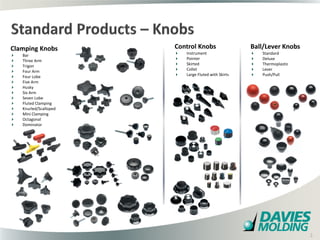

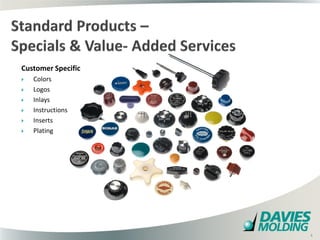

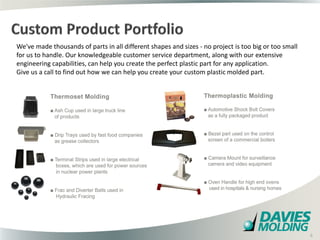

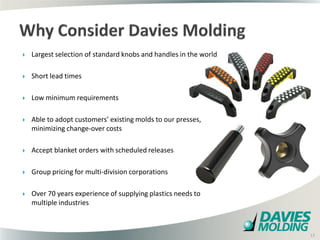

Davies Mold Solutions has 80 years of experience designing and manufacturing plastic components. They specialize in insert molding and provide custom molding and modifications. They are ISO 9001:2008 certified and manufacture standard and custom plastic knobs, handles, and other parts for various industries. Davies has extensive engineering capabilities and can help design custom plastic parts for any application.