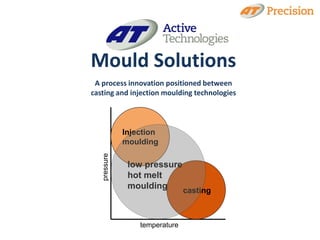

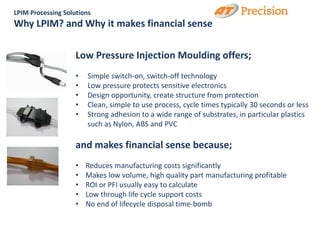

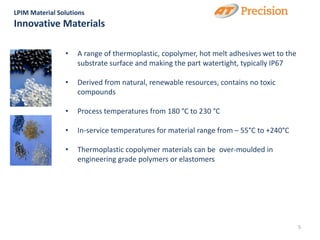

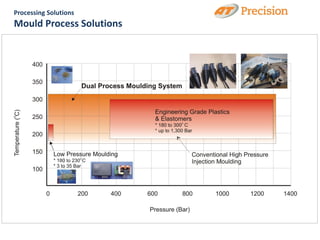

The document provides an overview of the services and technologies offered by a company specializing in low pressure injection moulding (LPIM) and associated mould solutions. It highlights the advantages of LPIM, such as reduced manufacturing costs, fast cycle times, and environmentally friendly materials, while detailing various processing solutions and equipment. Additionally, it emphasizes the importance of a skilled development team for tailored applications and the integration of advanced technologies into manufacturing processes.