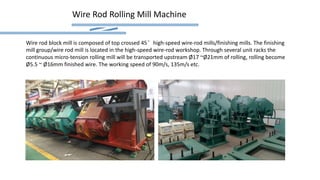

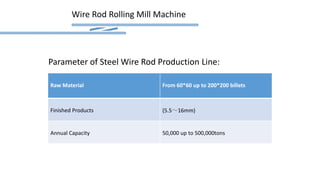

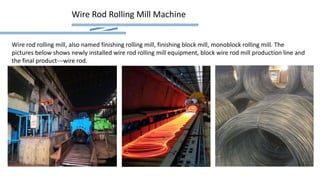

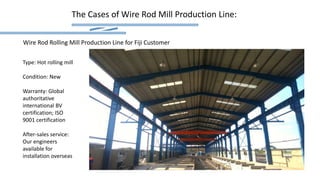

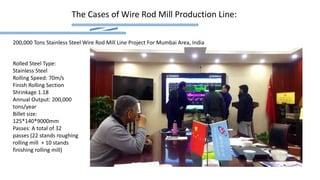

The document outlines the capabilities of a Chinese manufacturer specializing in wire rod rolling mills and related equipment, providing services from design to commissioning. It describes the specifications, functionalities, and structural characteristics of the wire rod rolling mill, including performance details like production capacity and operating speeds. Additionally, the company offers comprehensive support, including installation, technical services, and customization based on user requirements.