CARGO OIL PUMPING SYSTEM.pdf

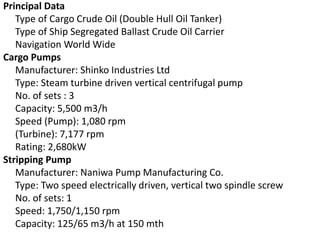

- 1. Principal Data Type of Cargo Crude Oil (Double Hull Oil Tanker) Type of Ship Segregated Ballast Crude Oil Carrier Navigation World Wide Cargo Pumps Manufacturer: Shinko Industries Ltd Type: Steam turbine driven vertical centrifugal pump No. of sets : 3 Capacity: 5,500 m3/h Speed (Pump): 1,080 rpm (Turbine): 7,177 rpm Rating: 2,680kW Stripping Pump Manufacturer: Naniwa Pump Manufacturing Co. Type: Two speed electrically driven, vertical two spindle screw No. of sets: 1 Speed: 1,750/1,150 rpm Capacity: 125/65 m3/h at 150 mth

- 2. Crude Oil Stripping Eductors Manufacturer: Teamtec No. of sets: 2 Capacity: 620 m3/h at 150 mth Driving fluid: 1,075 m3/h at 12 kg/cm2 Ballast Pump No.1 Manufacturer: Shinko Industries Ltd. Type: Centrifugal, vertical single stage Prime mover: Electric motor Capacity: 3,000 m3/h Total head: 35m Ballast Pump No.2 Manufacturer: Shinko Industries Ltd. Type: Centrifugal, vertical single stage Prime mover: Steam turbine Capacity: 3,000 m3/h Total head: 35m Speed: (Pump): 1,170 rpm (Turbine): 7,548 rpm

- 3. Water Ballast Stripping Eductors Manufacturer: Teamtec No. of sets: 2 Capacity: 200 m3/h Driving water: 1,040m3/h at 3.5 kg/cm2 supplied by either of the ballast pumps

- 9. COP Stbd Slop Tk Port Slop Tk COT COW

- 12. ODMCS Operation

- 14. ppm x m3/hr Litres per nm = ----------------------------------- 1000000 x 1000 x spd (nm/hr)

- 15. open shut

- 16. > 30 l /nm

- 17. CARGO OIL PUMPING SYSTEM CARGO OIL PUMPS & WATER BALLAST PUMPS STEAM TURBINES (COPT & WBPT) CARGO OIL STRIPPING PUMP AUTOMATIC VACUUM STRIPPING SYSTEM (AVSS)

- 18. Materials - NI-AI-Bronze - pump casing and Impeller. The cartridge-type mechanical seal facilities easy maintenance.

- 19. Principal particulars of cargo pump • Normal capacity – 1800 to 6050 cum/hr • Total Head – 150 m • Speed – 2000 to 1150 rpm • Suction bore – 400 to 700 mm • Discharge bore – 300 to 500 mm

- 20. Principal particulars of water ballast pump • Normal capacity – 1200 to 5000 cum/hr • Total Head – 30 to 40m • Speed – 1180 to 890 rpm • Suction bore – 350 to 700 mm • Discharge bore – 300 to 500 mm

- 22. Features of marine pumps • Vertical, single stage, double suction, double volute, driven by single vertical steam turbine via intermediate shaft through bulkhead stuffing box which keeps the engine room gas tight • Pump casing is vertically split Into two halves at the shaft centre line, and Joined surfaces include non asbestos seat packing. • The suction and discharge nozzles are both provided in the rear half of the casing and both are open in the horizontal direction 90 degrees apart, so that dismantling or reassembling can be performed easily without disturbing the suction and discharge piping. • Double volute minimizes the radial thrust. While in a double volute the pressures are not uniform at partial capacity operation the resulting forces essentially balance each other which results in low deflection at all operating points, thus reducing packing wear, ring wear and bearing loading. • Double suction also balances the axial hydraulic thrust and provides for good suction performance due reduced NPSH • The pump shaft is supported by ball bearing at upper and lower points. The impeller nut threads are opposite to direction of shaft rotation to prevent from loosening • Casing is equipped with wear rings inserted in the groove of the casing wall

- 23. • Bulkhead stuffing box for the intermediate shaft seals the gas passing from the pump room. • The intermediate shafts are divided Into two parts, the upper and the lower portions, rigidly supported by two ball bearings in the stuffing box. • the lower shaft is coupled with gear coupling which is of spline type and the length can be adjusted.

- 24. • Pump protection - To prevent any accident such as explosion or for the parameters can be monitored through a turbine gauge board and also through CCR Protection Set value Alarm Trip Pump casing overheat 75 0C 80 0C Pump bearing overheat 85 0C 90 0C Pump vibration 16mm 18 mm Seal leakage When leaking Discharge pressure As desired

- 25. Cargo stripping pump • ·The stripping pumps are of robust design and can handle efficiently all grades or oils from petrol to viscous liquids under difficult suction conditions. • ·Air chambers are fitted on the discharge side to eliminate pipe line vibration.

- 27. Remote control system – • The pump speed is controlled by steam valve that is governed by the pneumatic speed controller. • The pump speed is monitored by the pneumatic stroke detector Speed indicator 0.2 – 1 air signal

- 28. Engine room Pump room Drain Tank To slop tank Signal air 0.2 to 1 bar Pump room Gas extraction valve

- 30. 1. Turn on the PLC 2. After starting the cargo oil pump the cargo control console : - Set the gas extraction valve switch to "NOR" - Set the vacuum pump switch to "AUTO" Set the discharge output valve to "AUTO“ 3. While the liquid level in the cargo oil tank is high, the cargo oil pump located at the bottom of the vessel performs the unloading work at the best condition because of its high suction pressure. Therefore this vacuum stripping system is not operated under this condition. 4. After unloading for a certain time, the liquid level in the cargo oil tank falls down and the suction pressure of the cargo oil pump is also decreased. Vapour generated is sucked into the separator through the suction mouth of the cargo oil tank. The vapor mixed with oil is accumulated at the top of the separator by sp gravity difference of oil and vapor. Consequently the separator level begins to fall. 5. When the oil level in the separator lowers to 50%, the bypass valve is set to close and gas extraction valve is set to open by a signal air sent from the level transmitter. At the same time, vacuum pump continuously runs and the discharge control valve is throttled.

- 31. 6. When the vapor is extracted by the vacuum pump, the separator level rises again and if it reaches 70%, the vacuum pump continuously runs, the gas extraction valve is closed, the bypass valve is opened and the discharge control valve is opened. 7. The unloading is proceeding repeatedly as mentioned above to prevent the vapor entering into the cargo oil pump whenever the vapor is accumulated in the separator. 8. If the level in the cargo oil tank lowers further, the level around the bell mouth fluctuates heavily and a lot of gas is sucked. While the separator level falls to below 5% by extremely decreasing the liquid level in the cargo oil tank, the alarm lamp indicating low separator level is displayed on the control unit. This means unloading work enters into stripping stage. 9. If this conditions is continued about 3 minutes, the finish of stripping lamp in red on the console flickers with buzzing and shows the completion of the unloading work. 10. After finishing stripping, the selector is set at "COP STOP" and the cargo oil pump is automatically stopped. Whereas it keeps on running, while at "COP RUN".