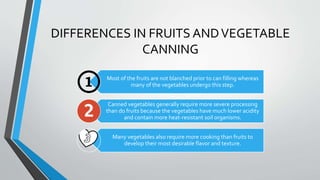

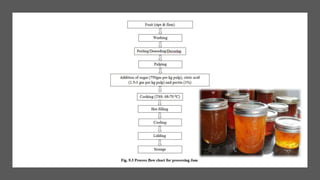

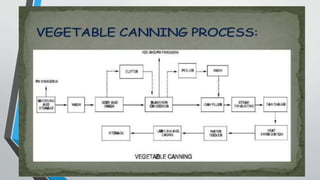

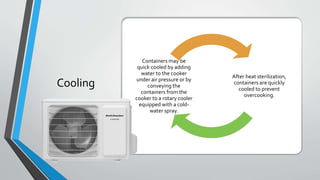

The goal of canning is to destroy microorganisms in food and prevent recontamination. Common canned foods include vegetables like beets, carrots, corn and peas as well as fruits like apples, peaches and pears. The canning process involves washing, sorting, filling containers, exhausting air, sealing, heat sterilization, cooling and labeling. Vegetables generally require more processing than fruits due to lower acidity. Modern equipment includes continuous retorts that rotate cans through pressurized heating chambers. A tomato canning case study outlines specific steps like washing, sorting, peeling, coring, filling, exhausting, sealing, heating and cooling the containers.