The document discusses the development of a non-contact surface profilometry system designed for automated geometrical dimensioning and tolerancing in quality control, particularly for steel reinforcements in concrete railroad ties. This system achieves high-resolution 3D point clouds and automated post-processing at rapid data acquisition rates using embedded microcomputers and custom circuits, significantly enhancing manufacturing quality inspection. The research highlights the system's affordability and potential for autonomous inspections, overcoming limitations of traditional measurement methods like coordinate measurement machines (CMM).

![International Journal of Engineering Inventions

e-ISSN: 2278-7461, p-ISSN: 2319-6491

Volume 3, Issue 2 (September 2013) PP: 15-19

www.ijeijournal.com Page | 15

Design of a Non-Contact Surface Profilometry System for

Automated Geometrical Dimensioning and Tolerancing

Mark Haynes1

, Levi DeLissa2

, Chih-Hang John Wu3

, B. Terry Beck4

, and

Robert J. Peterman5

1

Department of Industrial Engineering, Kansas State University, USA

2

Department of Industrial Engineering, Kansas State University, USA

3

Department of Industrial Engineering, Kansas State University, USA

4

Department of Mechanical Engineering, Kansas State University, USA

5

Department of Civil Engineering, Kansas State University, USA

ABSTRACT: A Non-Contact Surface Profilometry System has been developed for autonomous geometrical

dimensioning and tolerancing quality control. Using embedded microcomputers and custom control circuits a

cost effective system has been developed to provide high density sub-micron resolution 3-dimensional point

clouds and meshes. With a data acquisition rate of up to 200,000 samples per second large data structures are

developed quickly and manual data processing is infeasible. Software has been developed to automate the post

processing of the acquired data to provide quality control of critical dimensions of various components.

Keywords: Dimensioning, tolerancing, automation, profiling, quality, control, measurement.

I. INTRODUCTION

Geometrical dimensioning and inspection are critical for manufacturing quality control. Coordinate

Measurement Machines (CMM) are the industry standard for geometrical dimension quality control. Modern

industrial CMM machines do not offer a feasible method of performing 100% inspection on produced parts due

to the cost, limited data collection rates, and lack of autonomous feature recognition and measurement systems.

This explorative research attempts to establish a means of providing autonomous geometrical dimensioning and

inspection at a high processing rate and high scan resolution while keeping costs within practical range for

industrial application.

II. PRIOR RESEARCH

Previously, two non-contact surface profiling systems have been developed through this research. The

first system was to prove the feasibility and concept of developing a low cost profiling system while maintaining

high data resolution. The first system was built using an industrial programmable logic controller (PLC) and

using a single point laser displacement sensor to provide the sub-micron resolution measurements. The first

system was able to successfully generate 3 Dimensional point clouds of the scanned surface at a fraction of the

cost of commercially available CMM equipment. The first prototype had a data acquisition rate of 100 data

points per second.

The second prototype developed replaced the expensive PLC with an ATMega168eight bit

microcontroller. With design improvements the new prototype was able to achieve 1000 data points per second.

Issues with the commercial laser displacement sensor controller limited the overall number of data points that

could be collected as well as created timing issues[1].

The latest prototype utilizes an AM335x 1GHz ARM Cortex-A8 processor running a linux OS along

with a custom developed analog to digital converter to acquire data from the laser displacement sensor. With

this design, data collection speeds have been achieved at 28,000 samples per second during operation and the

maximum possible collection rate has been computed to be 200,000 samples per second. The low cost ARM

processor enables the developed system to sustain complete synchronization between the laser displacement

sensor data acquisition and positioning of the 3 axis traverse system.

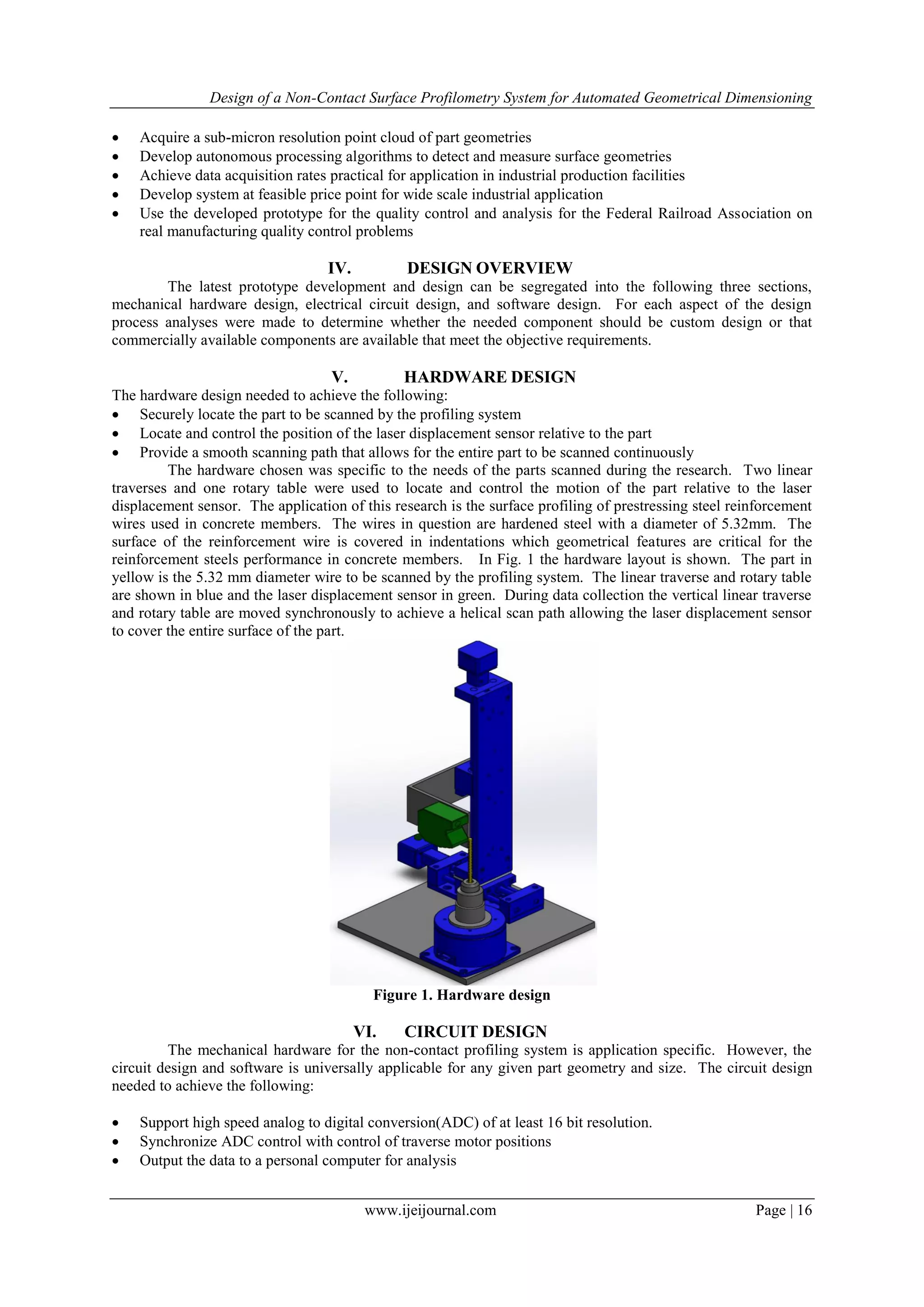

III. OBJECTIVES

The list below describes the primary objectives to be achieved through this research and design. This

research was sponsored by the Federal Railroad Association (FRA) for the analysis and quality control of steel

reinforcements used within concrete railroad ties. As such the design is tailored to the needs of the quality

control of these steel reinforcements; however, the design aspects of this research are practical for any generic

geometry part.](https://image.slidesharecdn.com/c0321519-131004235346-phpapp01/75/Design-of-a-Non-Contact-Surface-Profilometry-System-for-Automated-Geometrical-Dimensioning-and-Tolerancing-1-2048.jpg)

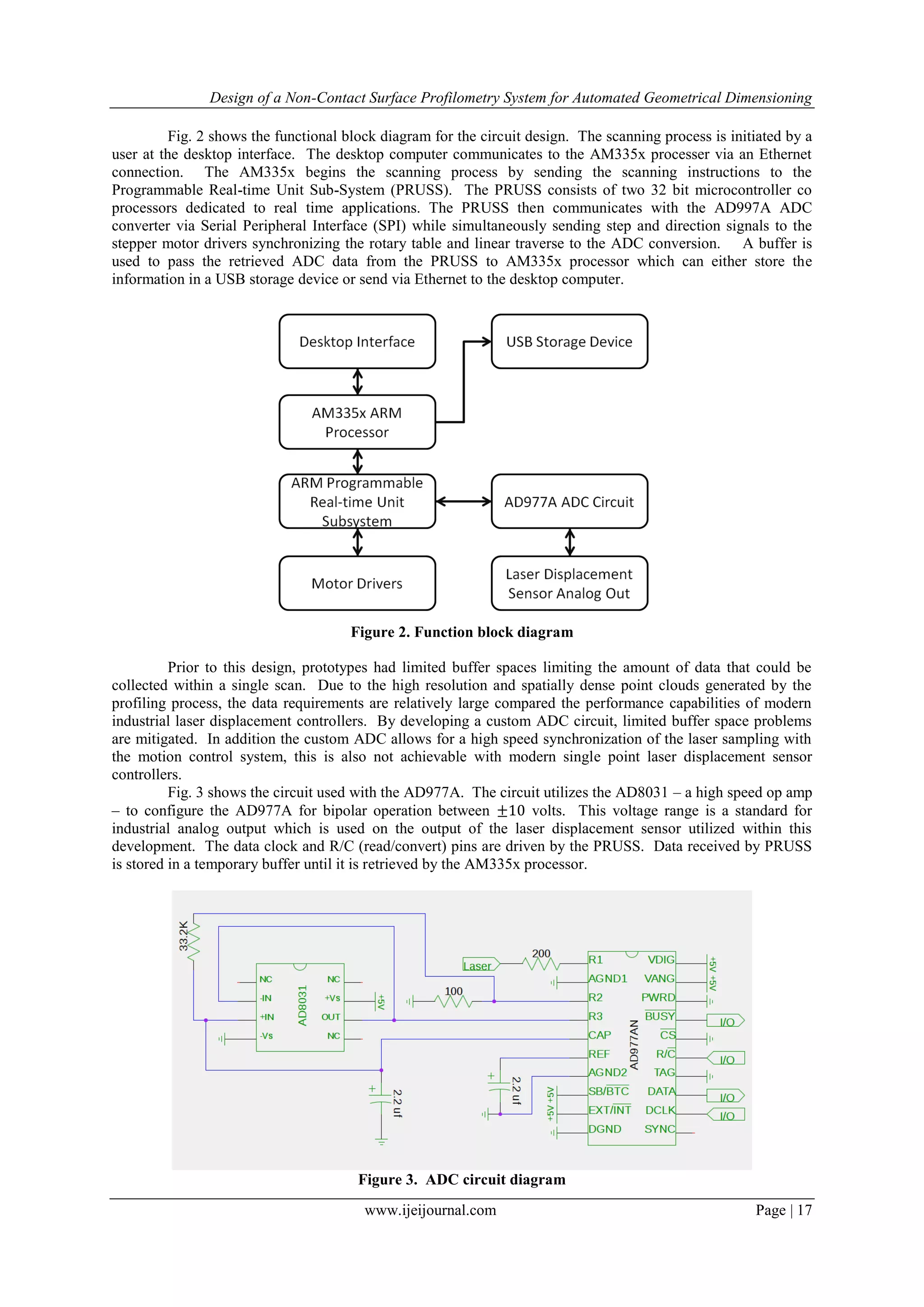

![Design of a Non-Contact Surface Profilometry System for Automated Geometrical Dimensioning

www.ijeijournal.com Page | 18

VII. SOFTWARE DESIGN

The designed software can be separated into the following three categories.

PRUSS assembly for data acquisition and motion control

AM335x C code for data transfer and interfacing the desktop computer

Desktop C/C++ code for processing collected data and performing autonomous geometrical feature

measurements

The PRUSS assembly instruction set is specifically tailored for developing real time systems where

precise timing is critical. The assembly code developed for the PRUSS assembly code is written to receive

instruction sets via a buffer from the AM335x processor. Upon receiving instructions for a scan the assembler

code generates the necessary step and direction signals for the stepper motors while processing the SPI for the

ADC. The assembly code stores ADC data in a buffer to be retrieved by the AM335x processor.

The AM335x C code provides a means of communication and data storage in-between the desktop

computer and the PRUSS. Data pulled from the PRUSS buffer is stored on a flash memory device until it is

unloaded to the desktop computer. The AM335x software additionally receives and processes all commands

from the user and desktop computer.

The last and most intricate of the software development is in creating autonomous geometrical feature

measuring algorithms capable of processing the data and obtaining surface profile measurements. Much of this

development can be seen in greater detail in “Automated real-time search and analysis algorithms for a non-

contact 3D profiling system”[2].

Each geometrical feature to be measured requires unique processing to obtain the desired measurement.

A combination of spatial correlation, non-linear search algorithms, and procedural programming methodologies

leads to automated measurement extraction[3].

VIII. RESULTS

The developed system was utilized for the surface profiling of pre stressing steel reinforcement wires to

determine the geometrical features that influence performance when the steel is used in concrete members.

With this system new geometrical features were discovered as having critical influences on concrete members

whose measurements were not obtained until this development[4]. Fig. 4 below shows a resulting 3D

model(right) of a microscope image capture of the same wire(left).

Figure 4. Microscope image (left) of part compared acquired scanned surface profile(right)

IX. CONCLUSSION

The developed system was used successfully for the analysis and quality control of prestressing steel

reinforcement wire geometry[5]. The non-contact profiling system was able to identify critical geometrical

features and their influence on reinforcement wire performance in concrete members[6,7]. The designed system

maintains a sub-micron resolution and state of the art sampling rates while being at a fraction of the cost of

commercially available systems. Additionally, the developed software allows for autonomous geometrical

feature measurements making autonomous 100% inspection of geometrical measurements practical for

industrial applications. System limitations consist of the mechanical hardware and the specialization

requirements for the autonomous geometrical feature measurements. The mechanical hardware is part specific](https://image.slidesharecdn.com/c0321519-131004235346-phpapp01/75/Design-of-a-Non-Contact-Surface-Profilometry-System-for-Automated-Geometrical-Dimensioning-and-Tolerancing-4-2048.jpg)

![Design of a Non-Contact Surface Profilometry System for Automated Geometrical Dimensioning

www.ijeijournal.com Page | 19

and performing automated surface profiling on different part geometries will require a different hardware

arrangement. Each geometrical feature measurement extracted by the software requires specialized software

development to achieve robust feature extraction.

ACKNOWLEDGEMENTS

The authors would like to thank the Federal Railroad Administration (FRA) for providing the majority

of the funding that made this research possible. Additionally, LB Foster/CXT Concrete Ties has donated

extensive resources, including all of the reinforcements, to make the project a success. The researchers would

also like to thank Drs. Hailing Yu and David Jeong at the John A. Volpe National Transportation Systems

Center for their valuable suggestions and parallel analysis work. Finally, the authors wish to thank the

Precast/Prestressed Concrete Institute (PCI) for establishing an industry advisory panel to the project, the

Kansas State University’s University Transportation Center (K-State UTC) for graduate student tuition support,

and the Advanced Manufacturing Institute (AMI) for manufacturing services.

REFERENCES

[1] Mark D. Haynes. “3D Non-Contact Profilometry for Reinforcement Steel Quality Control”. Industrial and Systems Engineering

Research Conference, May (2013)

[2] Mark D. Haynes, Chih-Hang Wu, Terry B. Beck, et al., "Automated real-time search and analysis algorithms for a non-contact 3D

profiling system", Proceedings of SPIE Vol. 8791, 87911G (2013)

[3] Umesh Arasu and John Wu, (1997) “Geometric Tolerance Verification Algorithms for Computer Vision Inspection.” Kansas State

University.

[4] ASTM International, 2010 Standard Specification for Steel Wire, Indented, Low-Relaxation for Prestressed Concrete Railroad Ties,

Designation: A881/A881M (2010)

[5] Mark D. Haynes. “Pre-Stressing Steel Reinforcement Wire Bond Index Number”. Joint Rail Conference, April 2013

[6] Weixin Zhao, “An Automated Transfer Length Measurement System for Use on Concrete Railroad Ties” Prestressed Concrete

Institute National Bridge Conference (2012)

[7] Naga Narendra B. Bodapati. “Influence of Indented Wire Geometry and Concrete Parameters on the Transfer Length in Prestressed

Concrete Crossties.” Joint Rail Conference, April (2013)](https://image.slidesharecdn.com/c0321519-131004235346-phpapp01/75/Design-of-a-Non-Contact-Surface-Profilometry-System-for-Automated-Geometrical-Dimensioning-and-Tolerancing-5-2048.jpg)