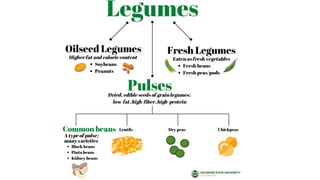

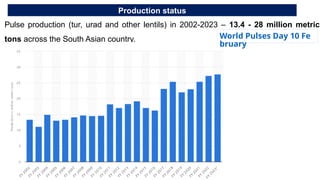

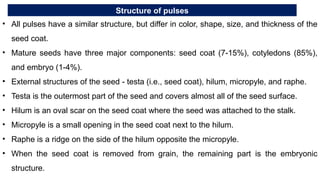

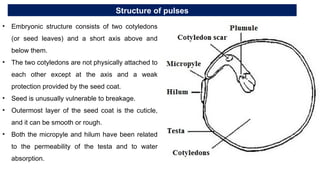

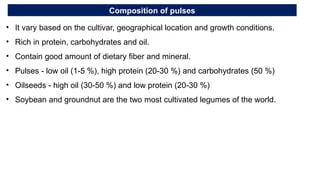

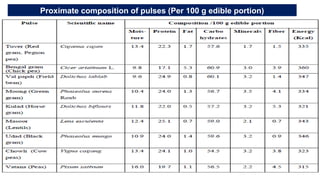

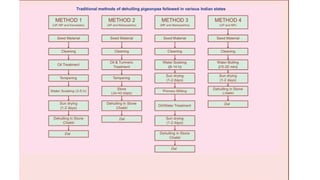

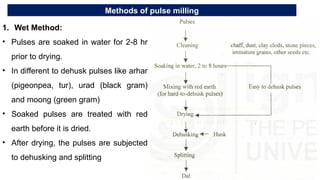

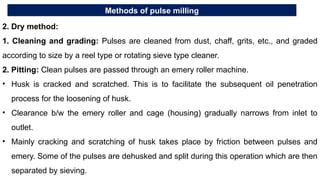

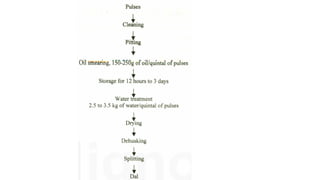

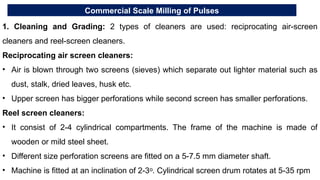

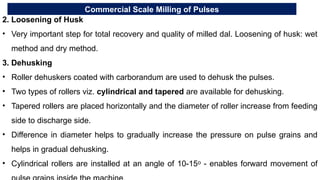

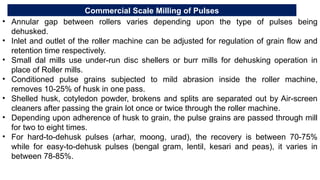

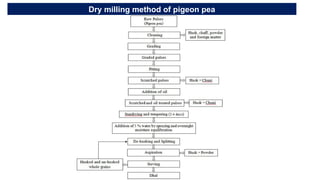

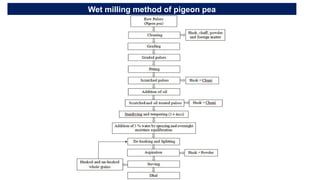

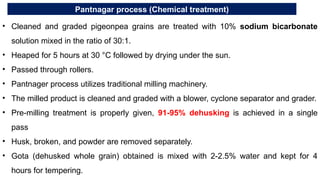

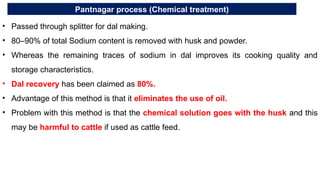

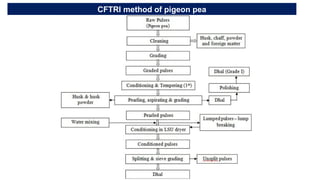

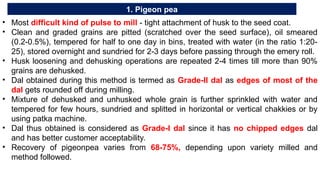

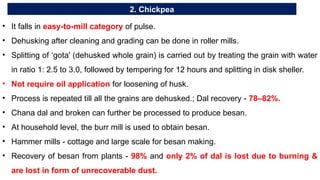

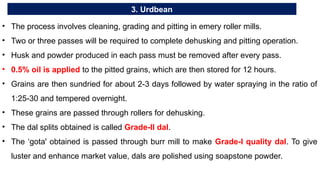

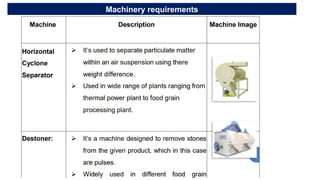

The document provides an extensive overview of legumes and pulses, covering their classification, nutritional composition, and production status. It details the structural components of pulses, their health benefits, antinutritional factors, and the methodologies involved in pulse milling across different scales. Additionally, it discusses the advancements in milling technology aimed at improving efficiency and reducing waste.