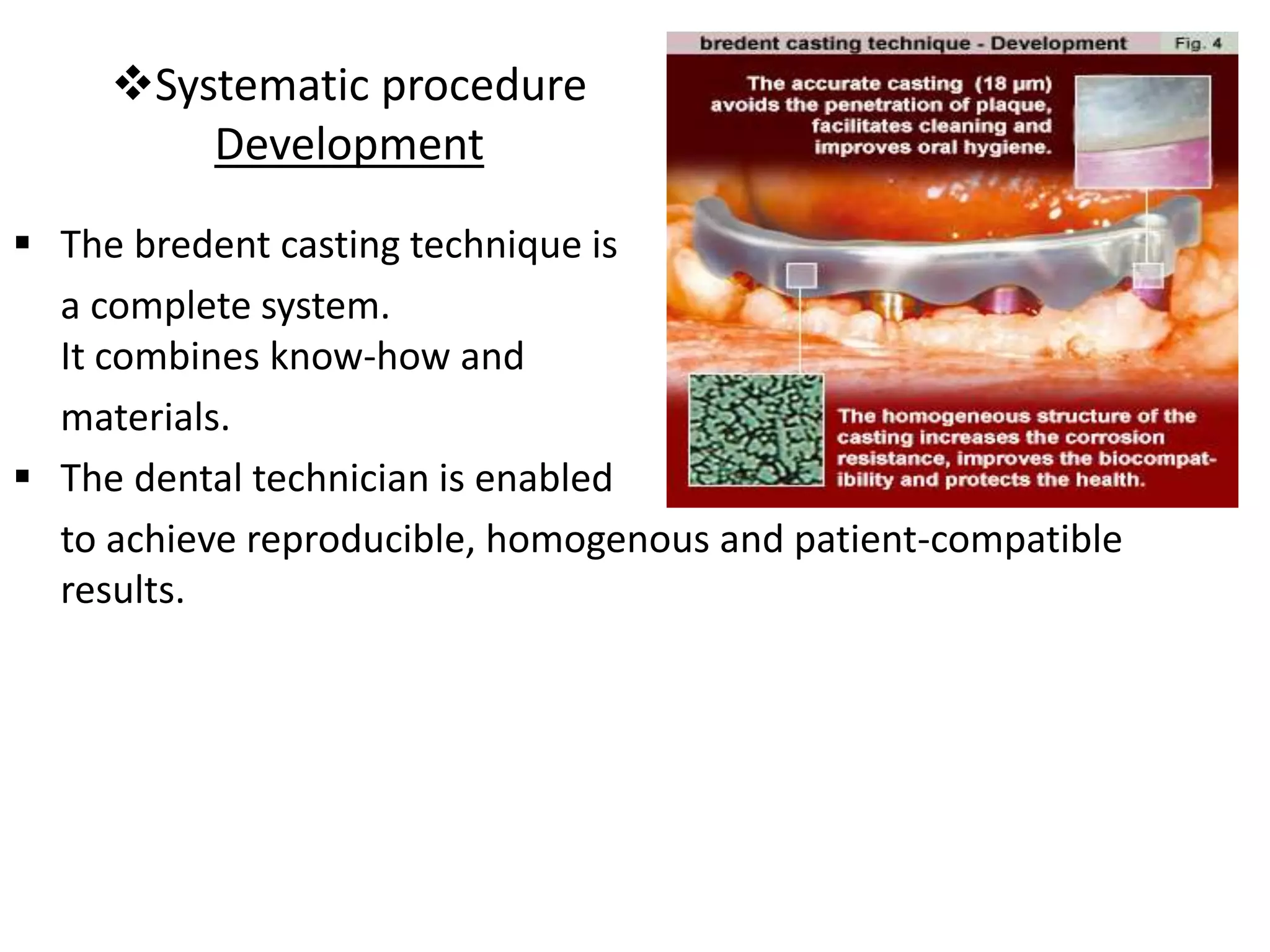

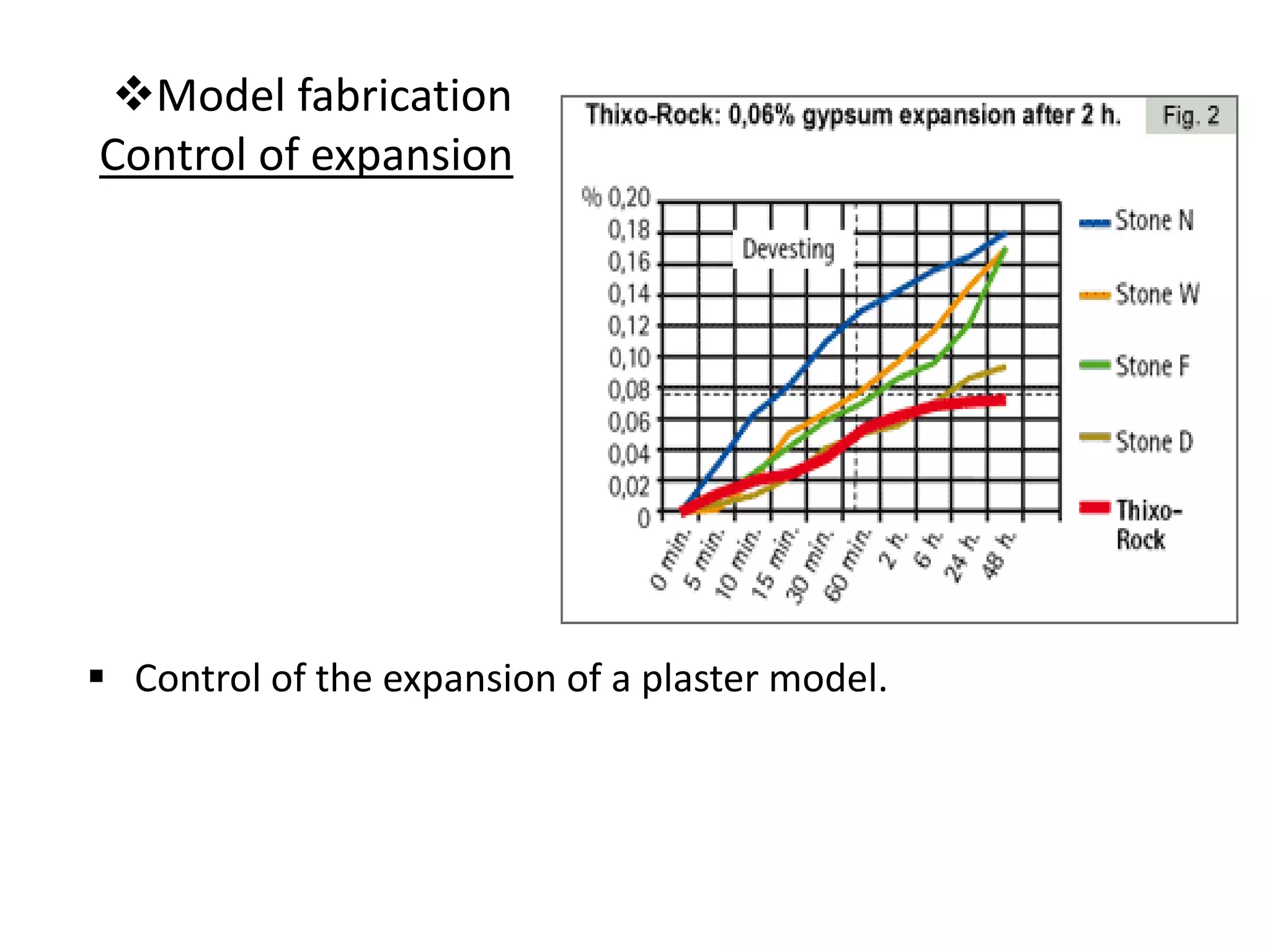

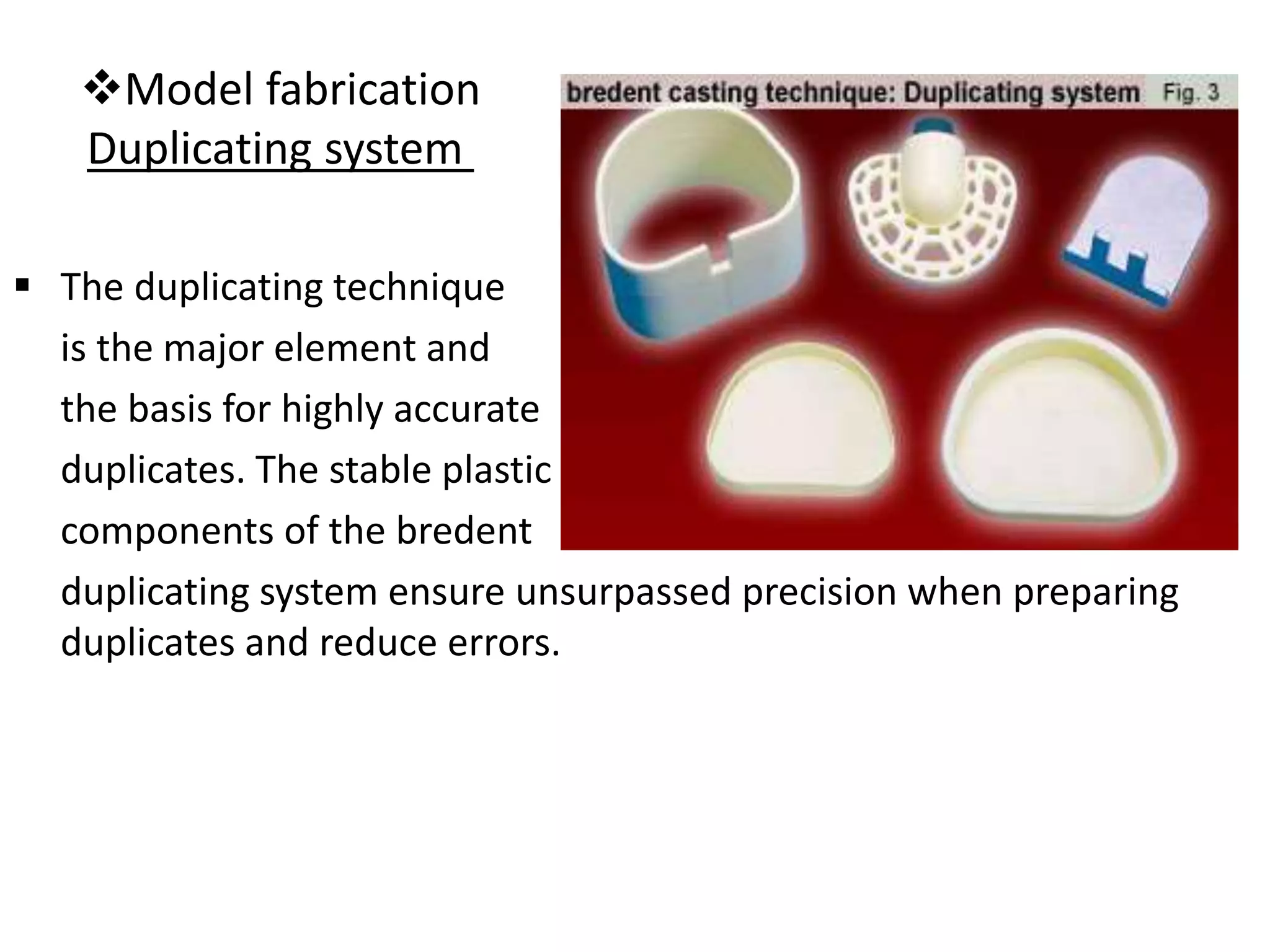

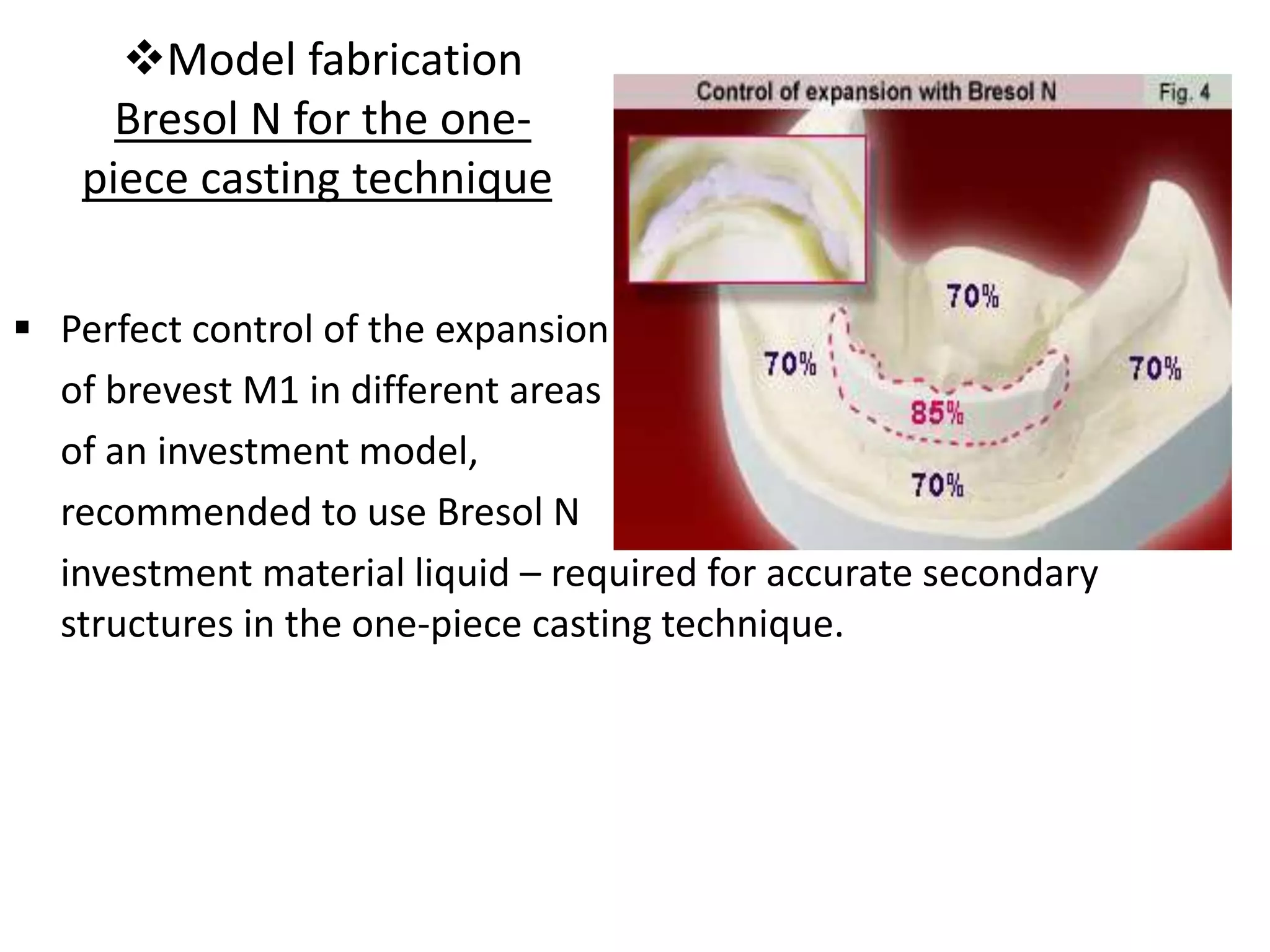

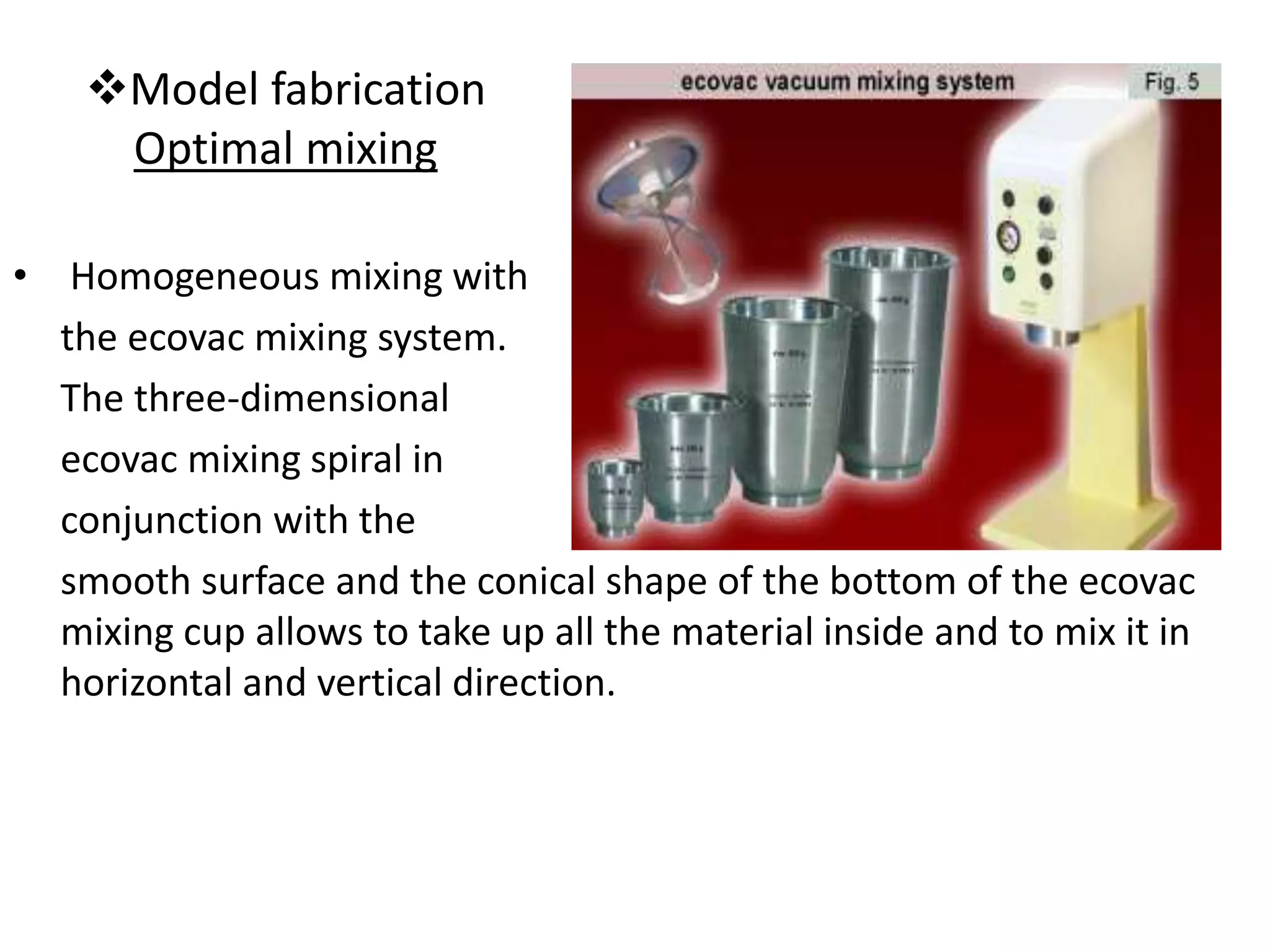

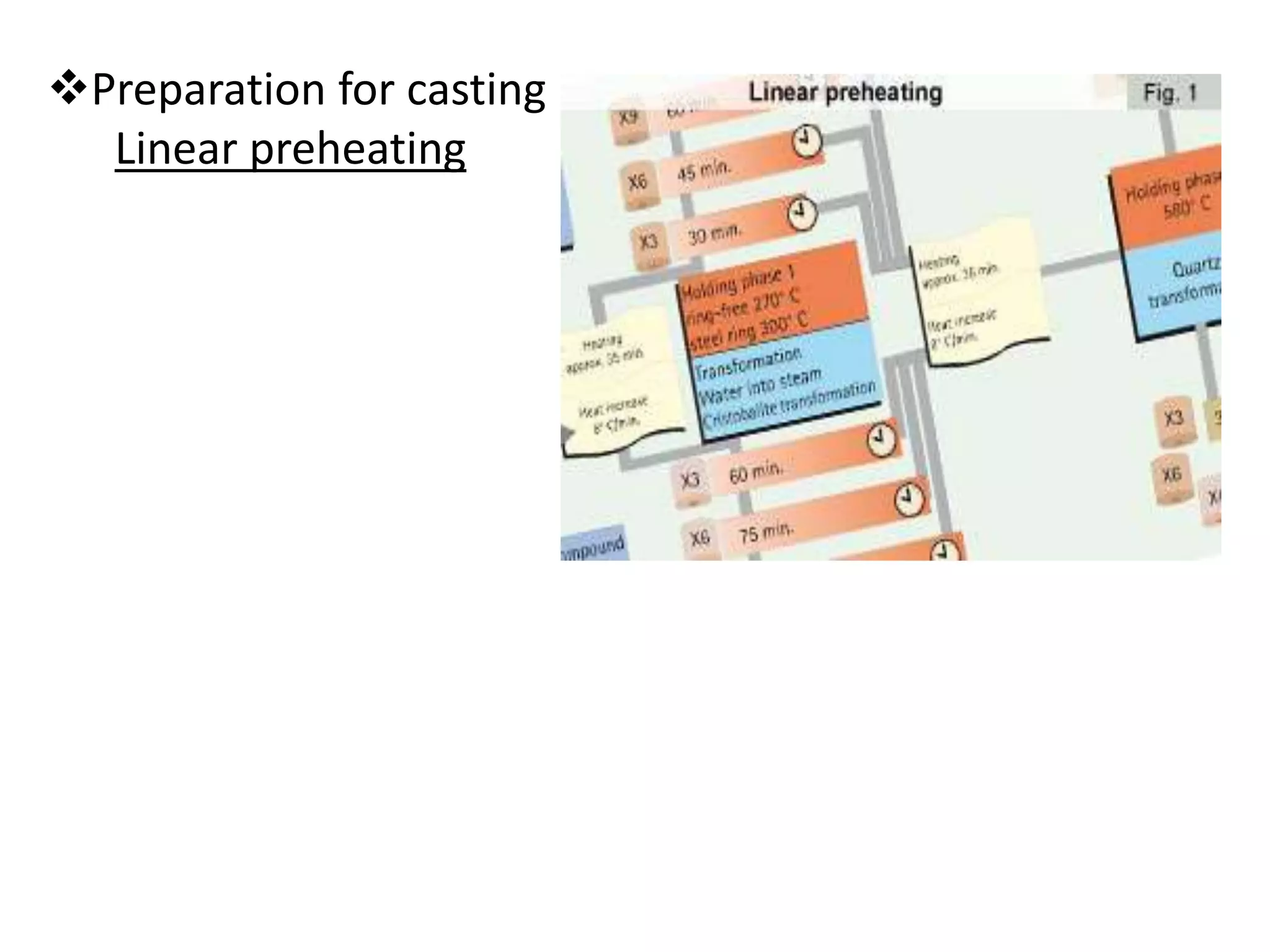

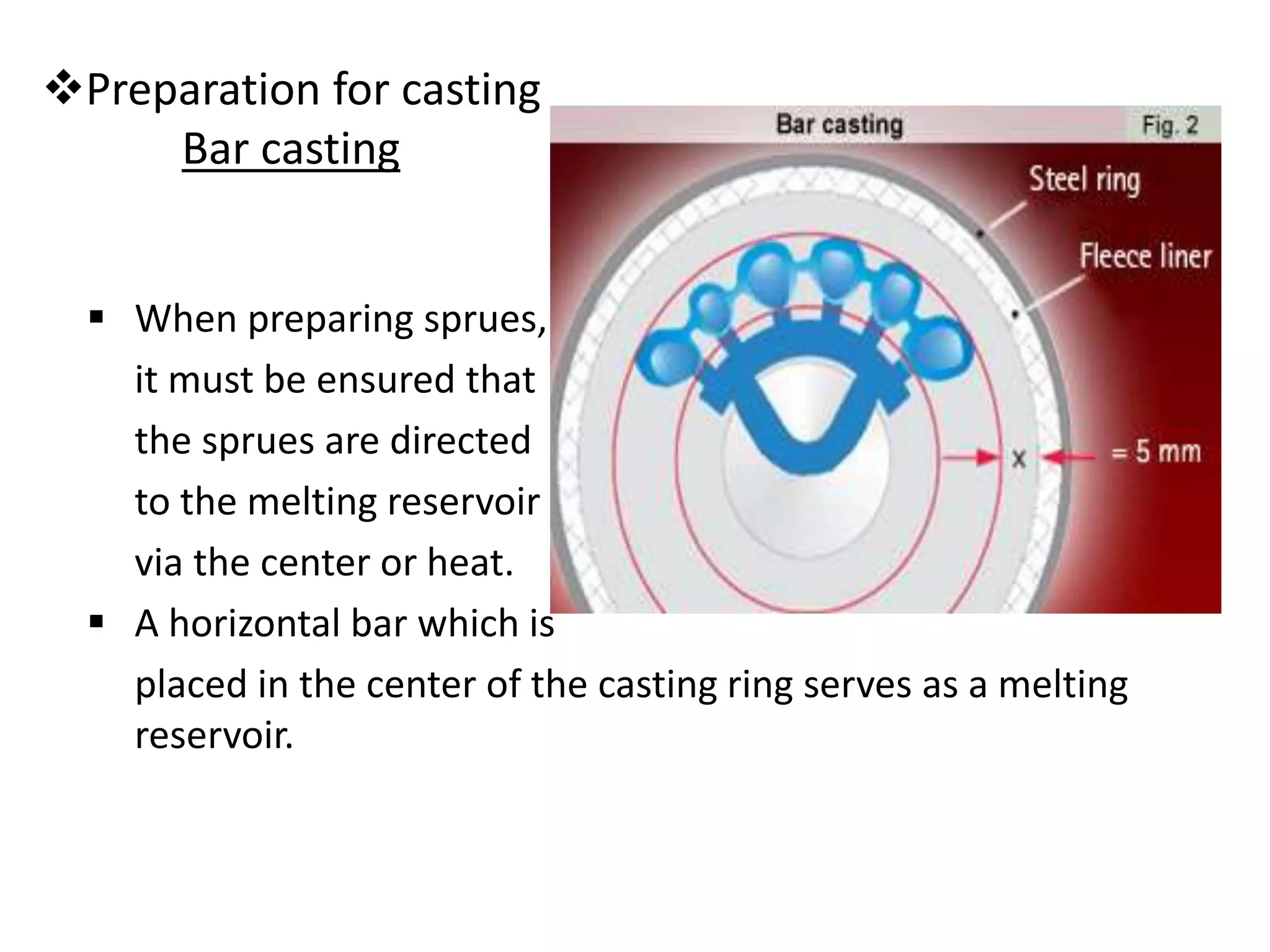

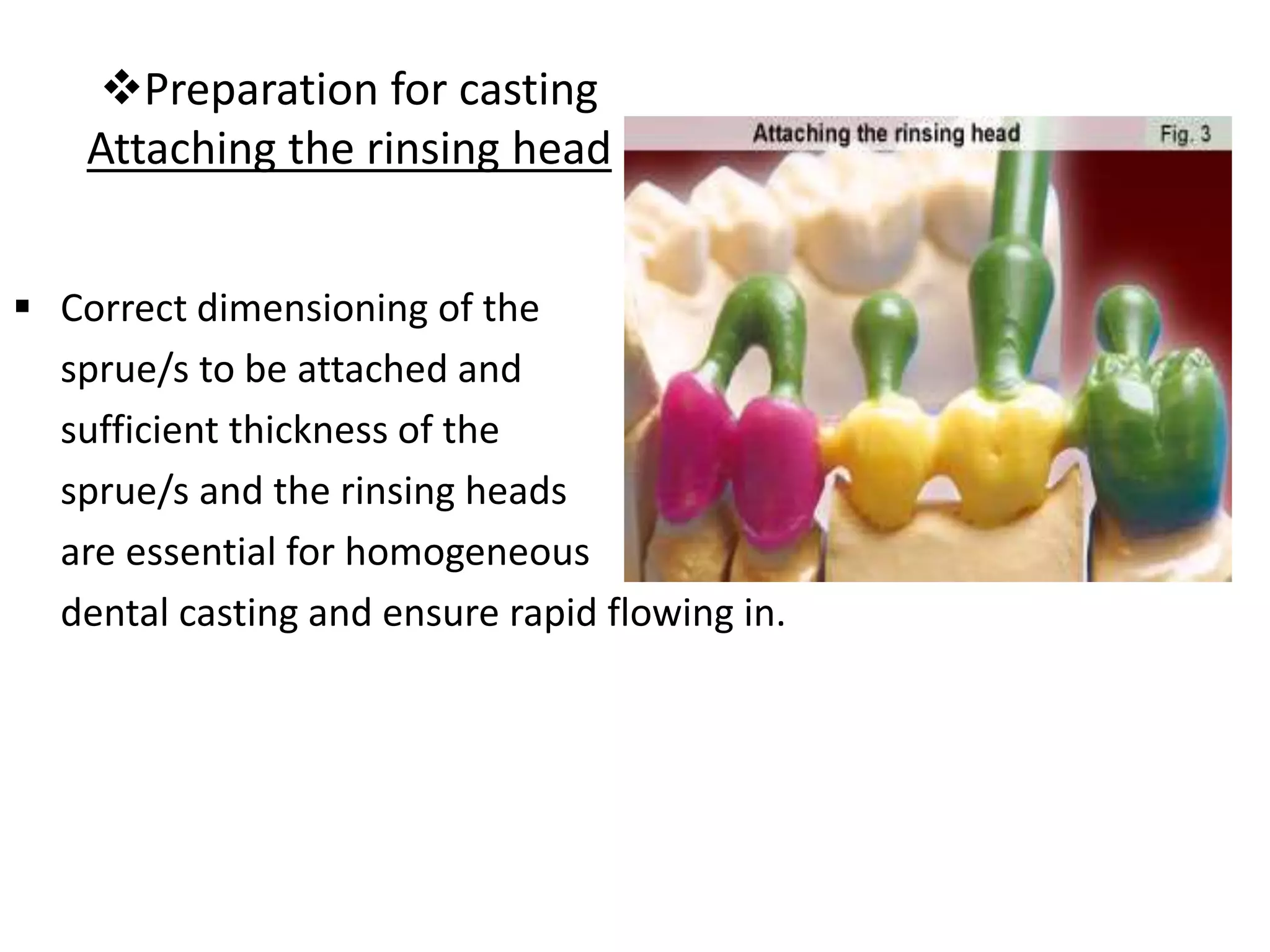

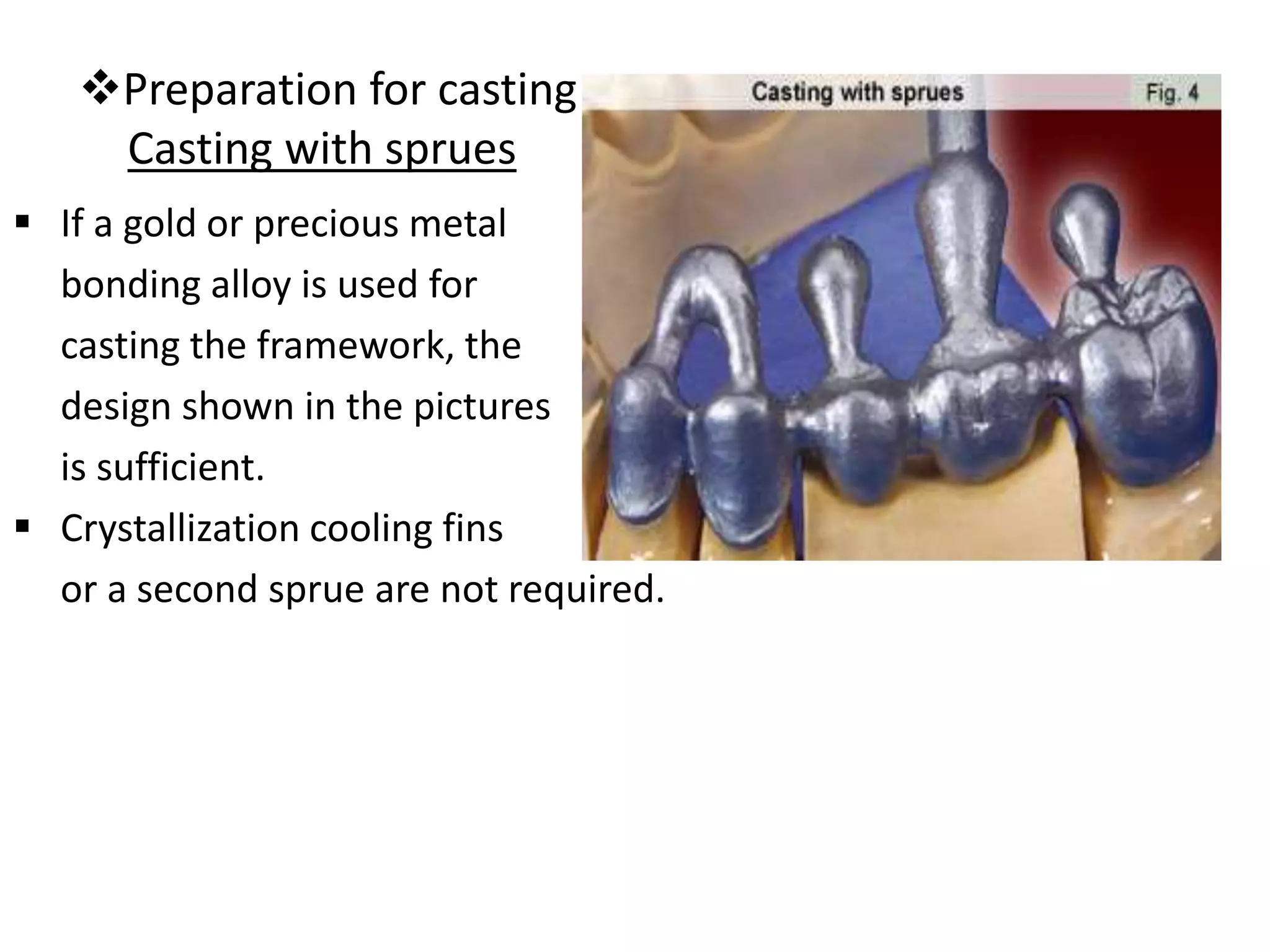

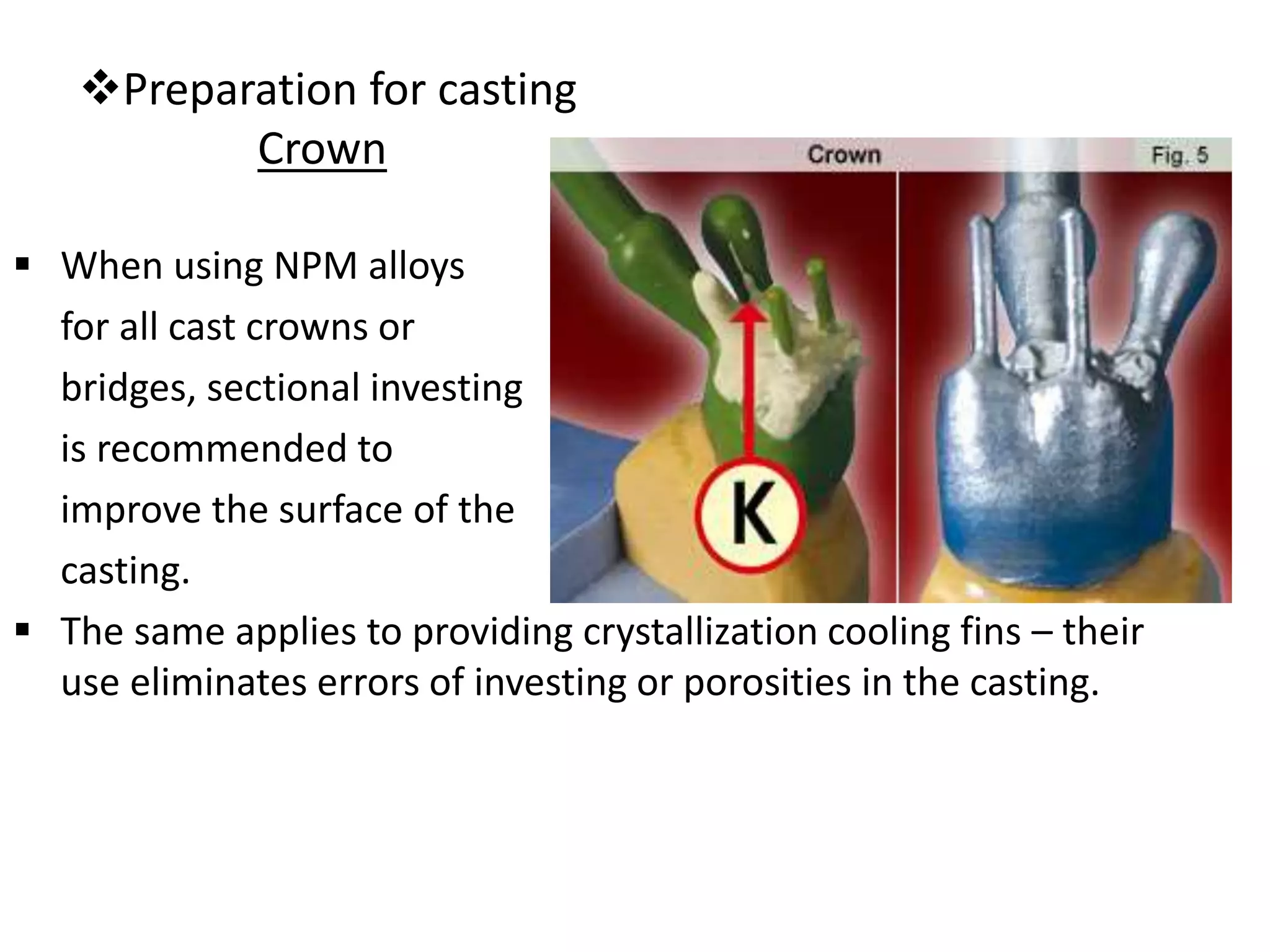

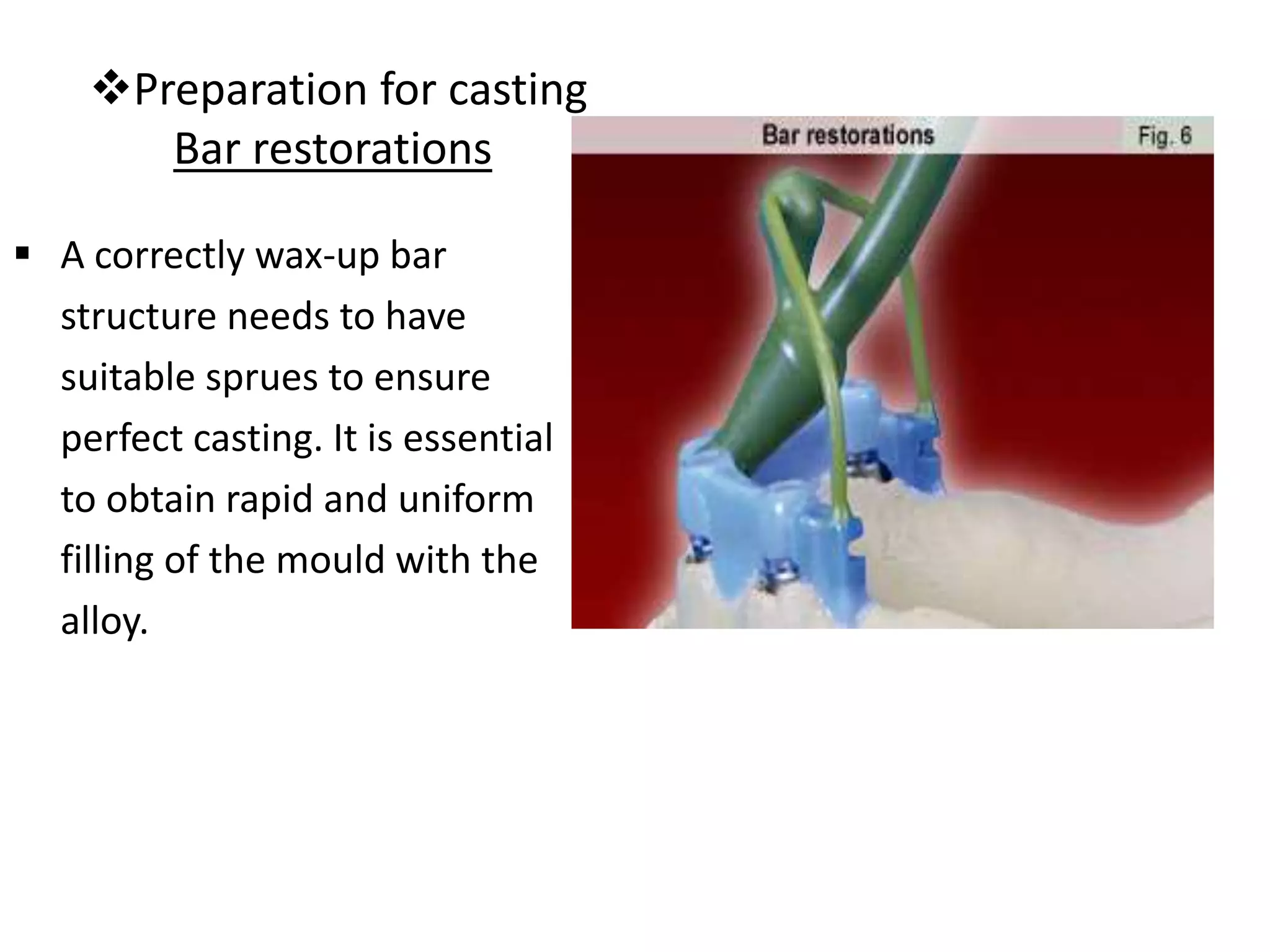

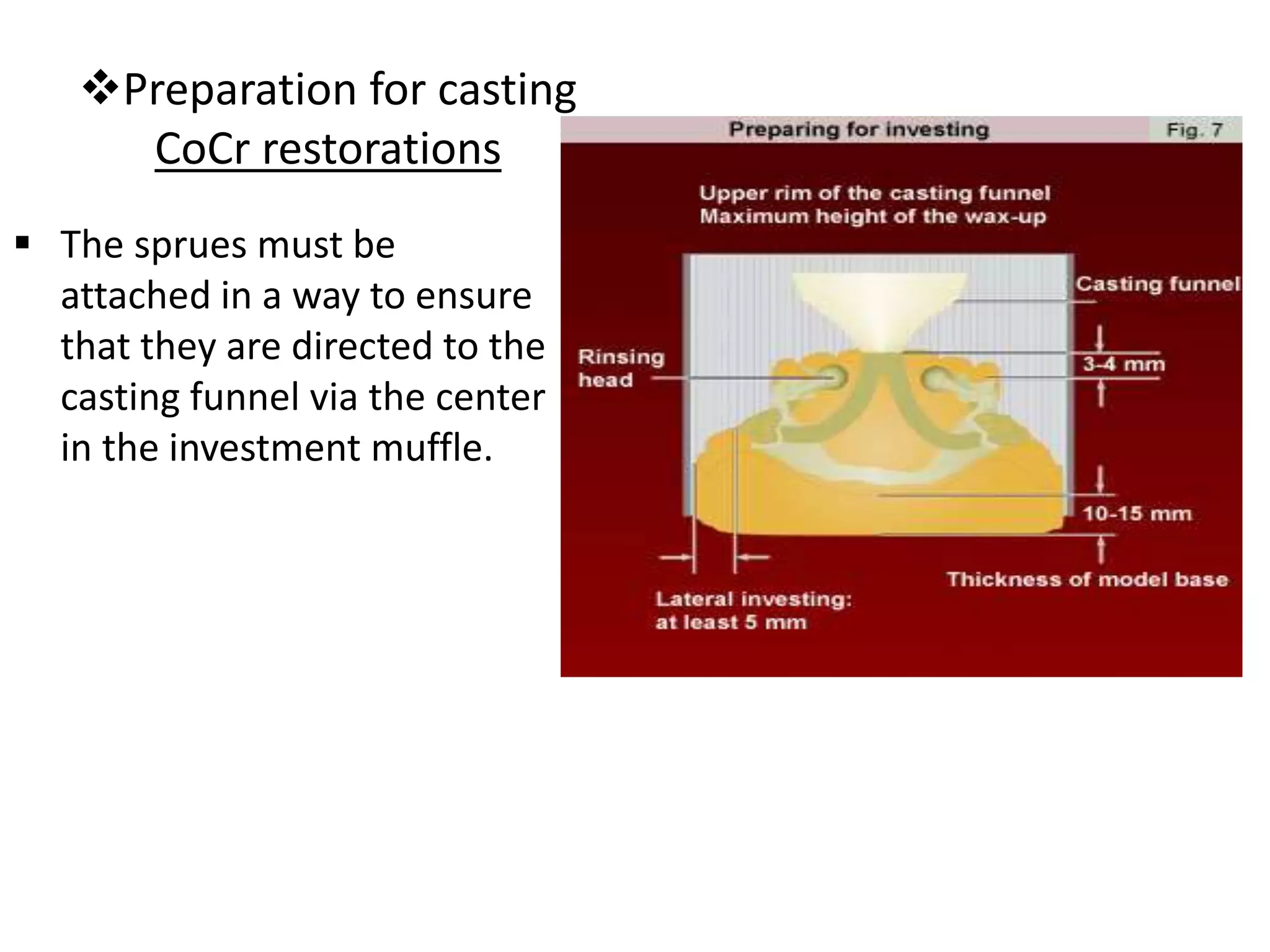

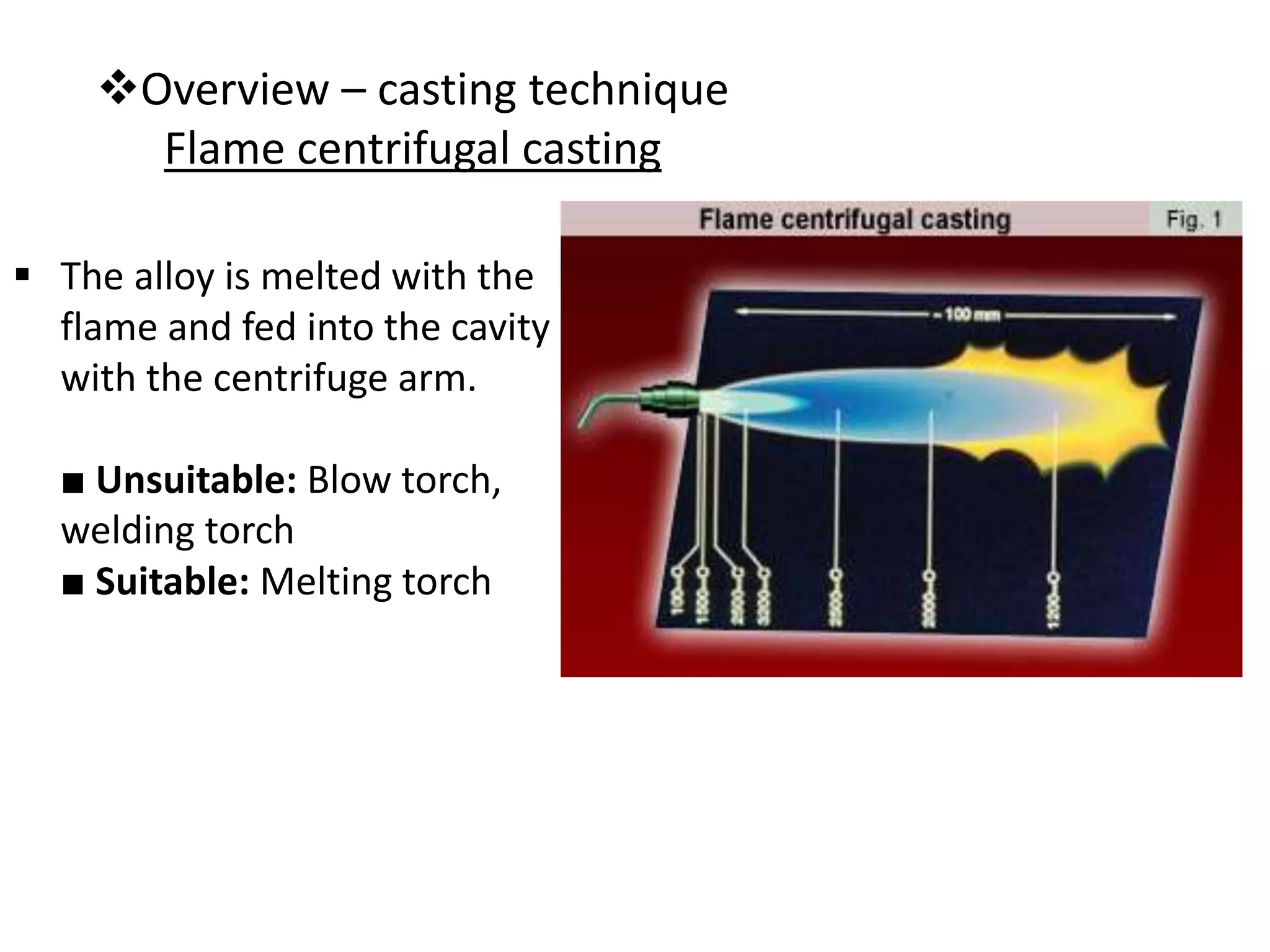

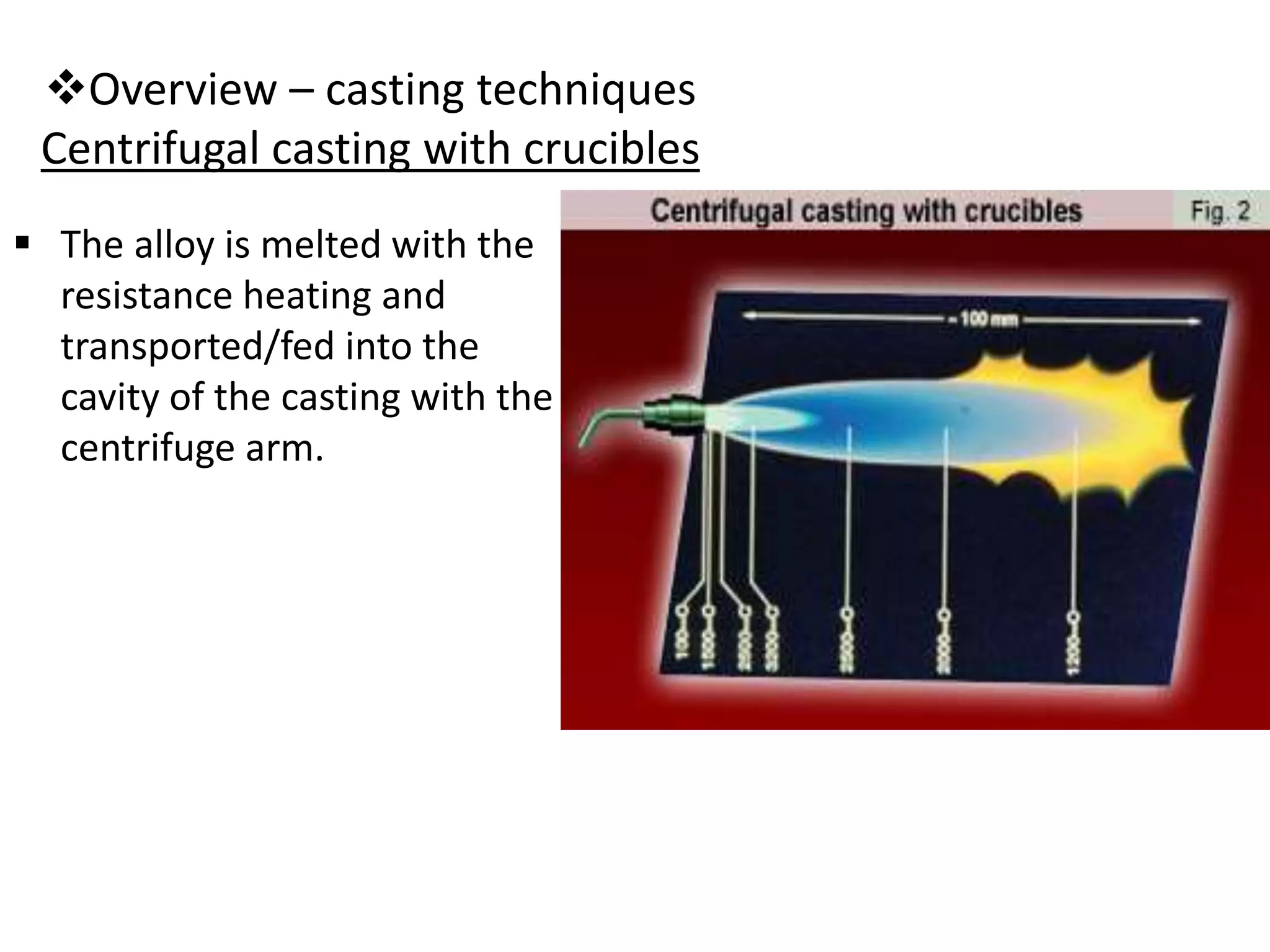

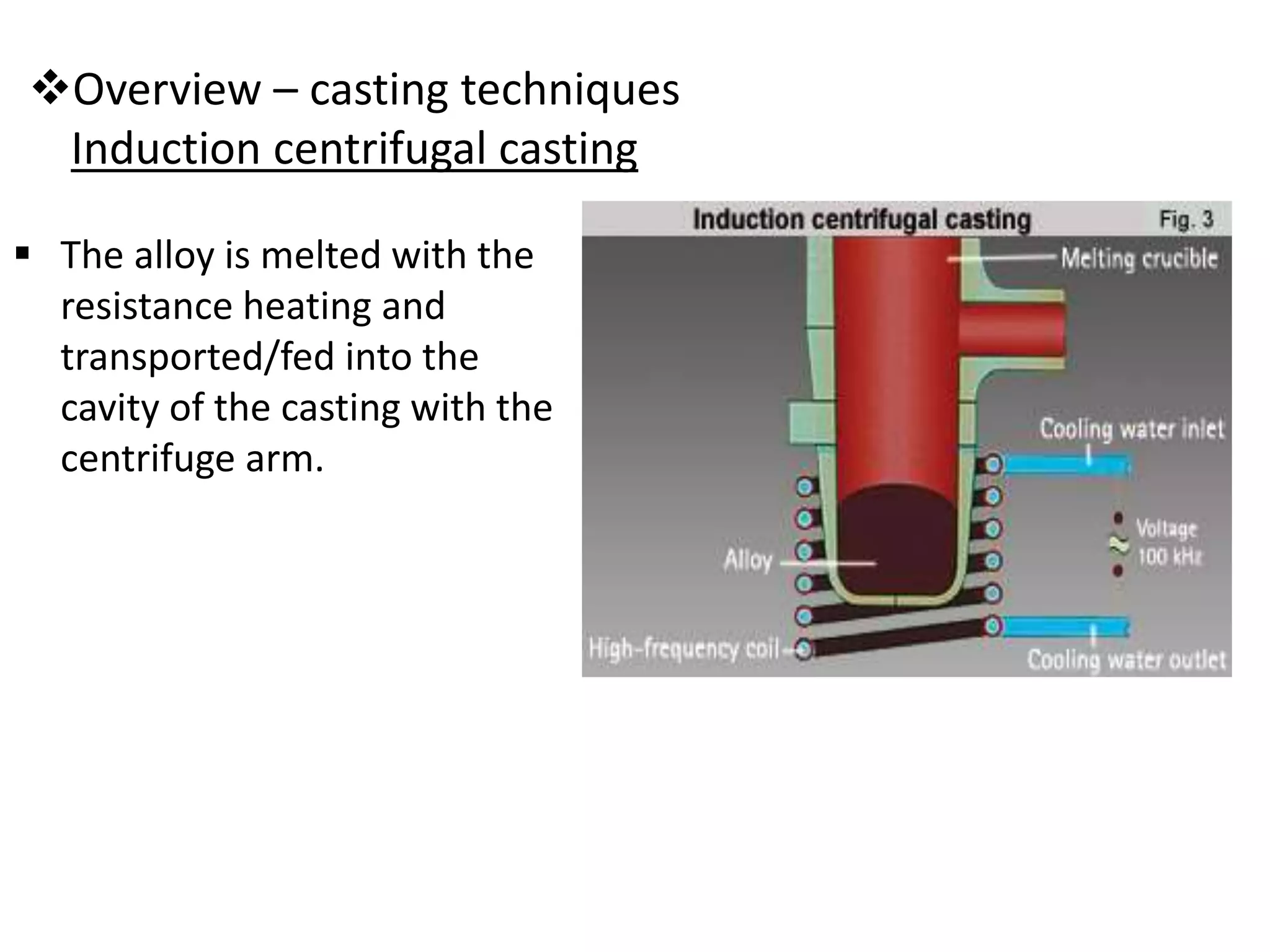

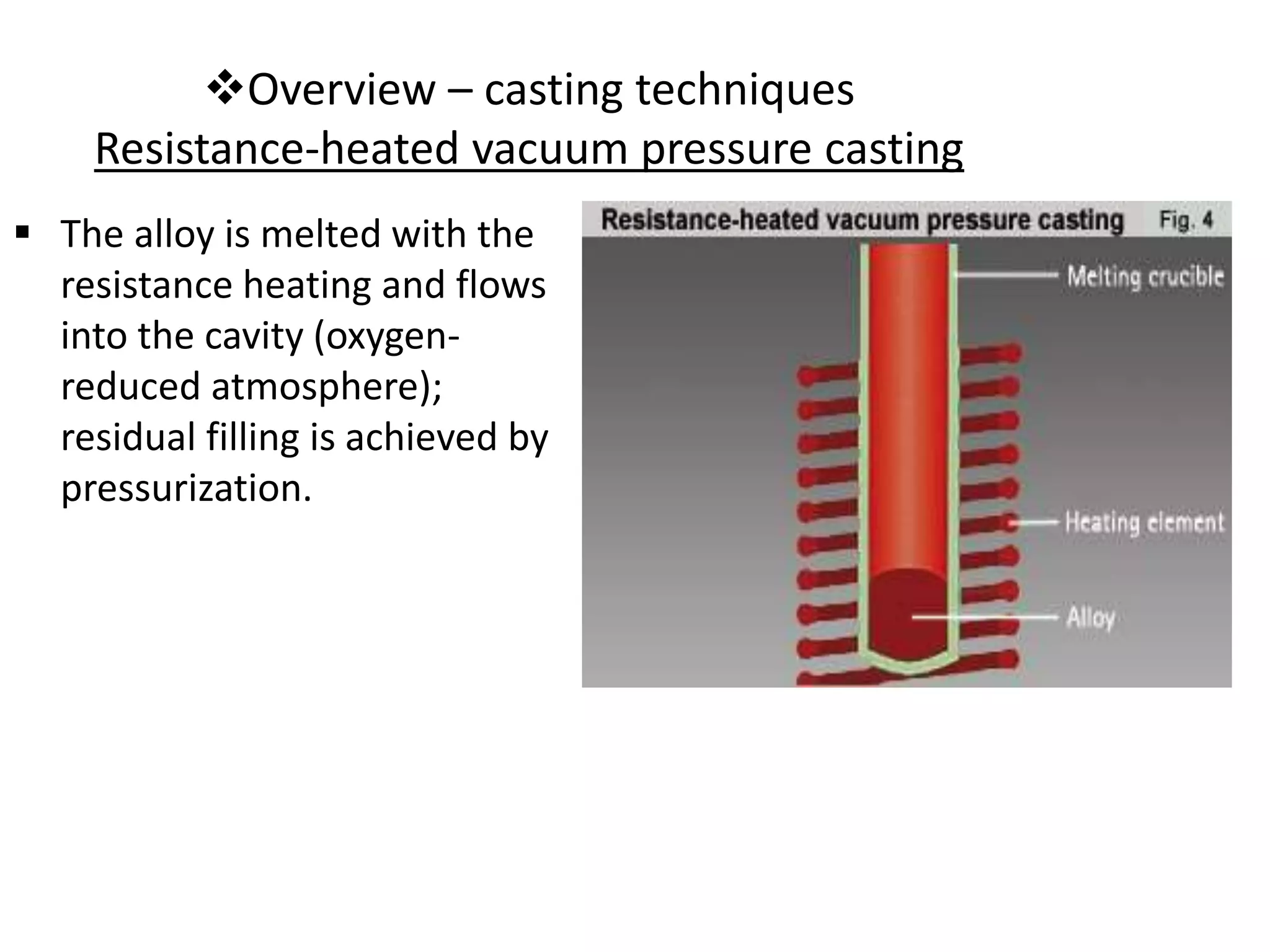

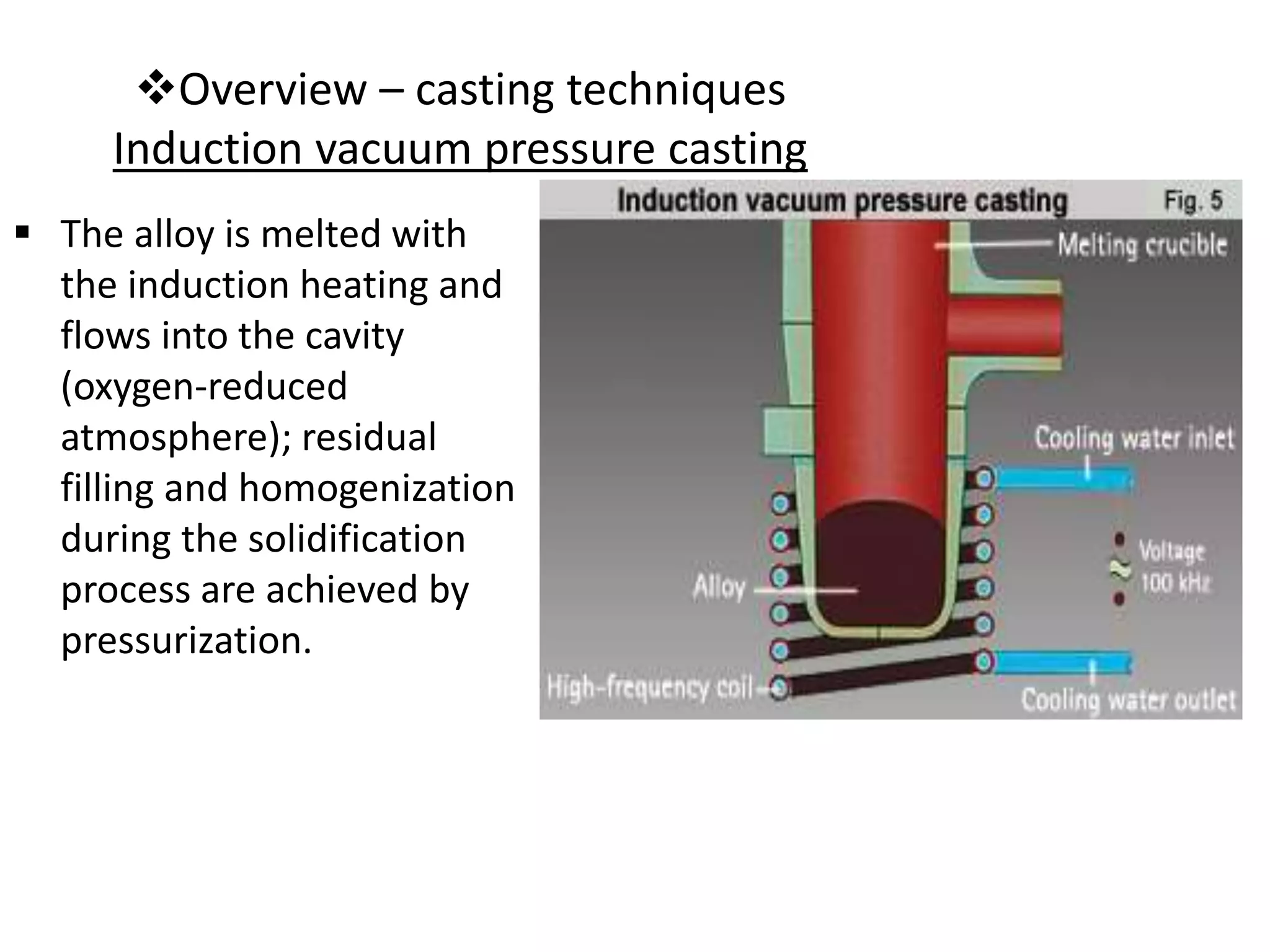

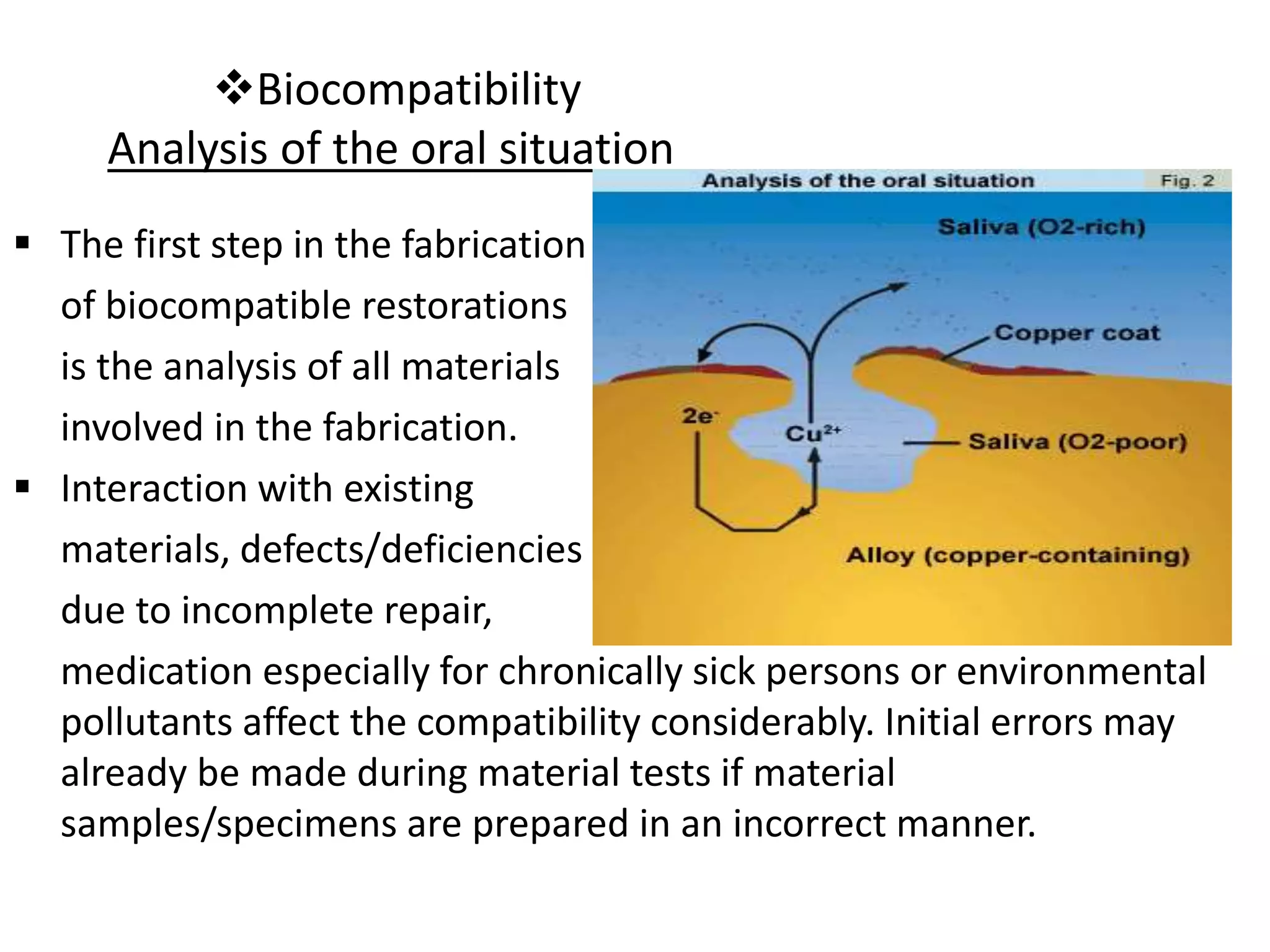

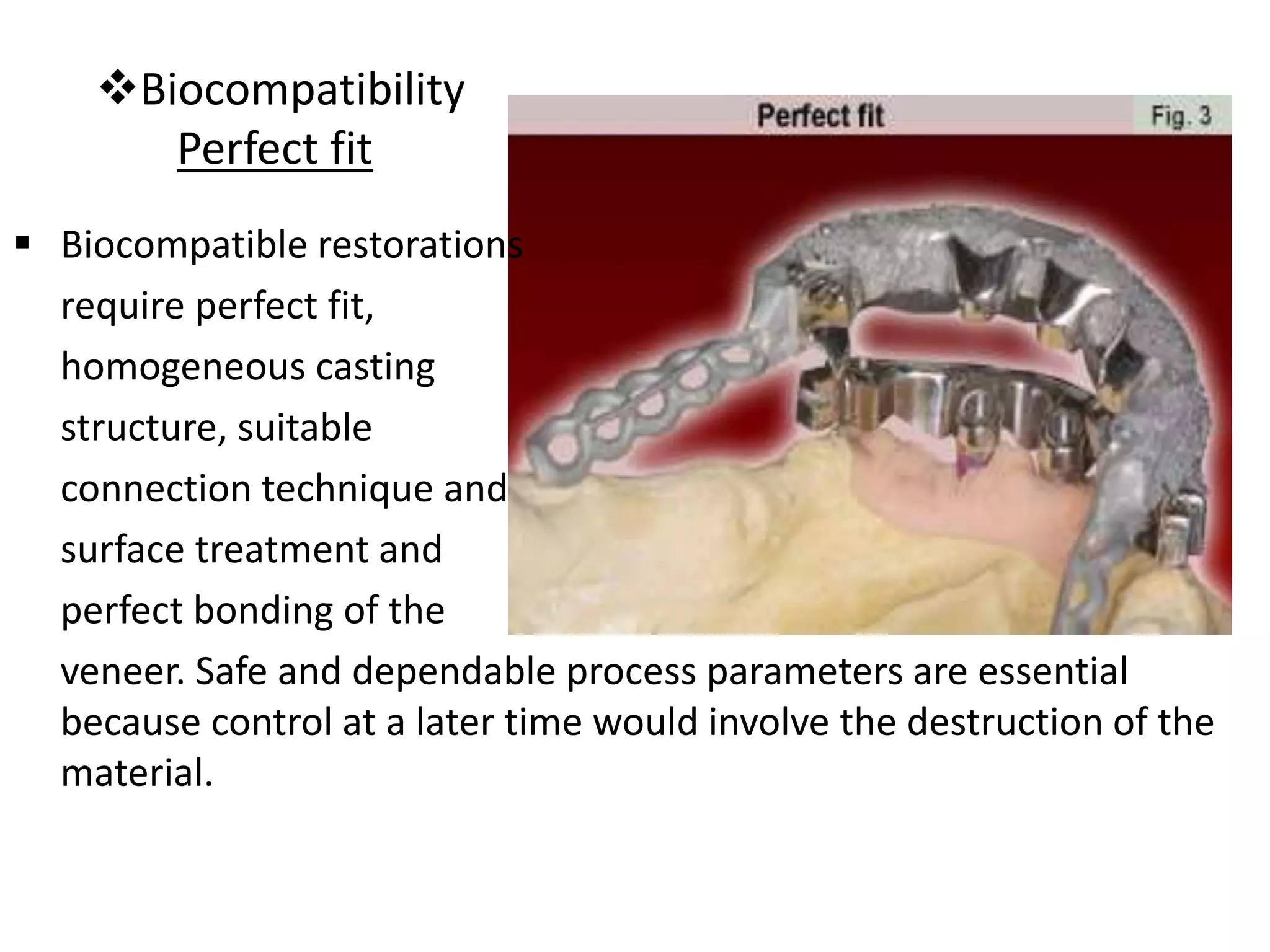

The document discusses the Bredent Casting Technique, which includes a systematic procedure for producing dental casts and restorations using specific materials and processes. It involves careful planning, model fabrication using stones and duplicating systems, preparation for casting including attaching sprues, and an overview of casting techniques. The technique aims to produce high-quality, biocompatible restorations through thorough planning, a perfect fit, homogeneous casting structure, and proper surface treatment.