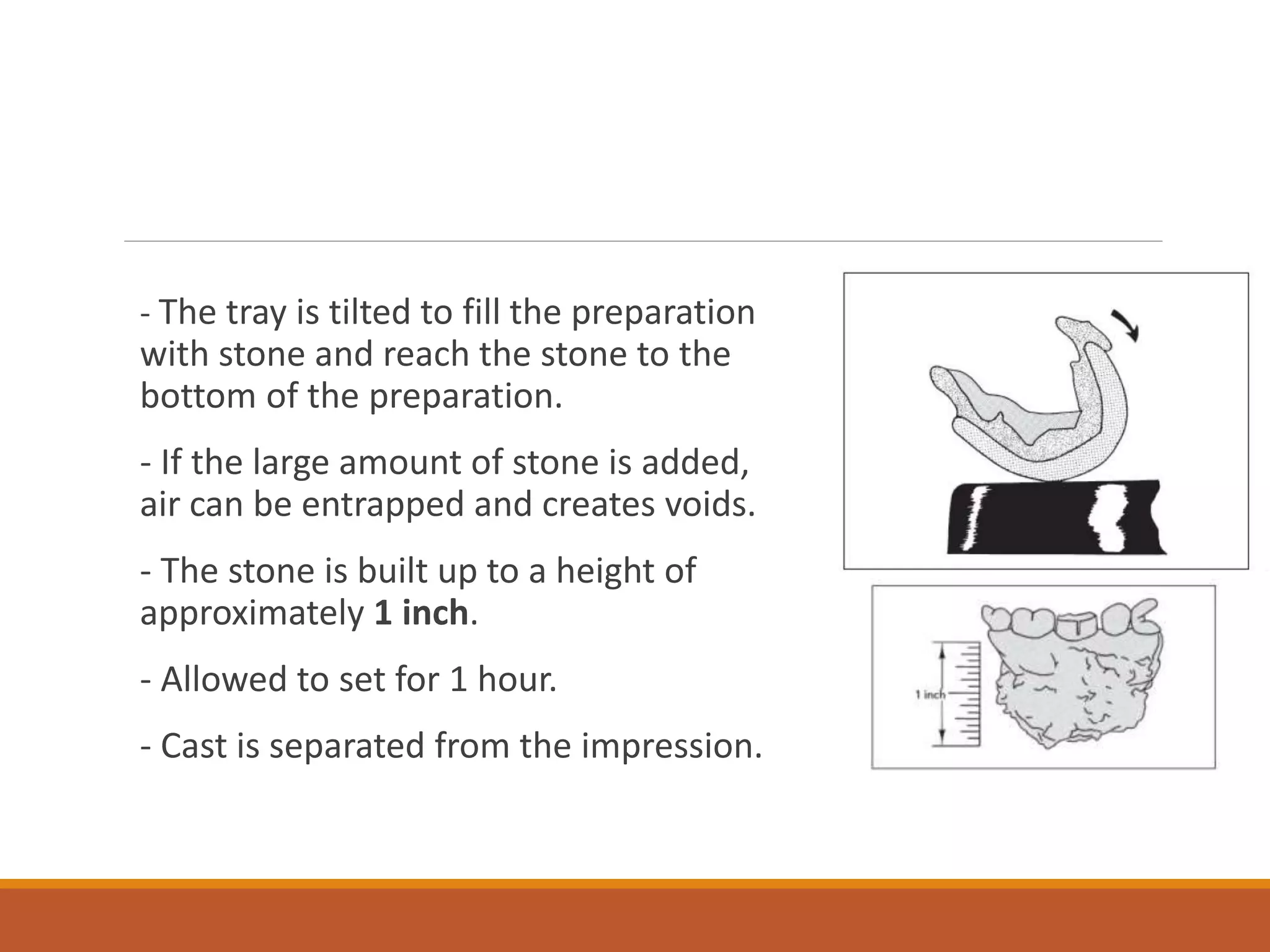

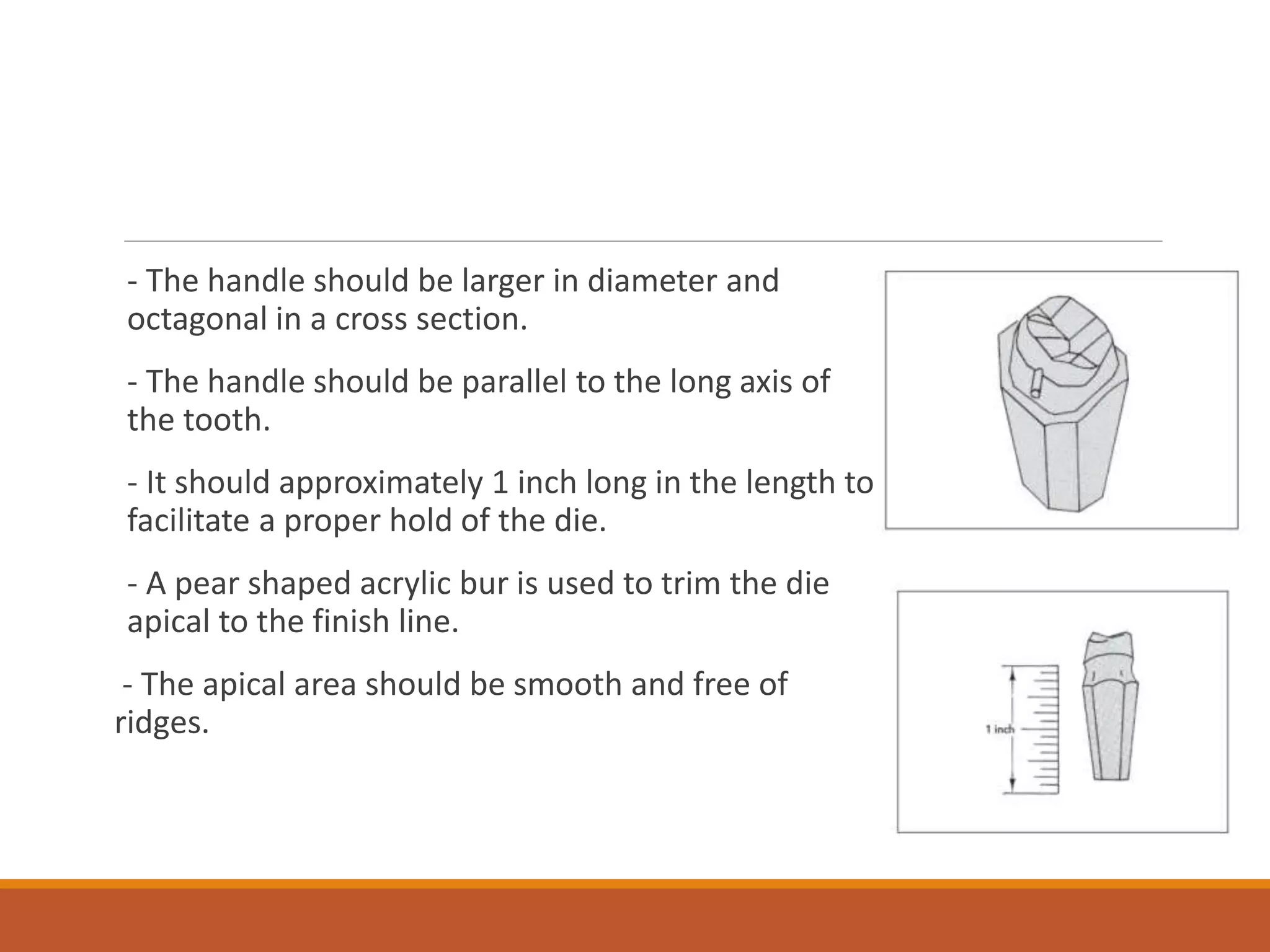

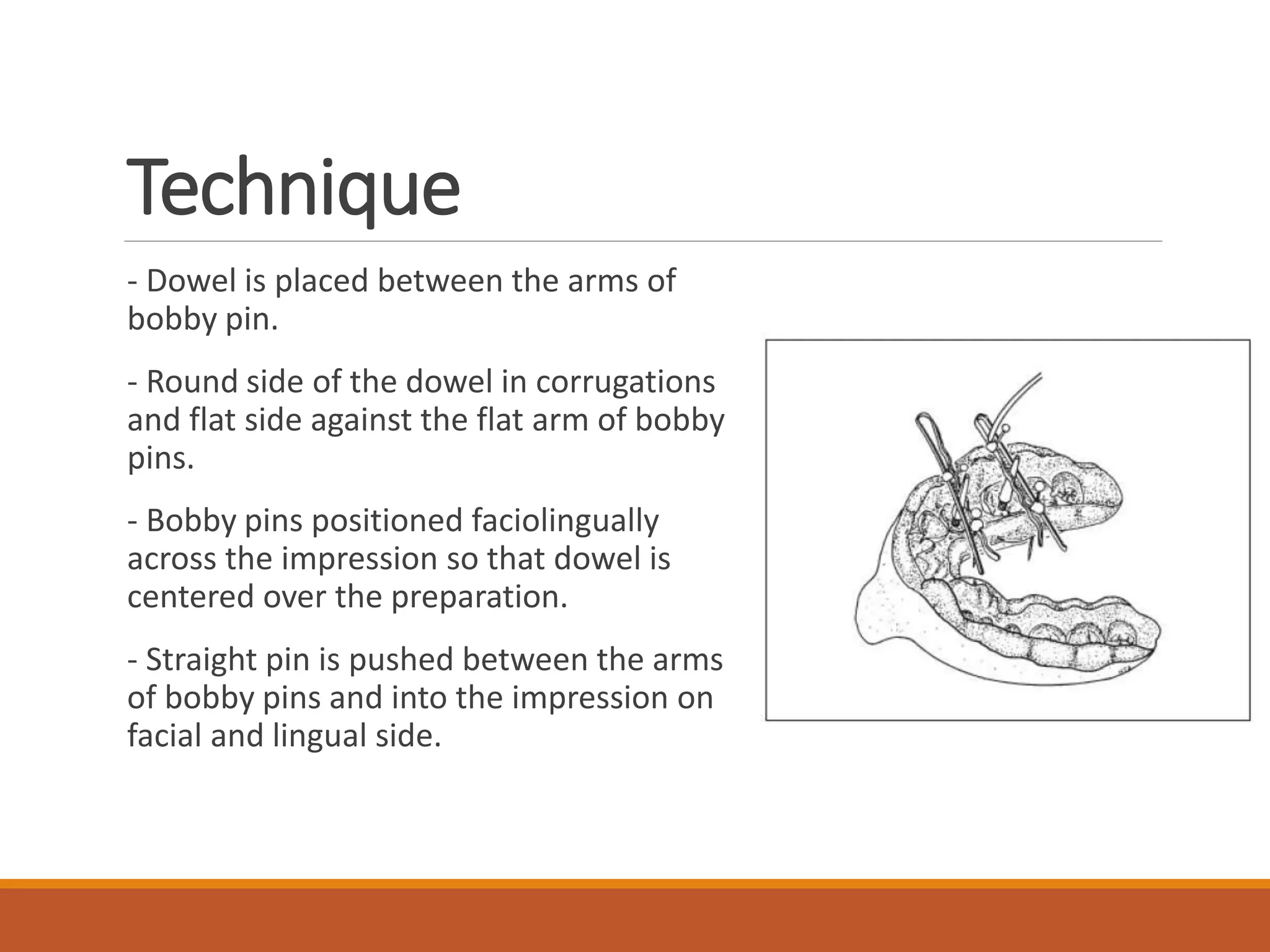

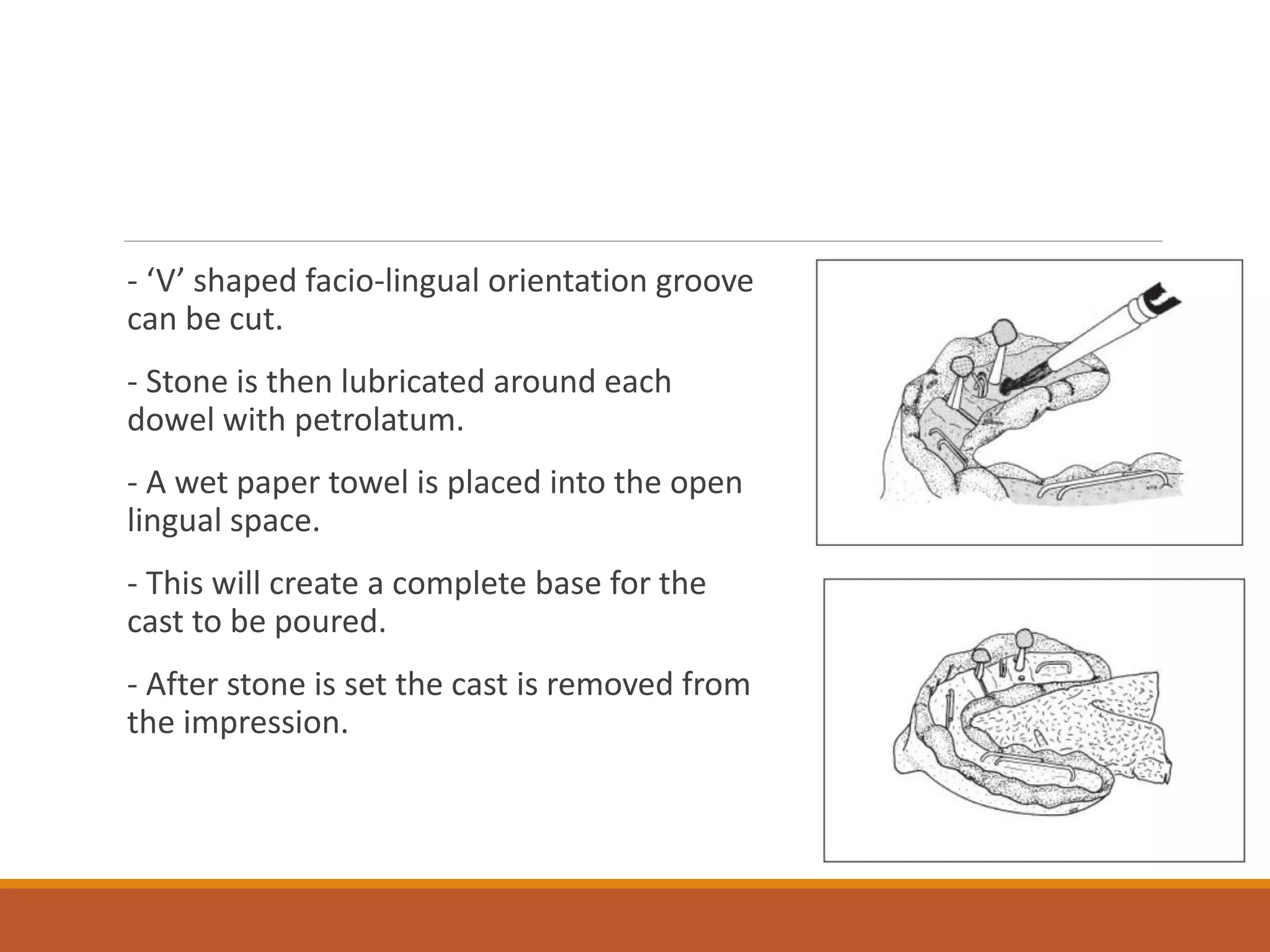

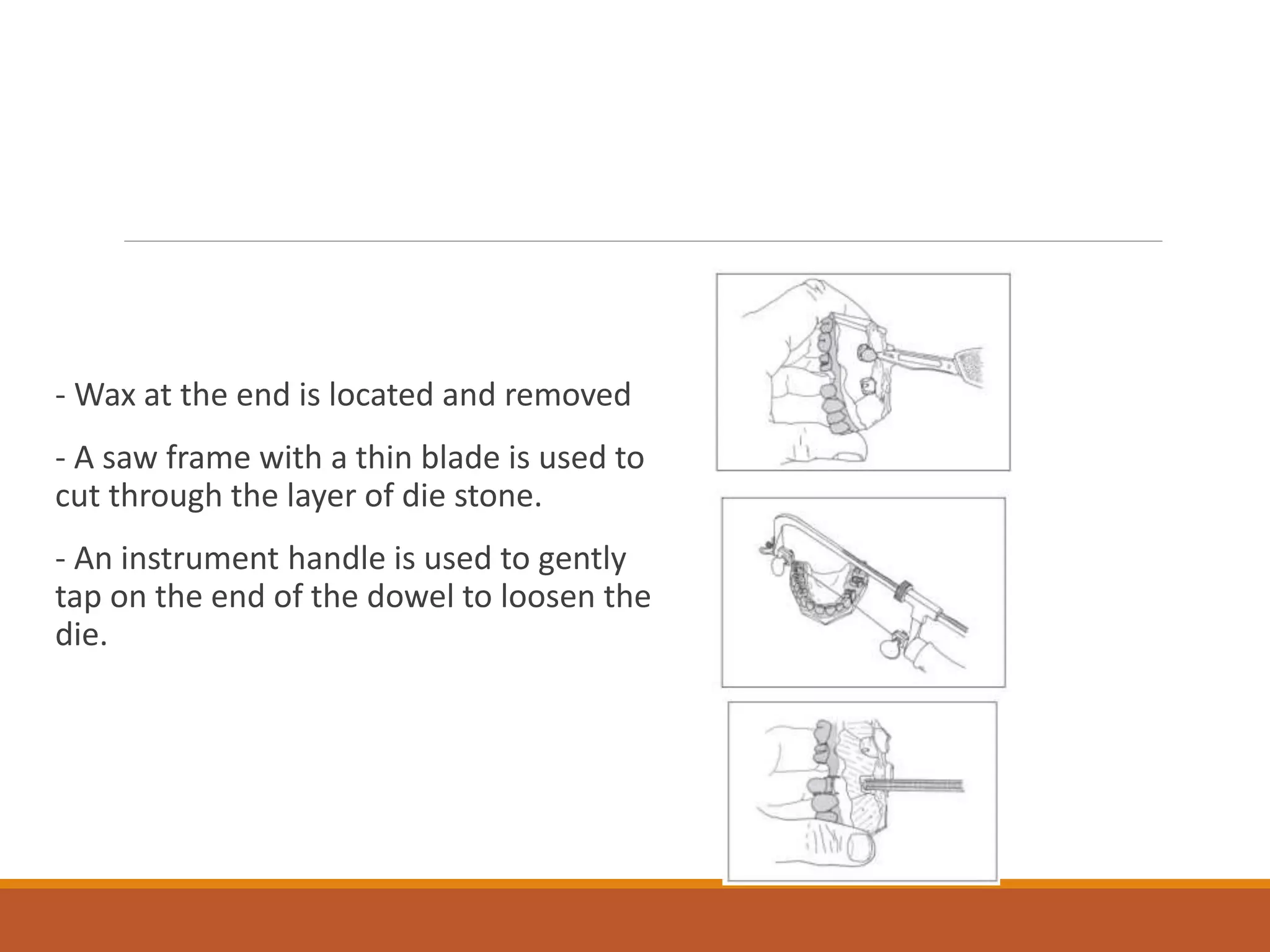

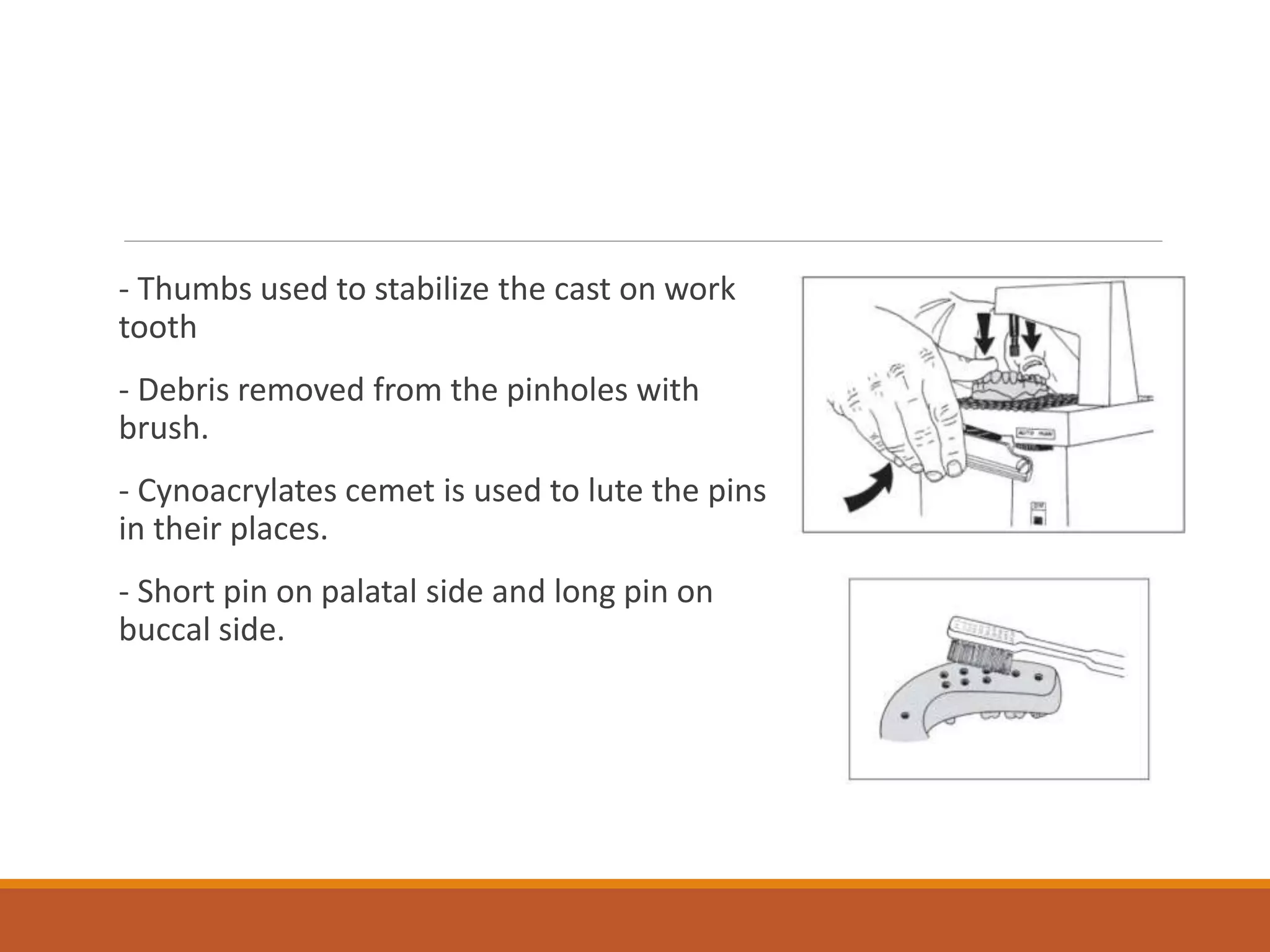

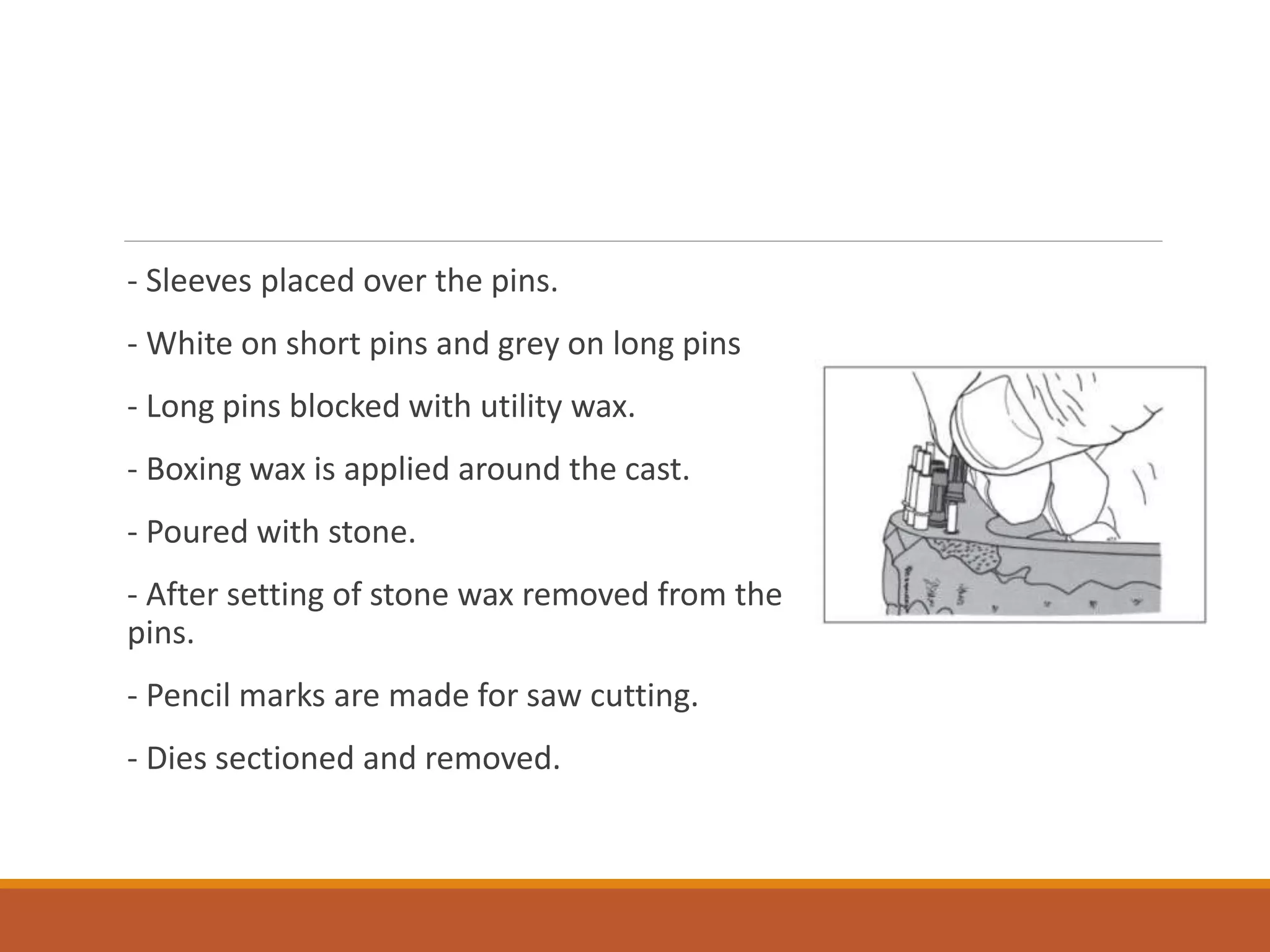

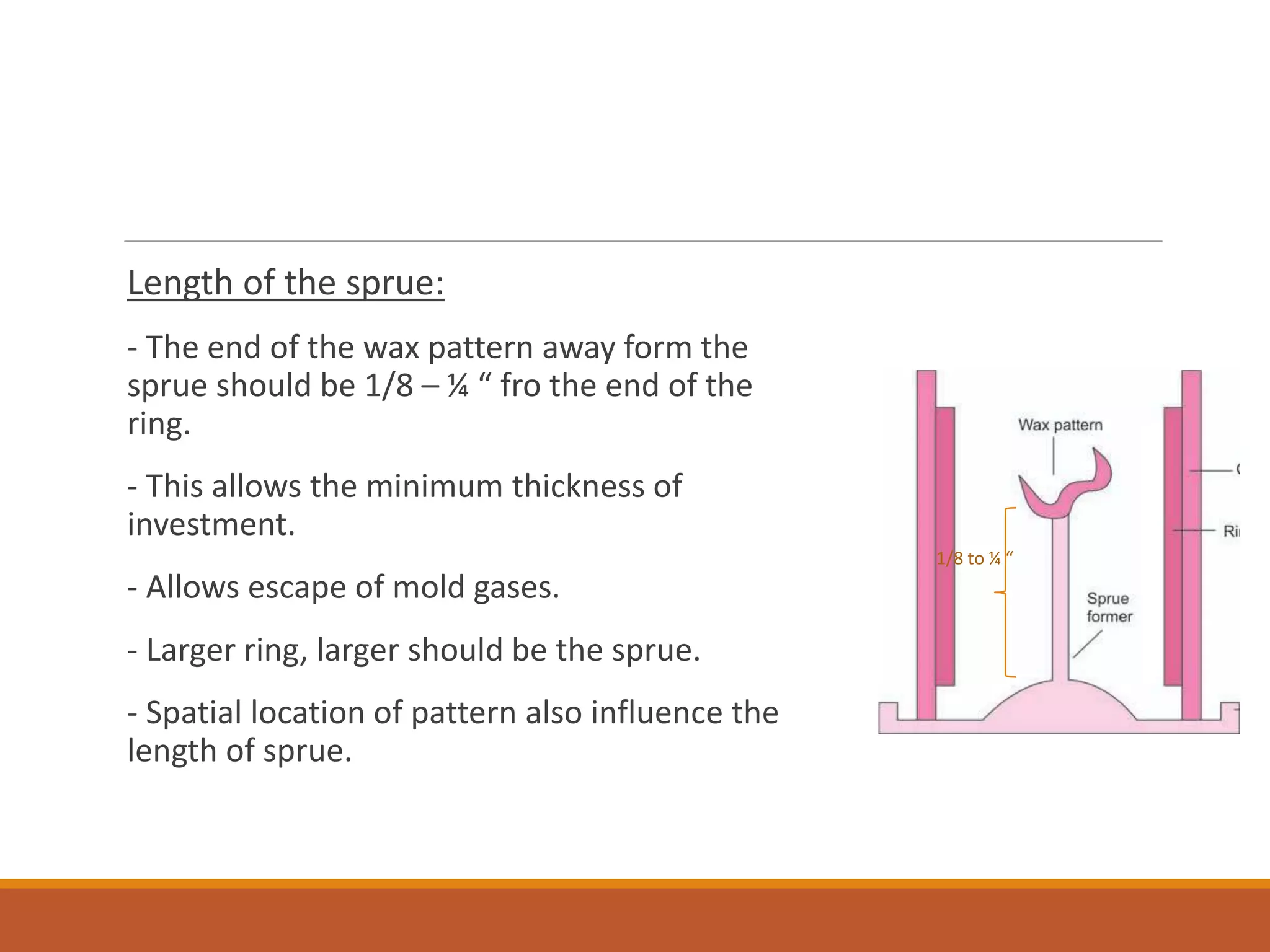

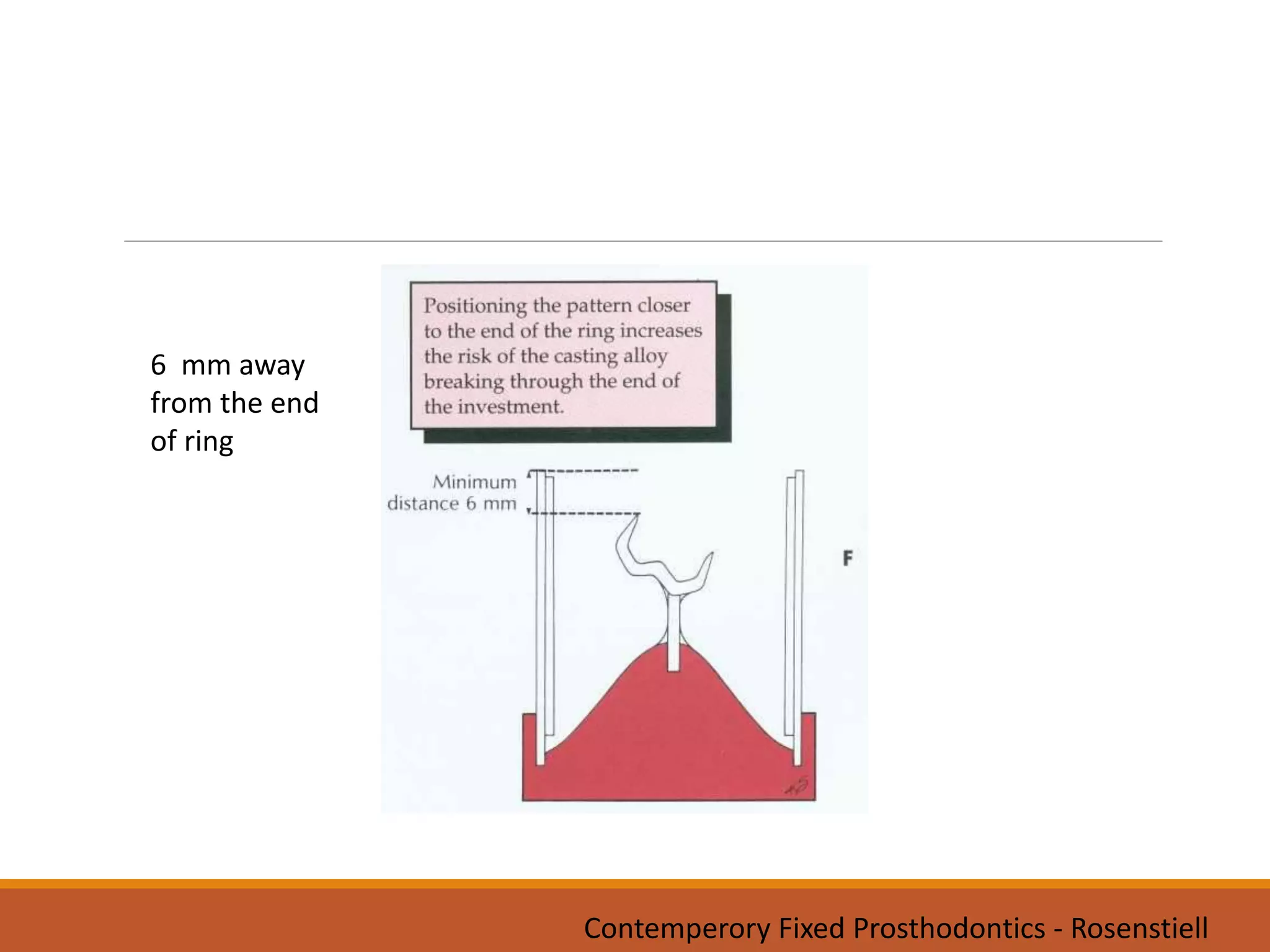

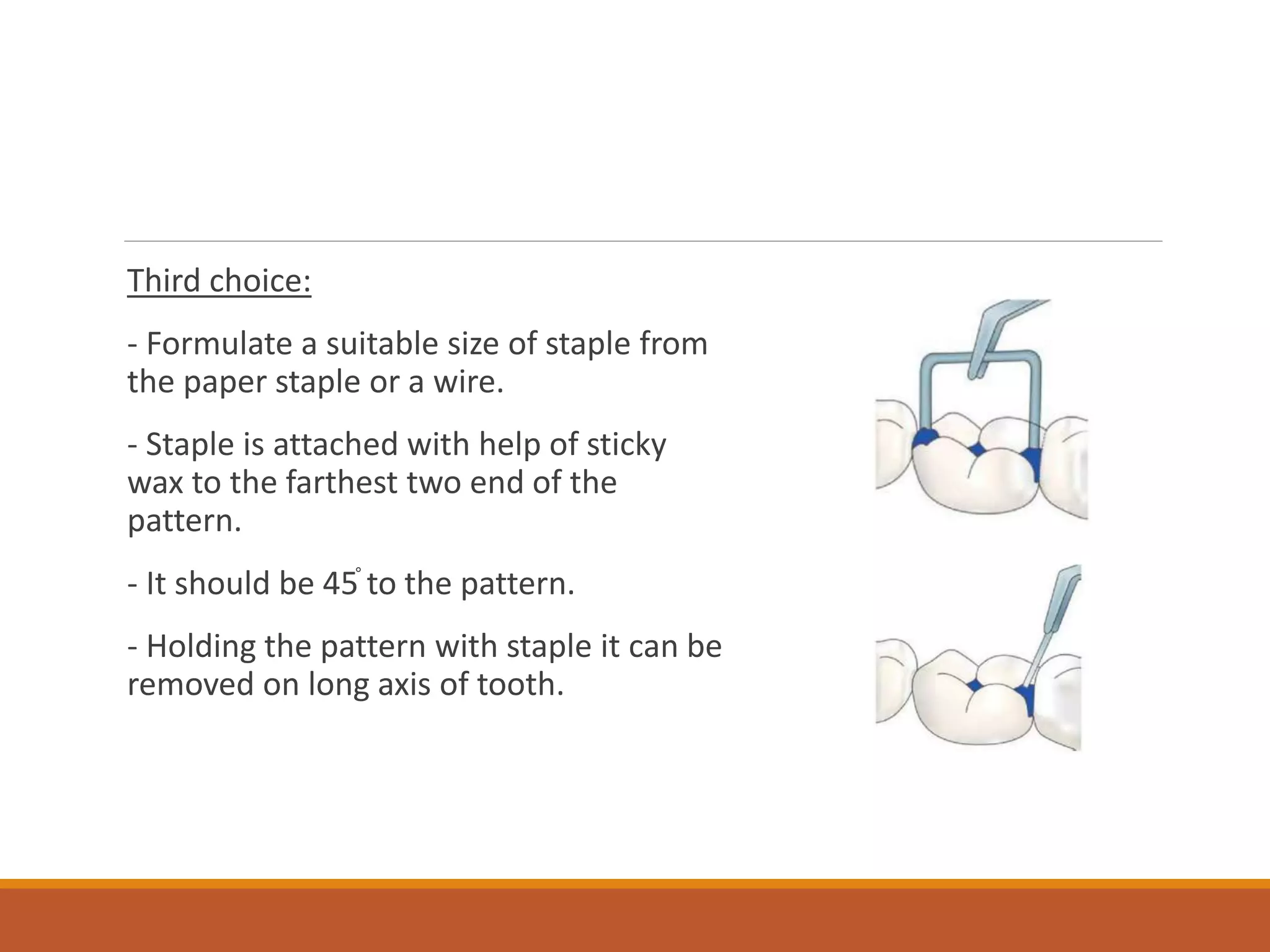

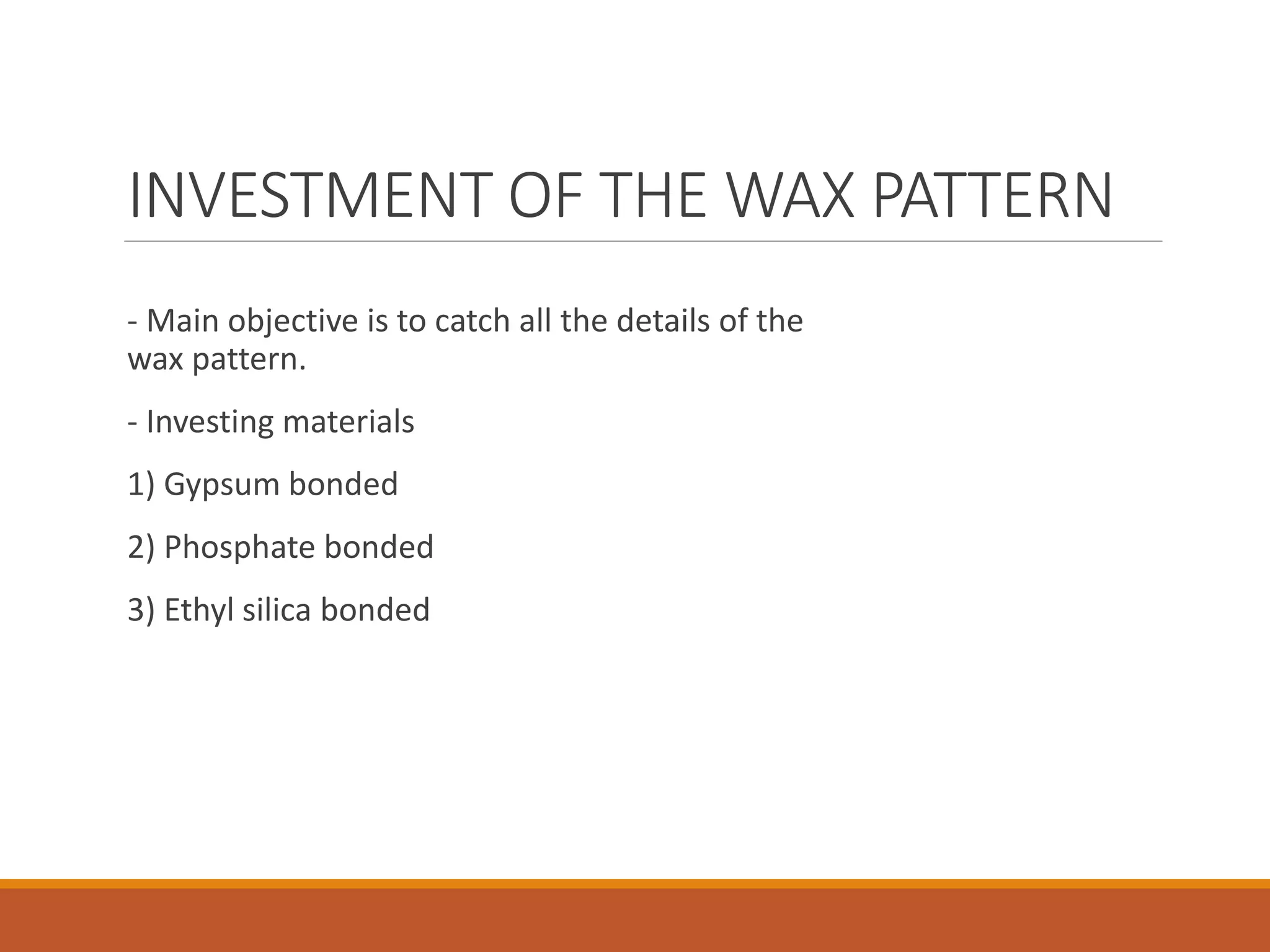

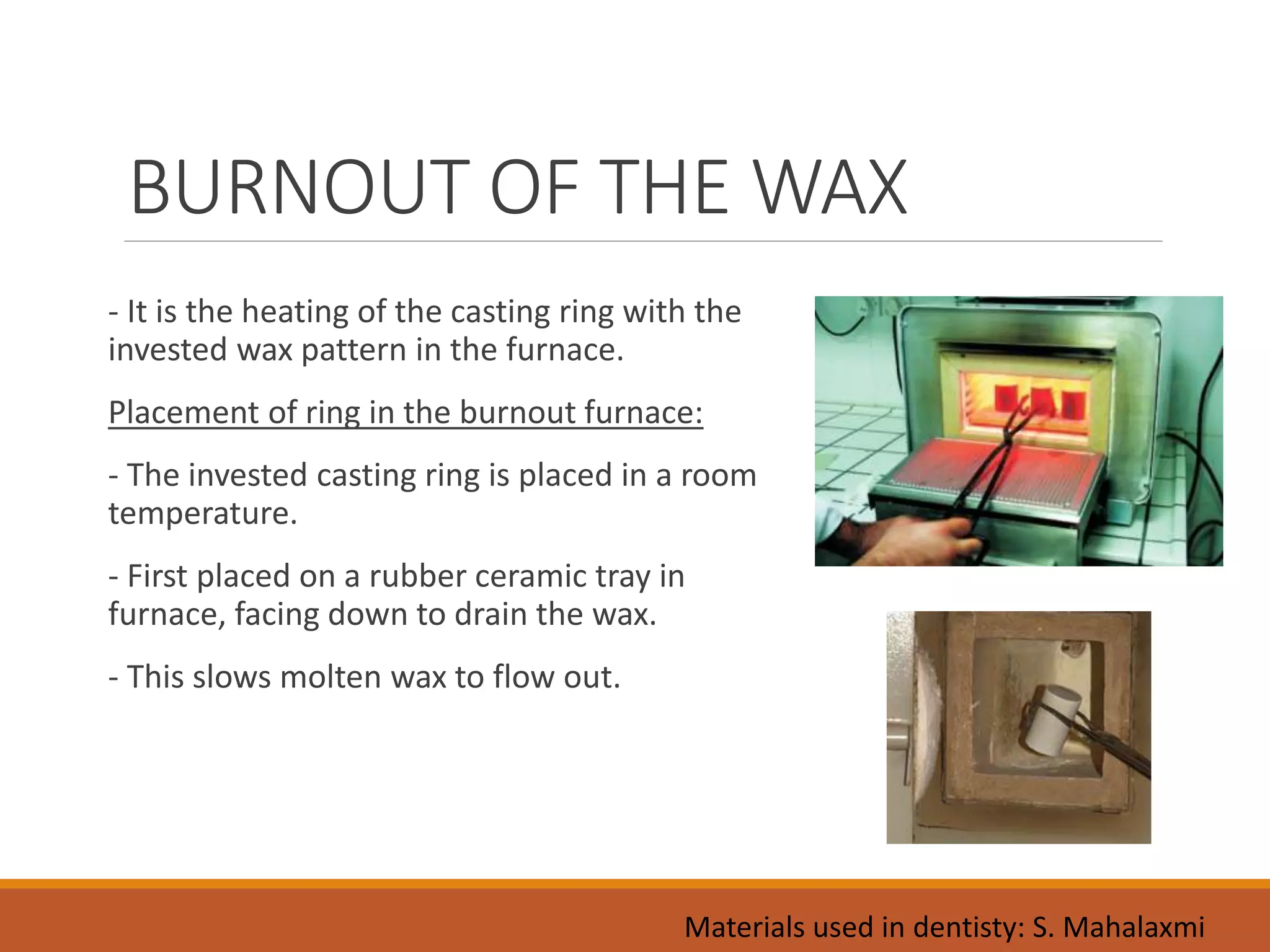

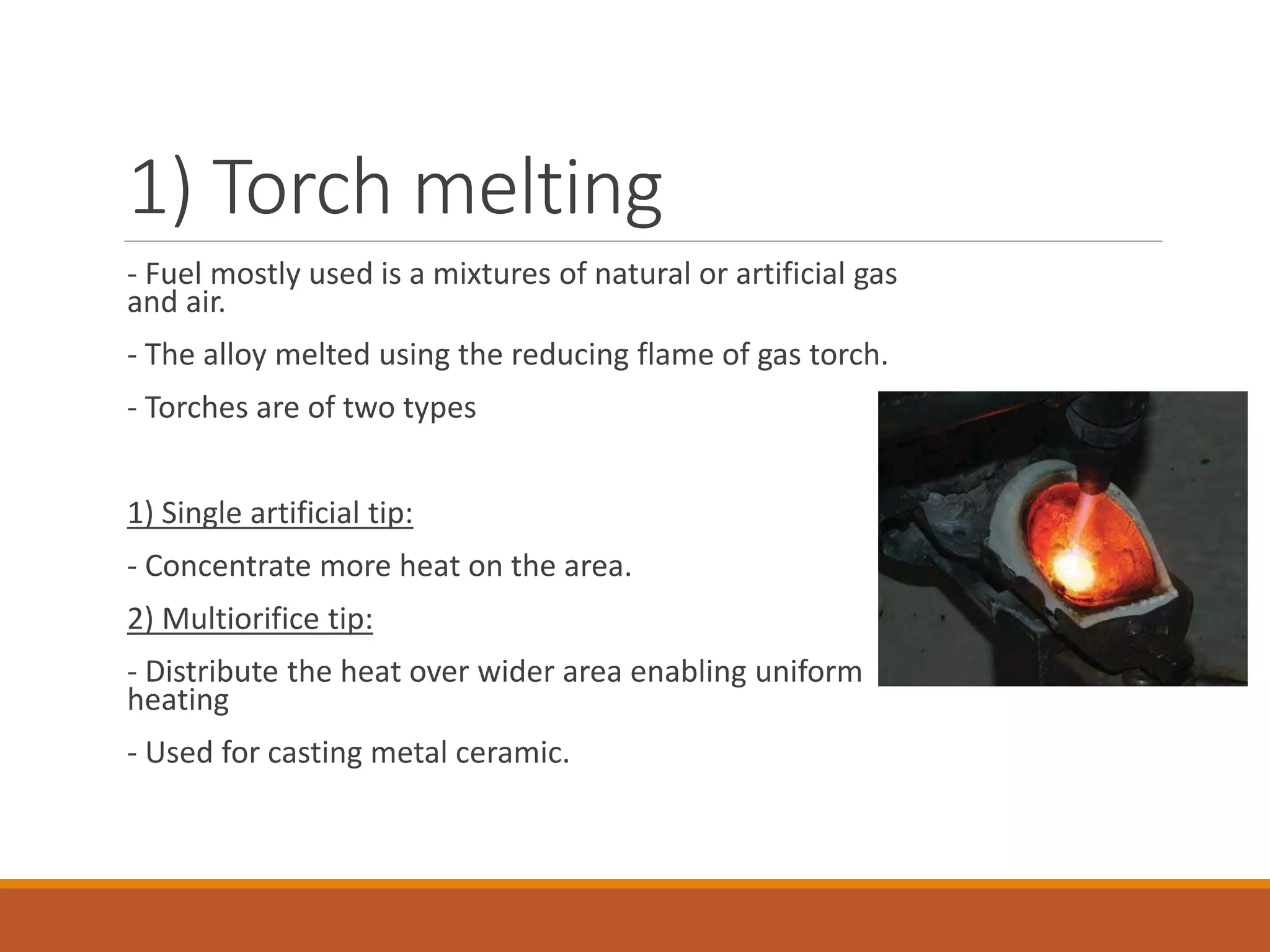

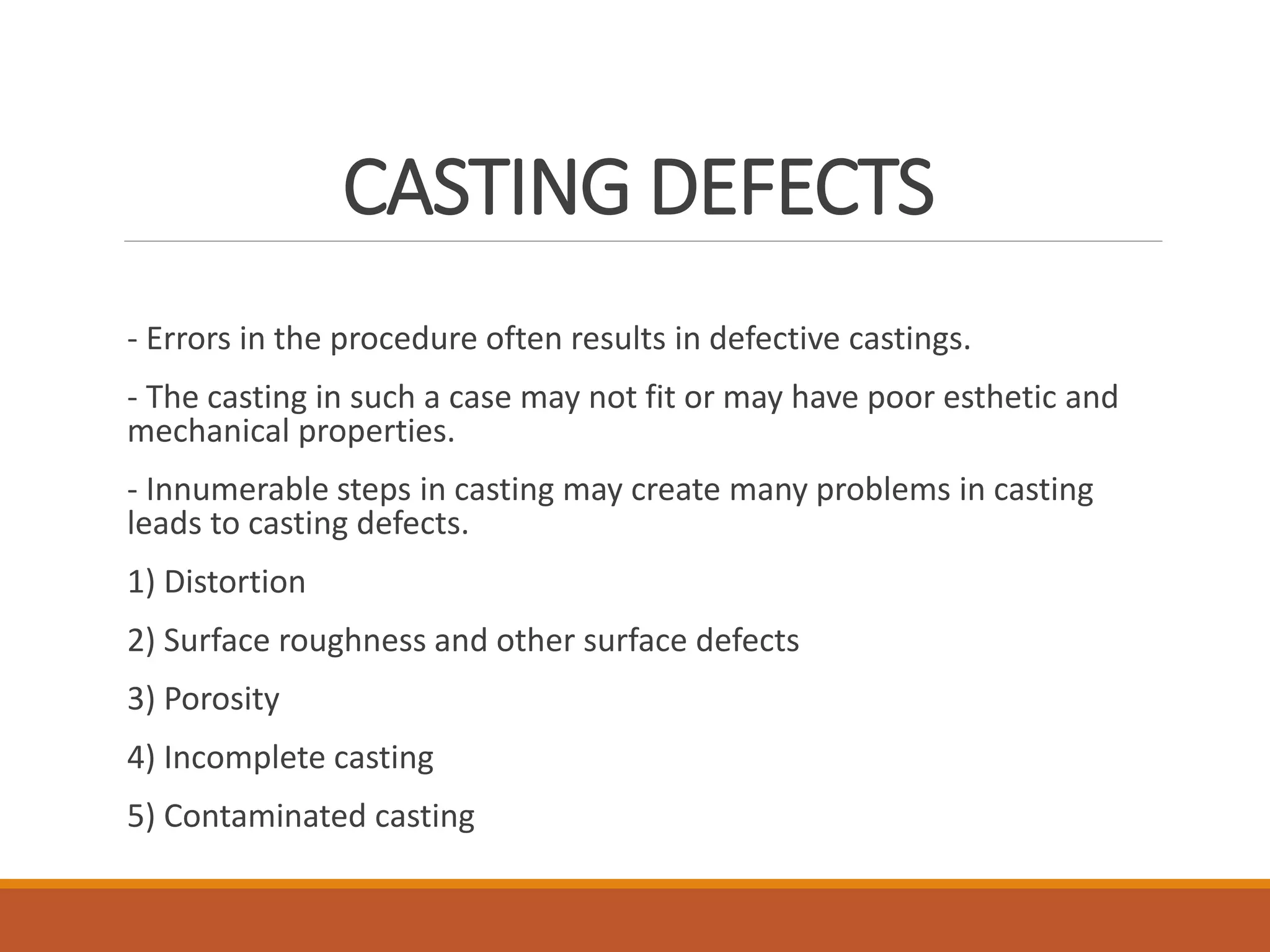

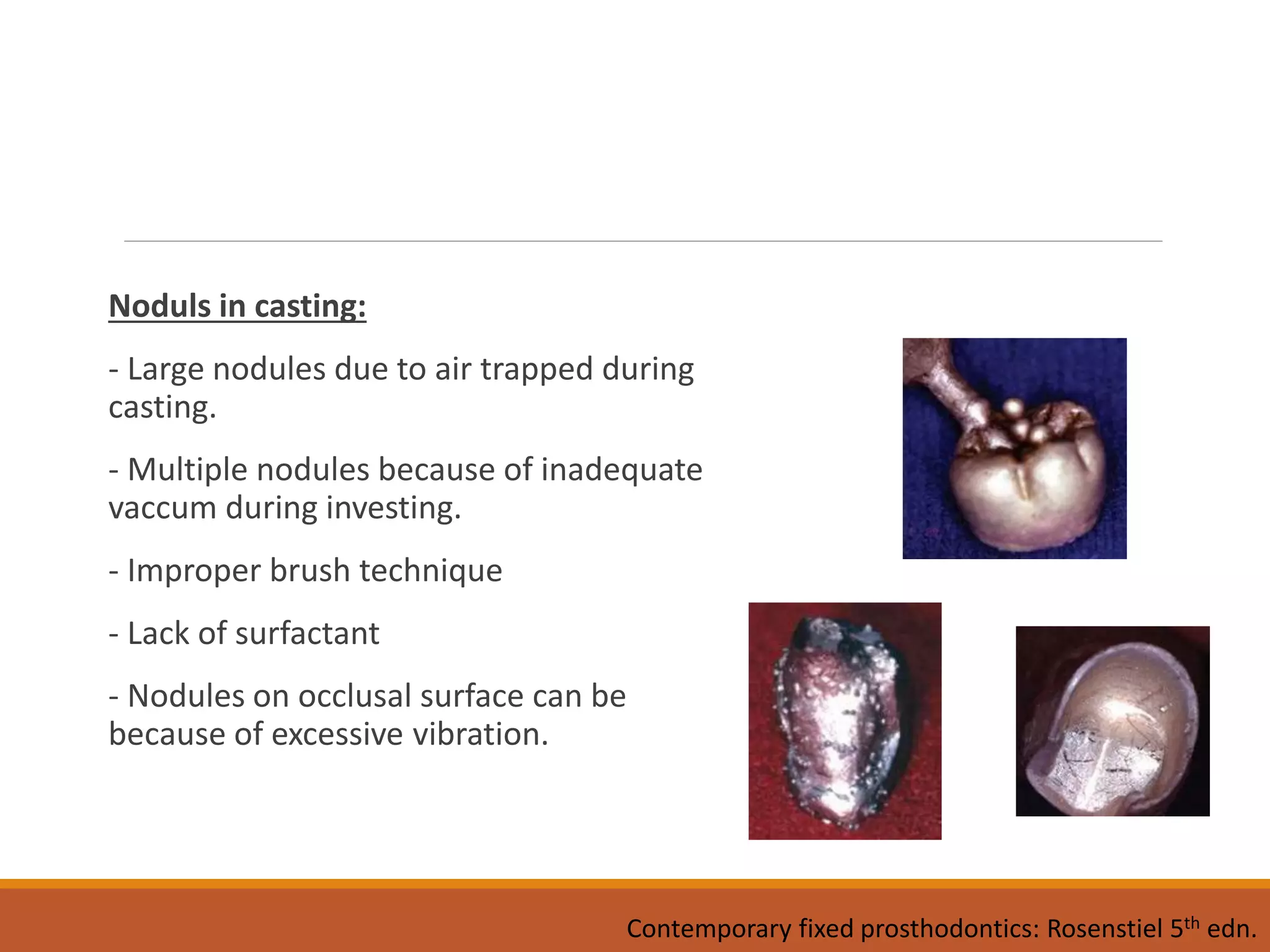

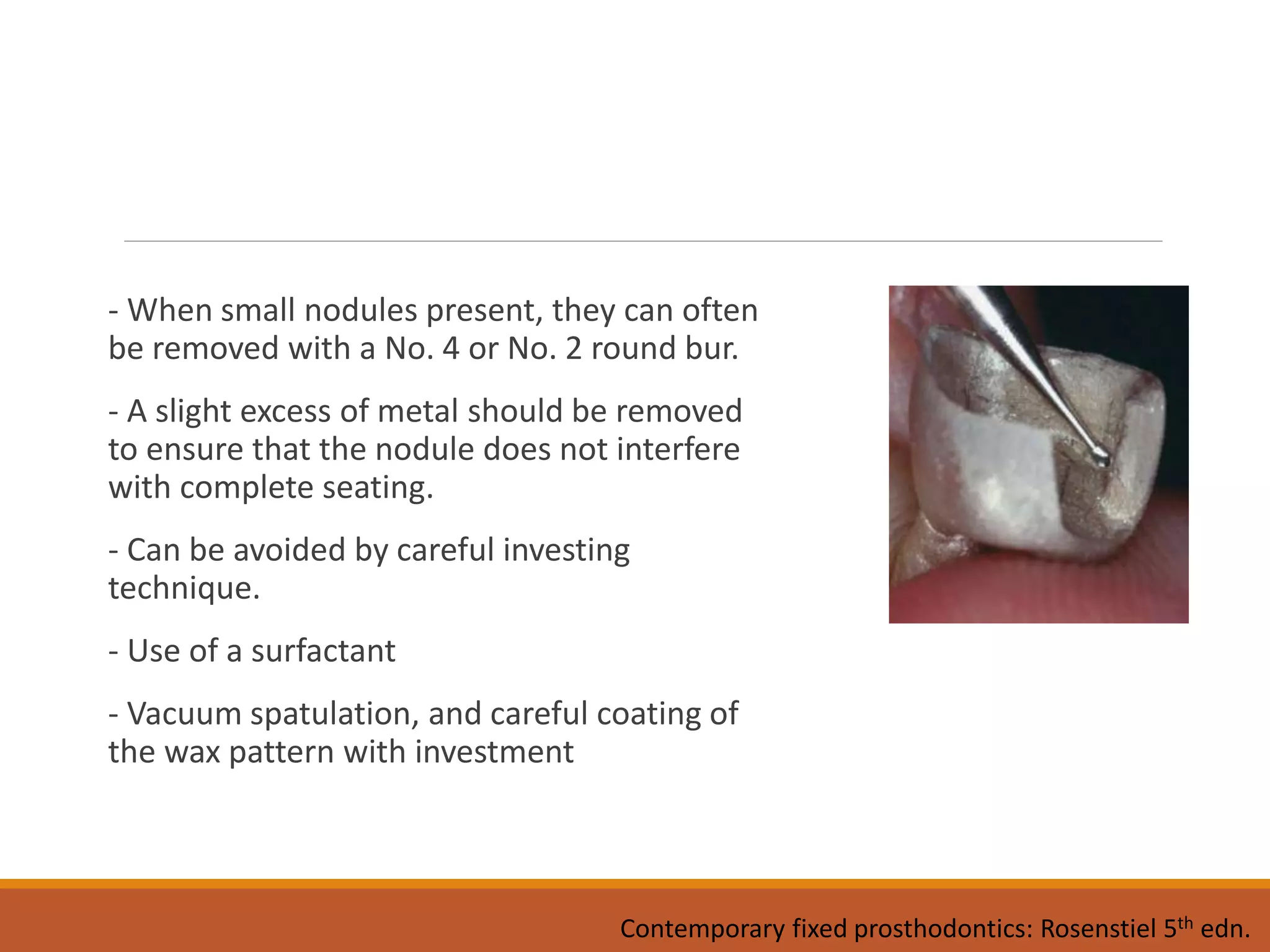

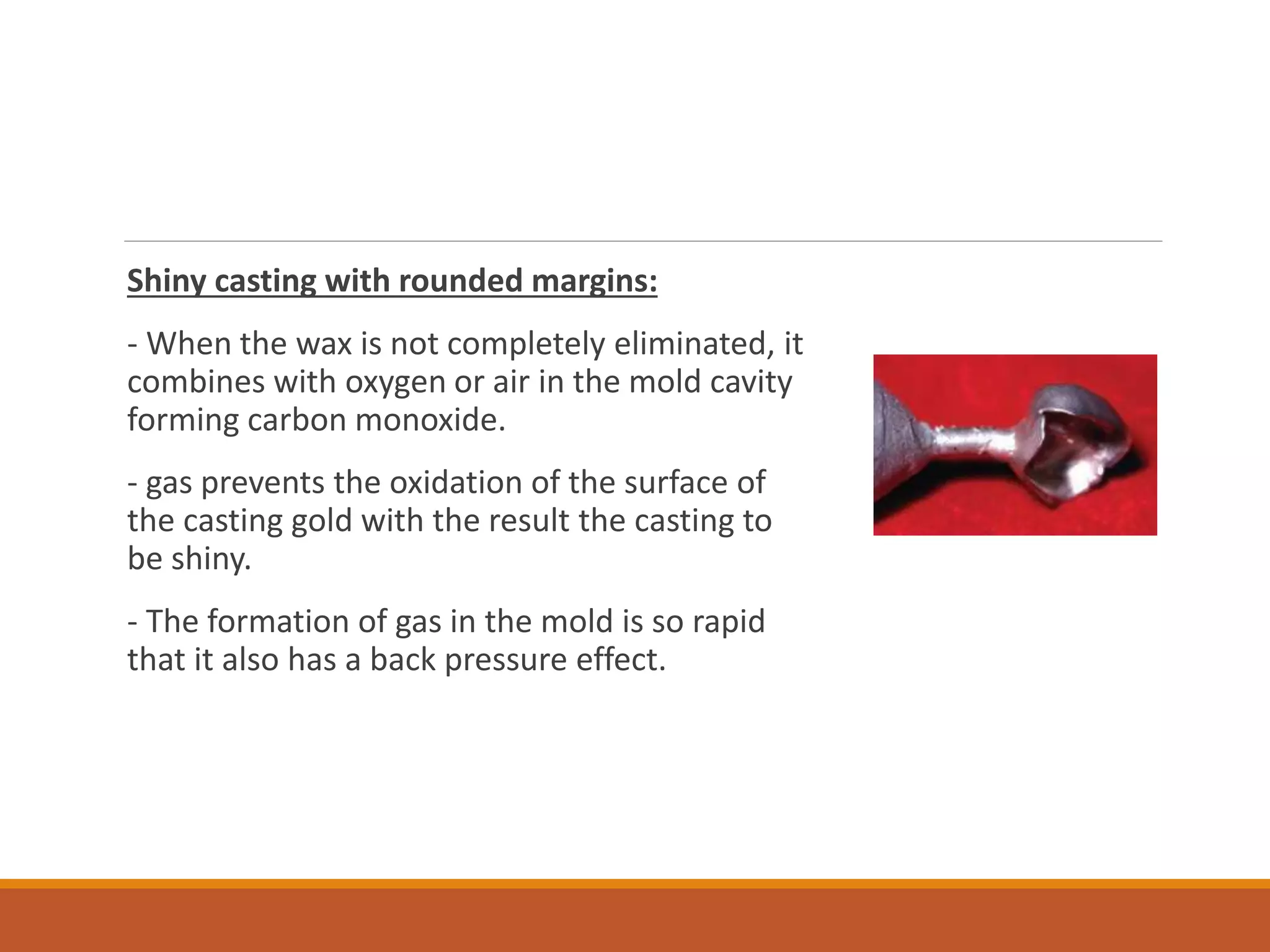

The document provides a comprehensive overview of casting procedures in dentistry, detailing the definition, historical developments, and the steps involved in producing working casts and dies. It outlines techniques for creating wax patterns, spruing, investing molds, and the proper management of casting defects. Key considerations for materials, methods, and tools used in dental casting are also discussed, offering essential guidelines for practitioners.