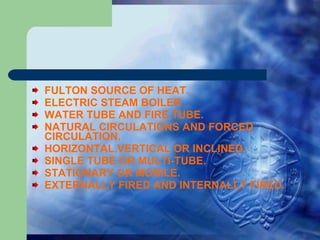

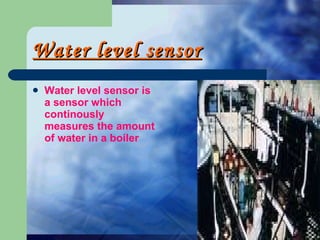

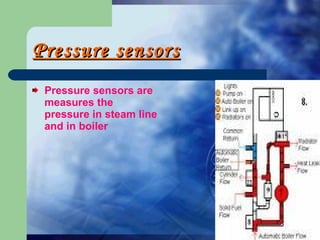

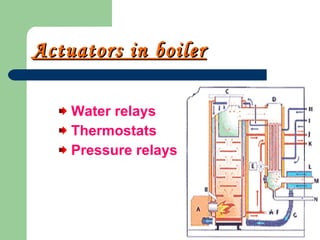

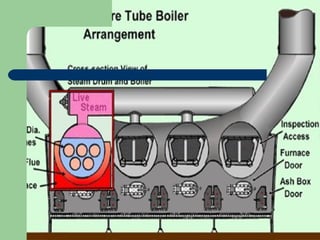

A boiler is a closed vessel that transfers heat from fuel combustion to water, converting it into steam for power generation, industrial processes, and heating. Boilers are classified based on their heat source, circulation method, orientation, and whether they are stationary or mobile. A boiler is a mechatronics system that uses sensors to monitor heat, water level, and pressure, sending signals to a control unit consisting of a microcontroller and other components that regulate the system without human interference through actuators like water valves.