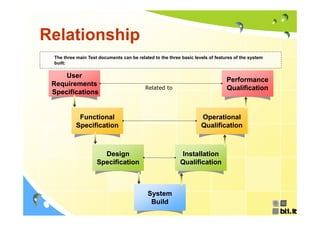

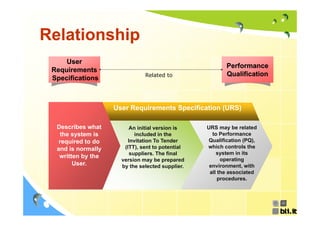

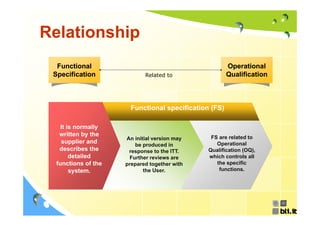

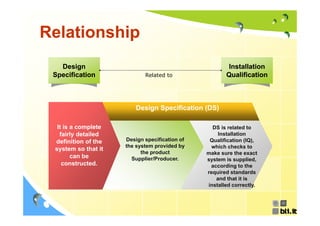

This document discusses concepts regarding the GAMP Guide. It provides an overview of key terms like GAMP and GMP. It outlines the origin of the GAMP Guide in the early 1990s to improve understanding of pharmaceutical regulation and validation. It describes the general validation process activities of planning, specifications, test planning, testing, and review. It explains the relationship between user requirements, functional specifications, design specifications, and the different qualification documents. Finally, it acknowledges the reader.

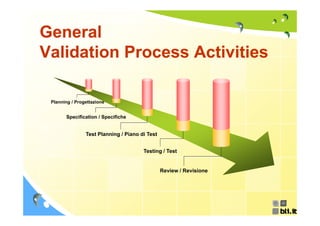

![General

Validation Process Activities

Planning

[progettazione]

Written Validation Plan

(Piano di Validazione).](https://image.slidesharecdn.com/bli-it-concepts-regarding-gamp-guide-en-120405050728-phpapp02/85/Bli-it-concepts-regarding-gamp-guide-en-7-320.jpg)

![General

Validation Process Activities

Specifications

[specifiche]

Specify and agree what is required.

required](https://image.slidesharecdn.com/bli-it-concepts-regarding-gamp-guide-en-120405050728-phpapp02/85/Bli-it-concepts-regarding-gamp-guide-en-8-320.jpg)

![General

Validation Process Activities

Test Planning IQ [installation qualification]

OQ [operational qualification]

[piano di test] PQ [performance qualification]

Prepare document to describe how the system is to be

tested.](https://image.slidesharecdn.com/bli-it-concepts-regarding-gamp-guide-en-120405050728-phpapp02/85/Bli-it-concepts-regarding-gamp-guide-en-9-320.jpg)

![General Validation Process

Activities

Testing IQ [installation qualification]

OQ [operational qualification]

[test] PQ [performance qualification]

Perform tests and collect results

results.](https://image.slidesharecdn.com/bli-it-concepts-regarding-gamp-guide-en-120405050728-phpapp02/85/Bli-it-concepts-regarding-gamp-guide-en-10-320.jpg)

![General Validation

G l V lid ti

Process Activities

Review

[revisione]

Review results to show that the system performs as

specified plus any reservations.](https://image.slidesharecdn.com/bli-it-concepts-regarding-gamp-guide-en-120405050728-phpapp02/85/Bli-it-concepts-regarding-gamp-guide-en-11-320.jpg)