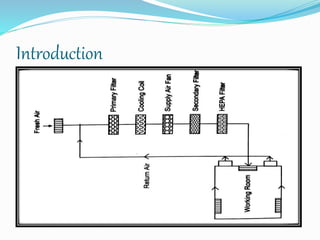

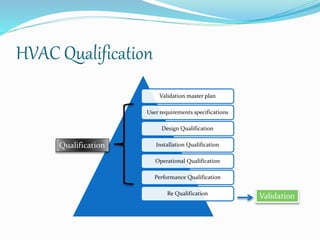

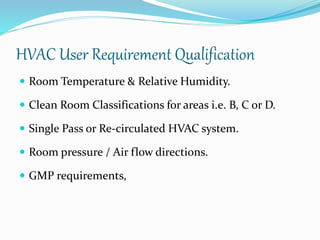

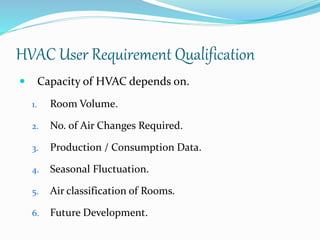

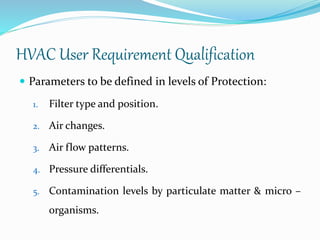

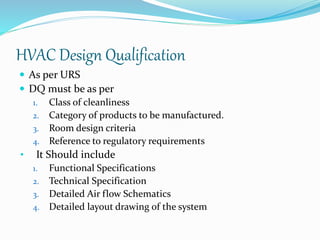

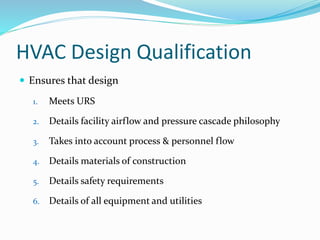

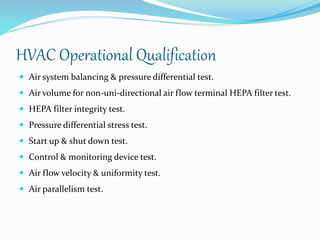

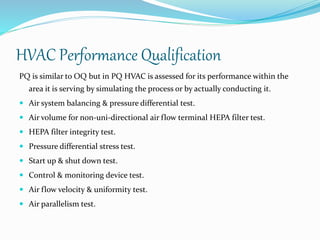

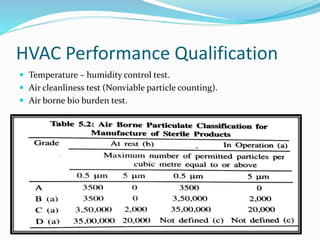

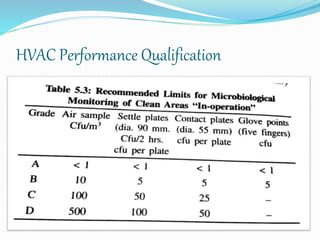

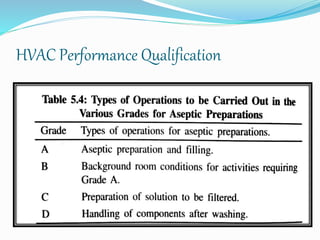

This document discusses the user requirement specifications (URS), design qualification (DQ), installation qualification (IQ), operational qualification (OQ), and performance qualification (PQ) of heating, ventilation, and air conditioning (HVAC) systems used in pharmaceutical plants. The HVAC system must be qualified to ensure it is designed and installed properly and works as expected. The URS define the room temperature, humidity, and air cleanliness requirements. The DQ confirms the design meets the URS. The IQ verifies correct installation. The OQ tests the system operation. Finally, the PQ assesses the HVAC performance under normal operating conditions.