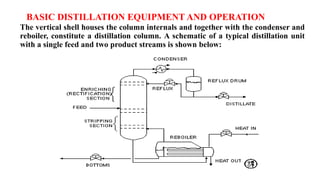

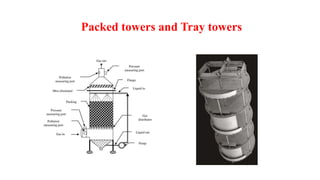

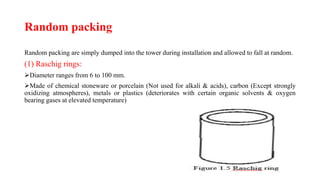

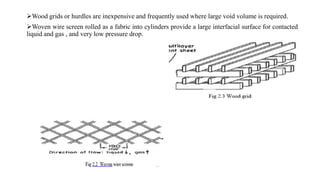

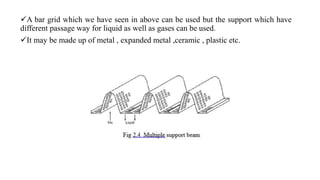

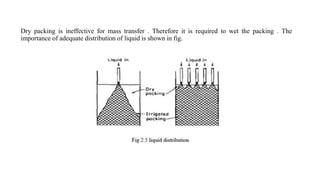

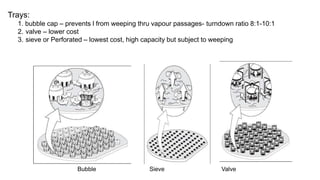

The document discusses basic distillation equipment and operation. It describes the main components of a distillation column including the shell, condenser, reboiler, and internals. It then focuses on packed towers, describing the types of packing materials used, including random packing like Raschig rings and structured packing. It also discusses design considerations for packing, liquid distribution, tray types for tray towers including bubble cap, valve, and sieve trays, and factors to consider when choosing between packed or tray towers.