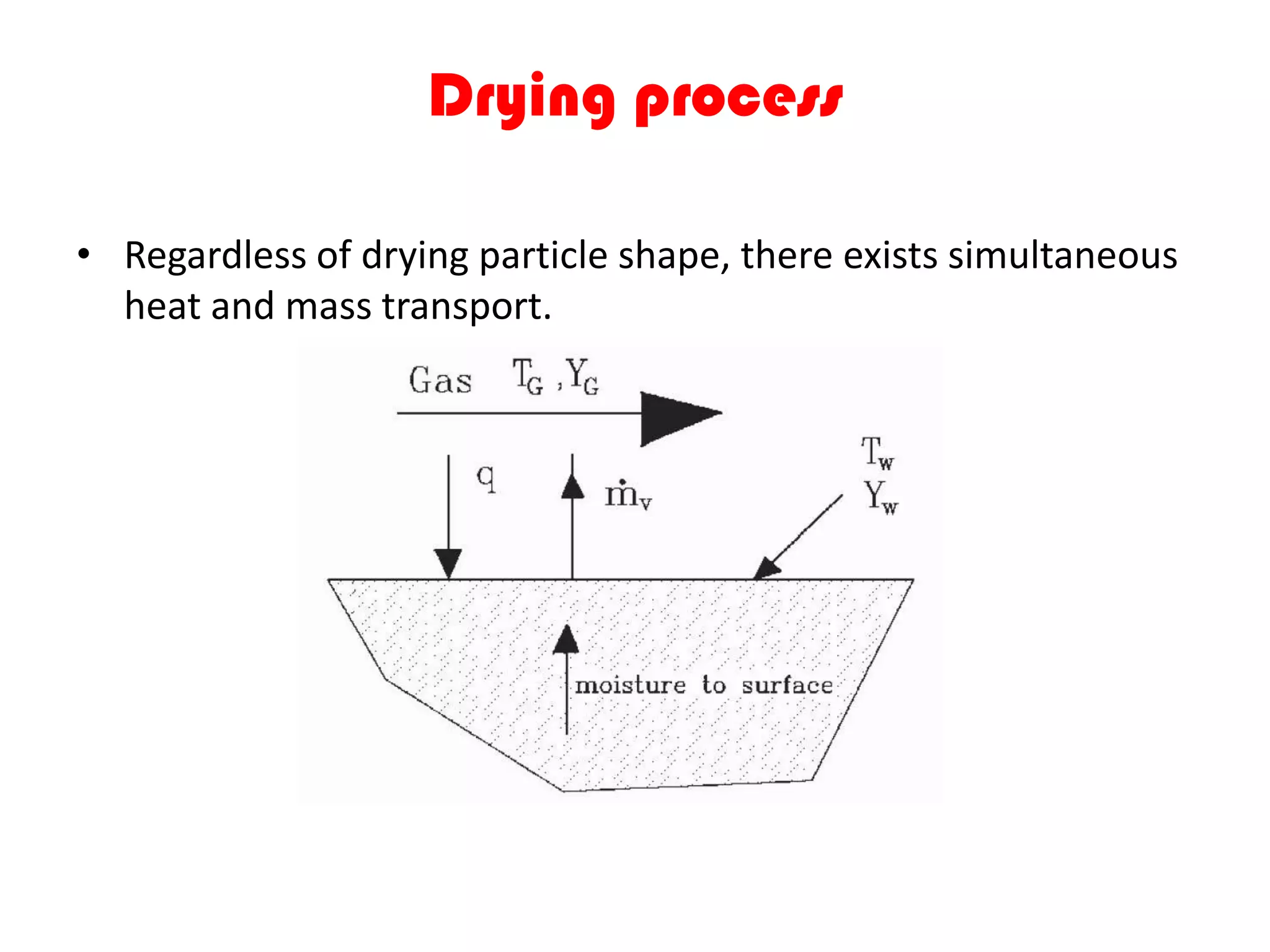

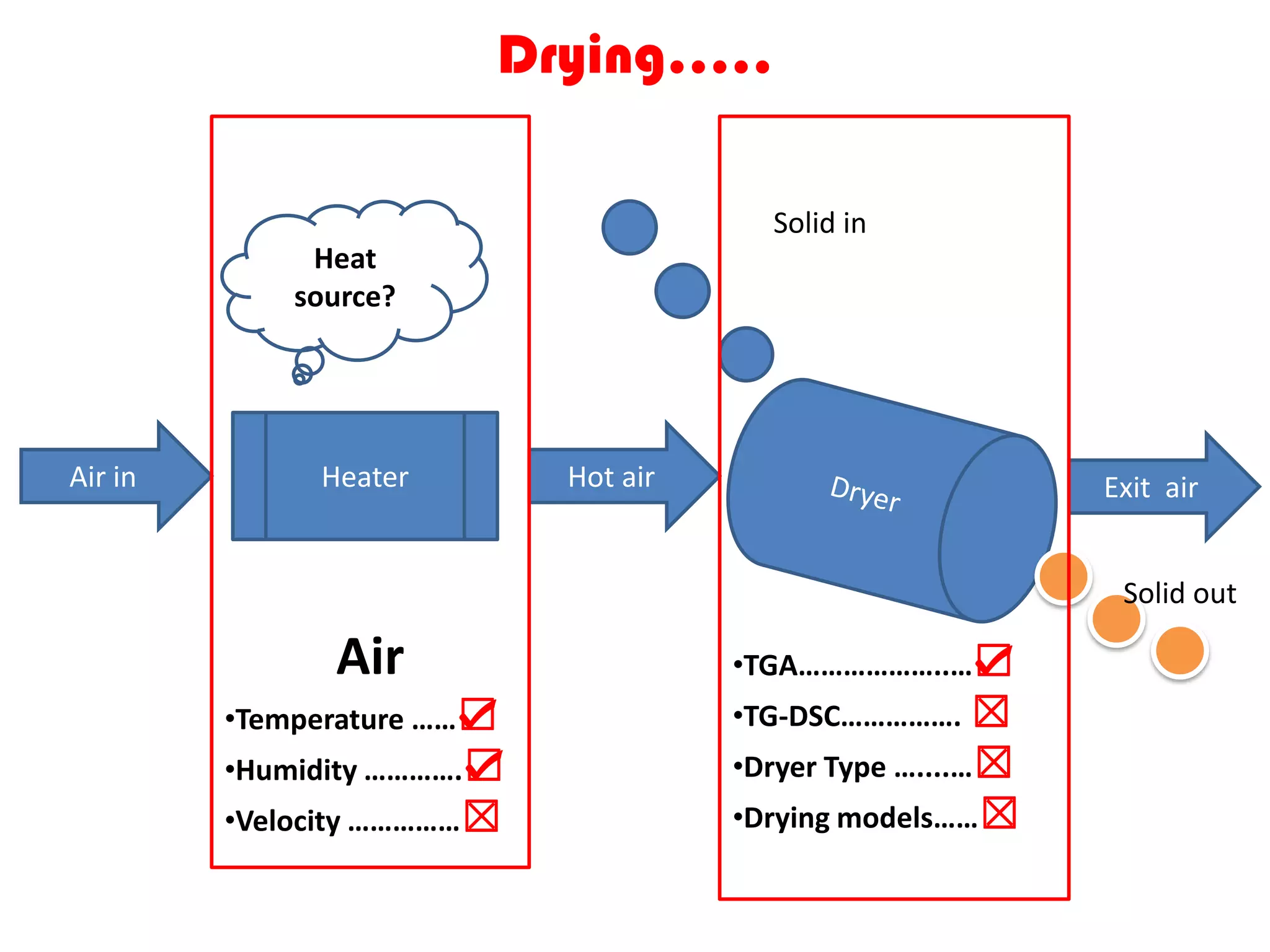

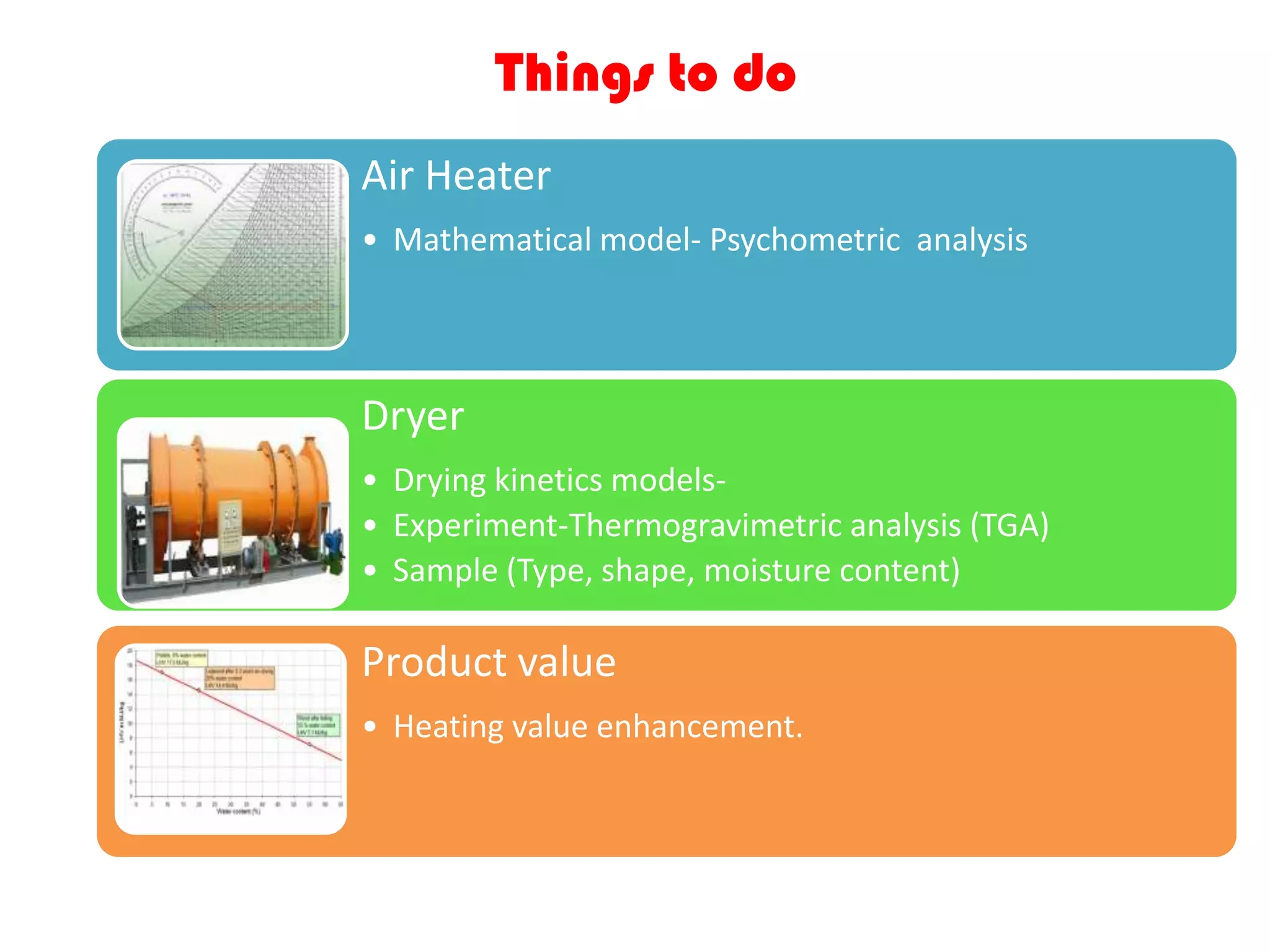

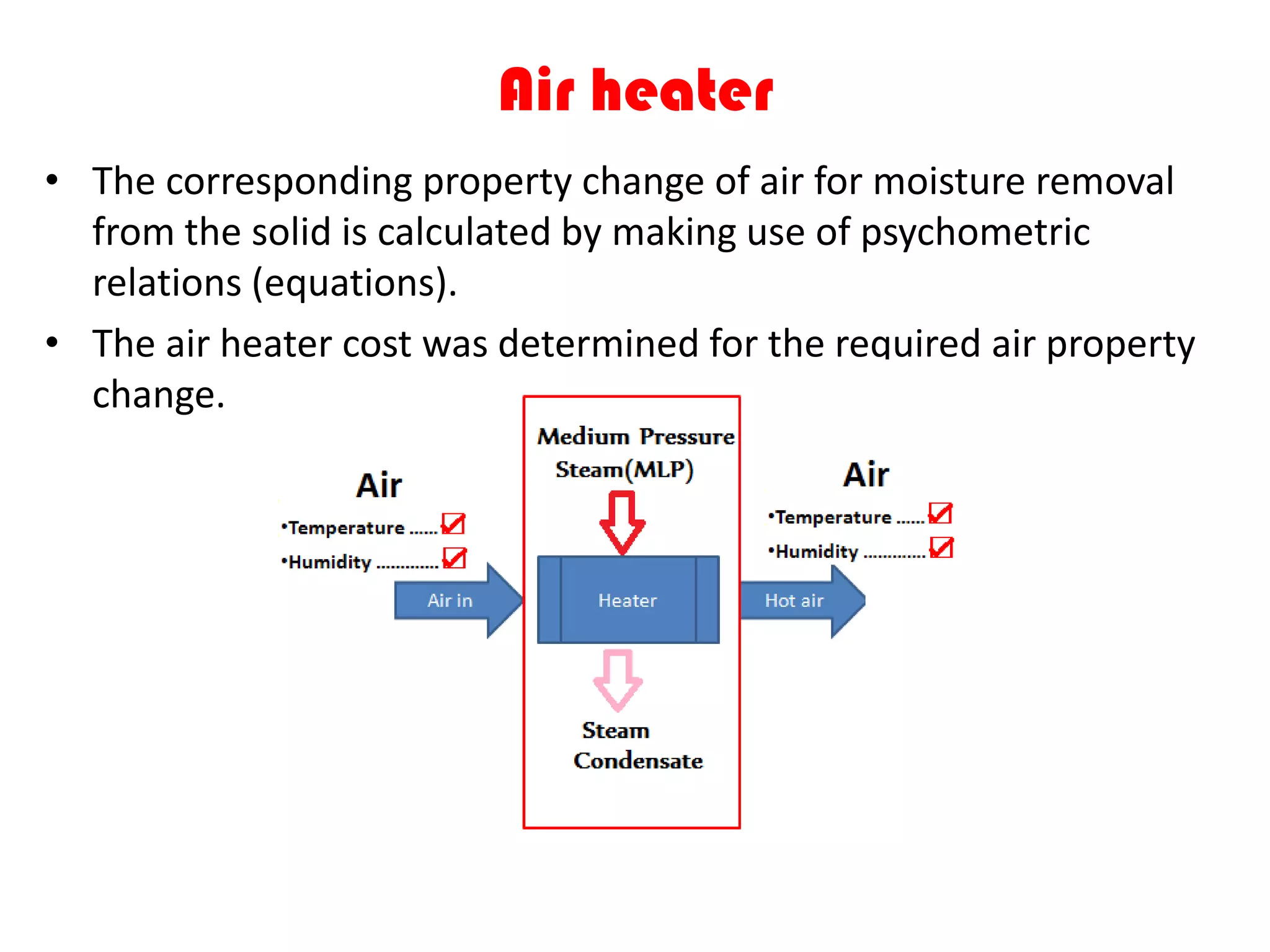

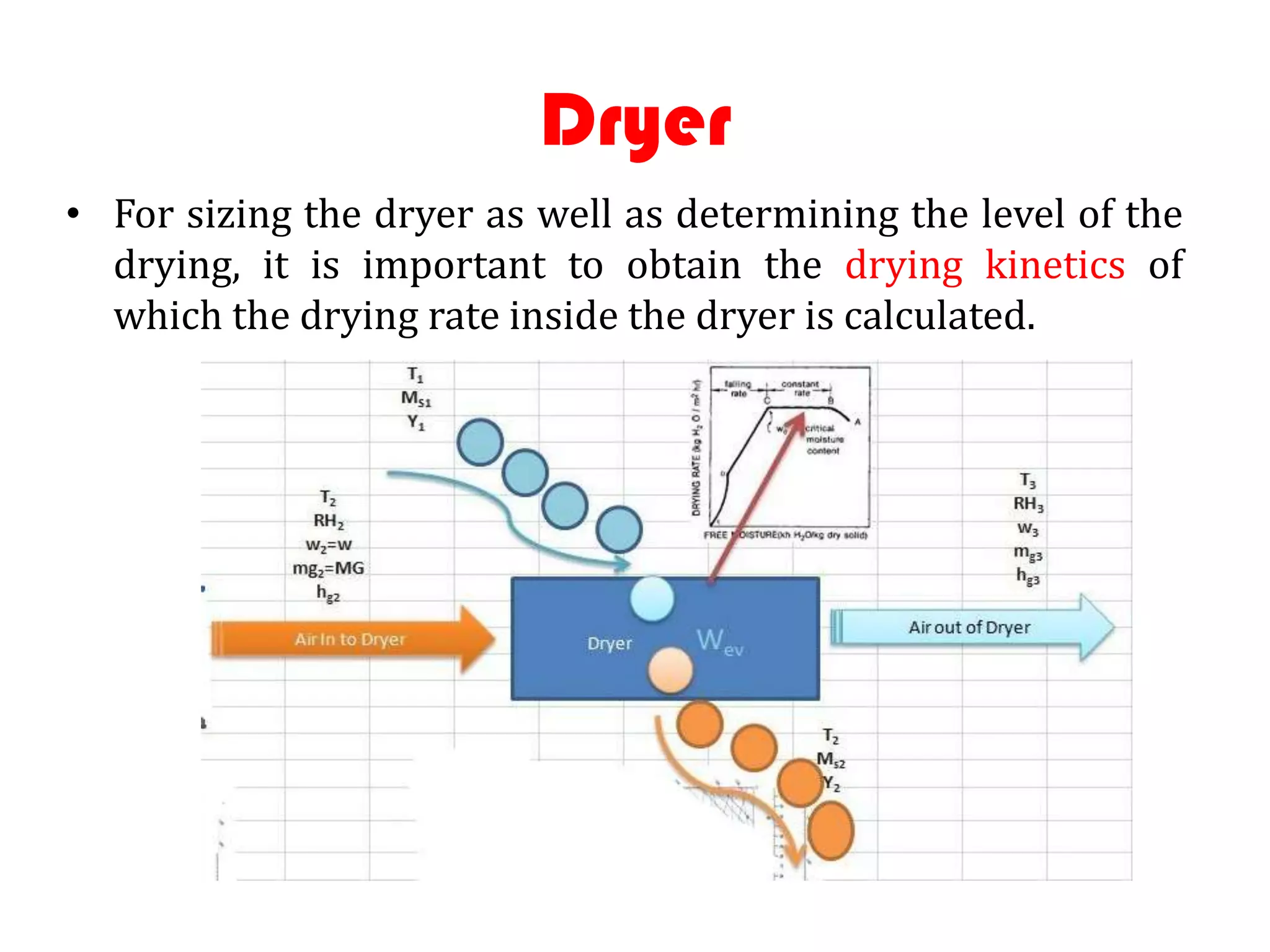

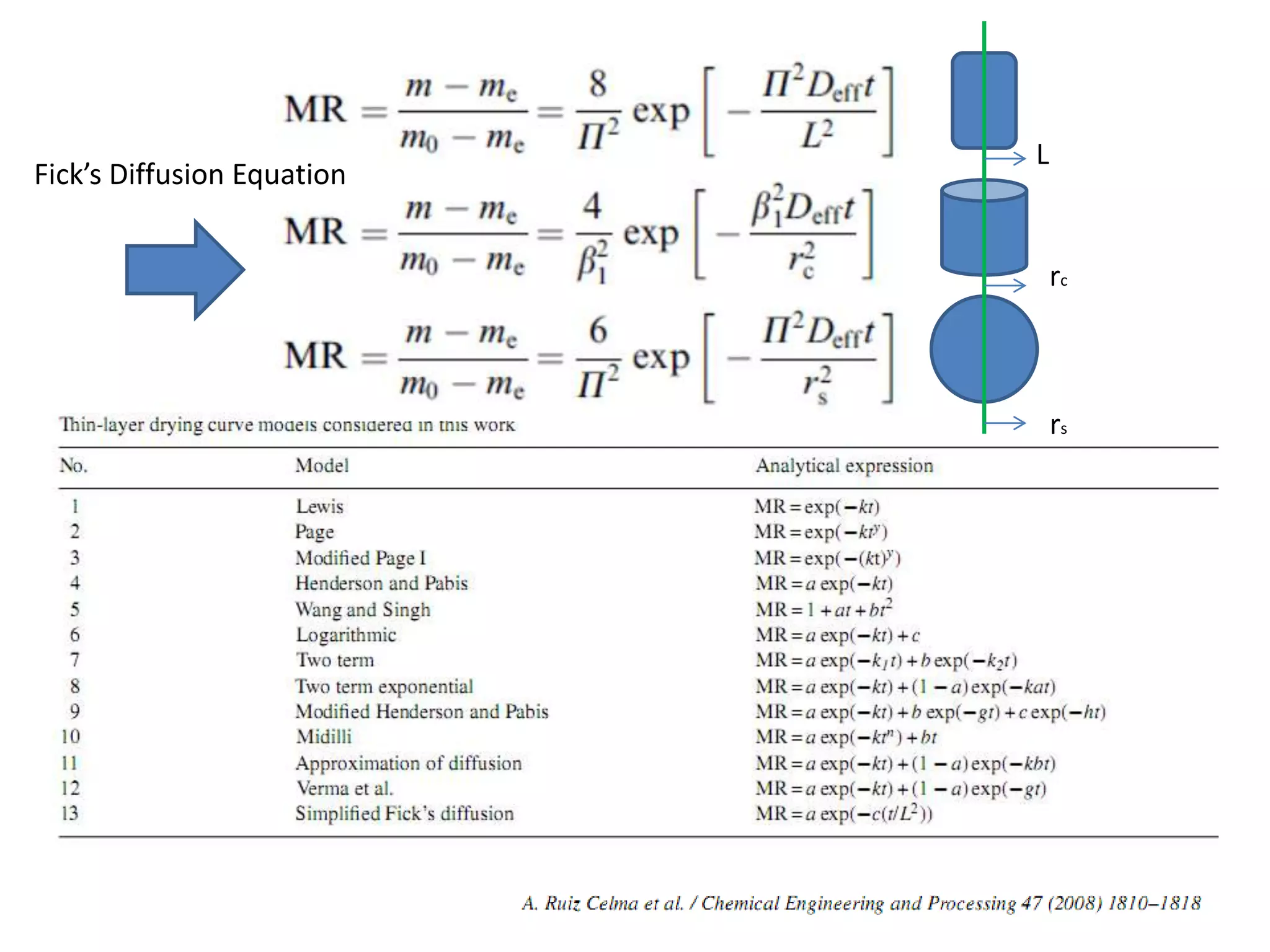

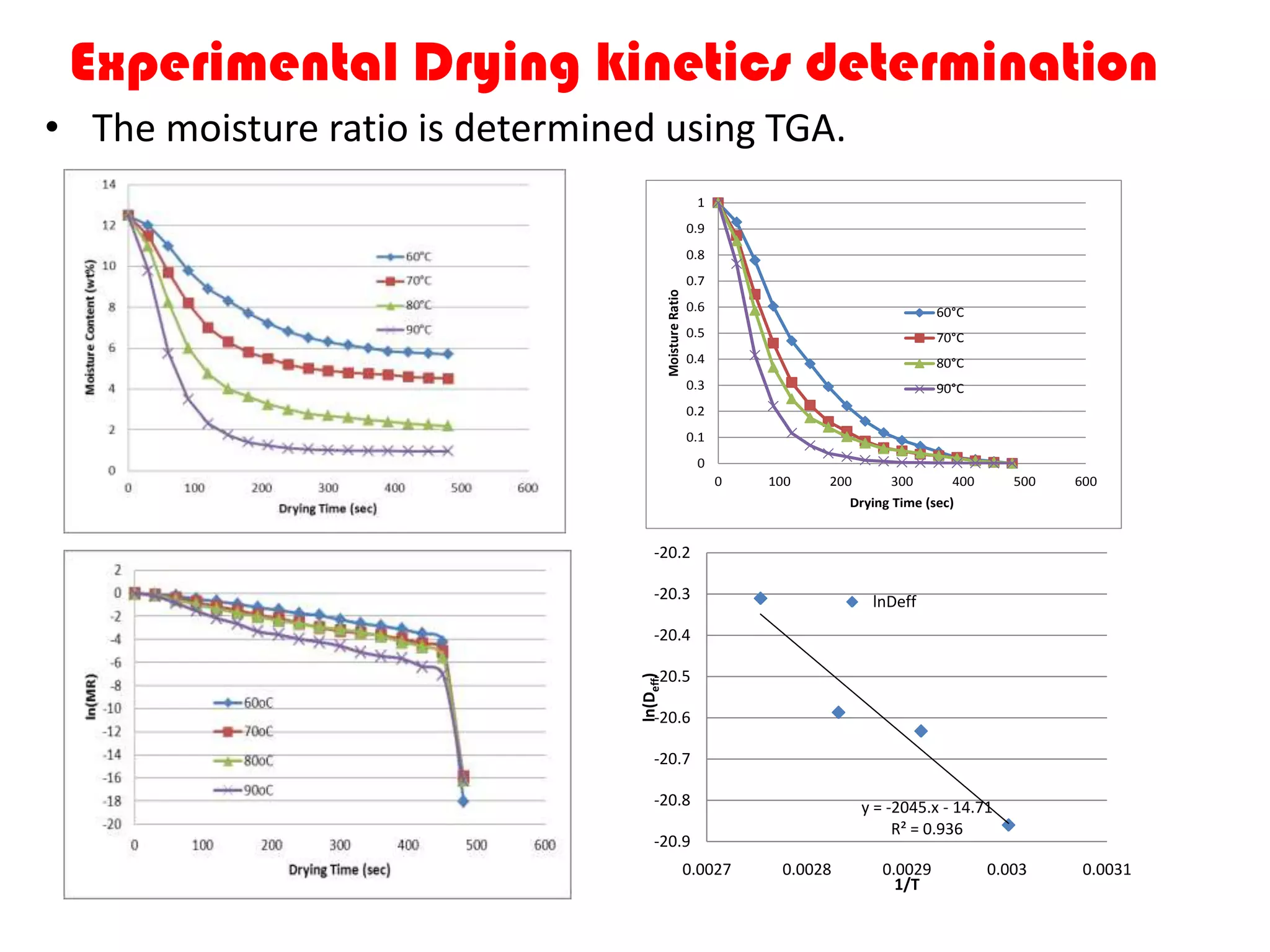

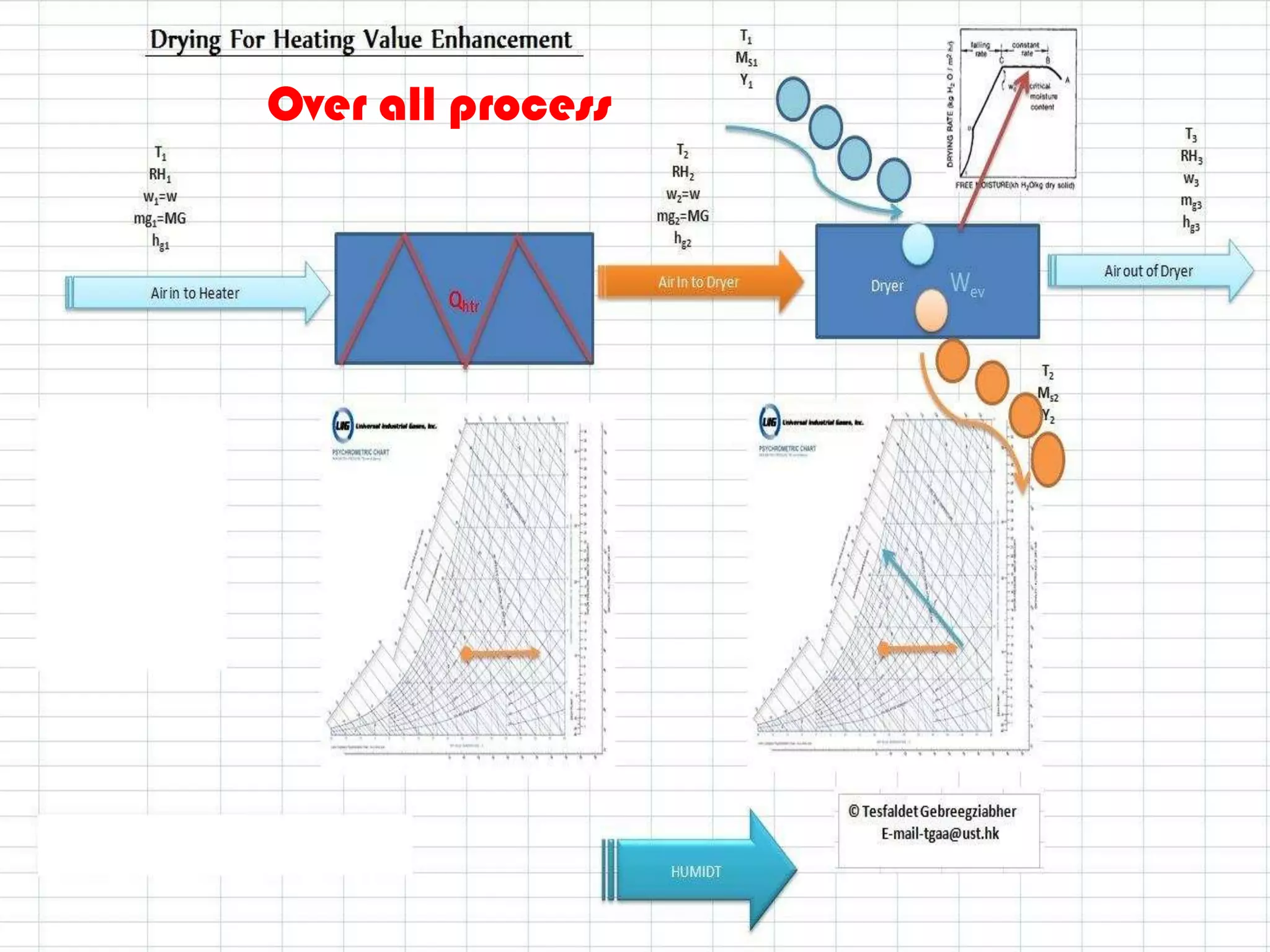

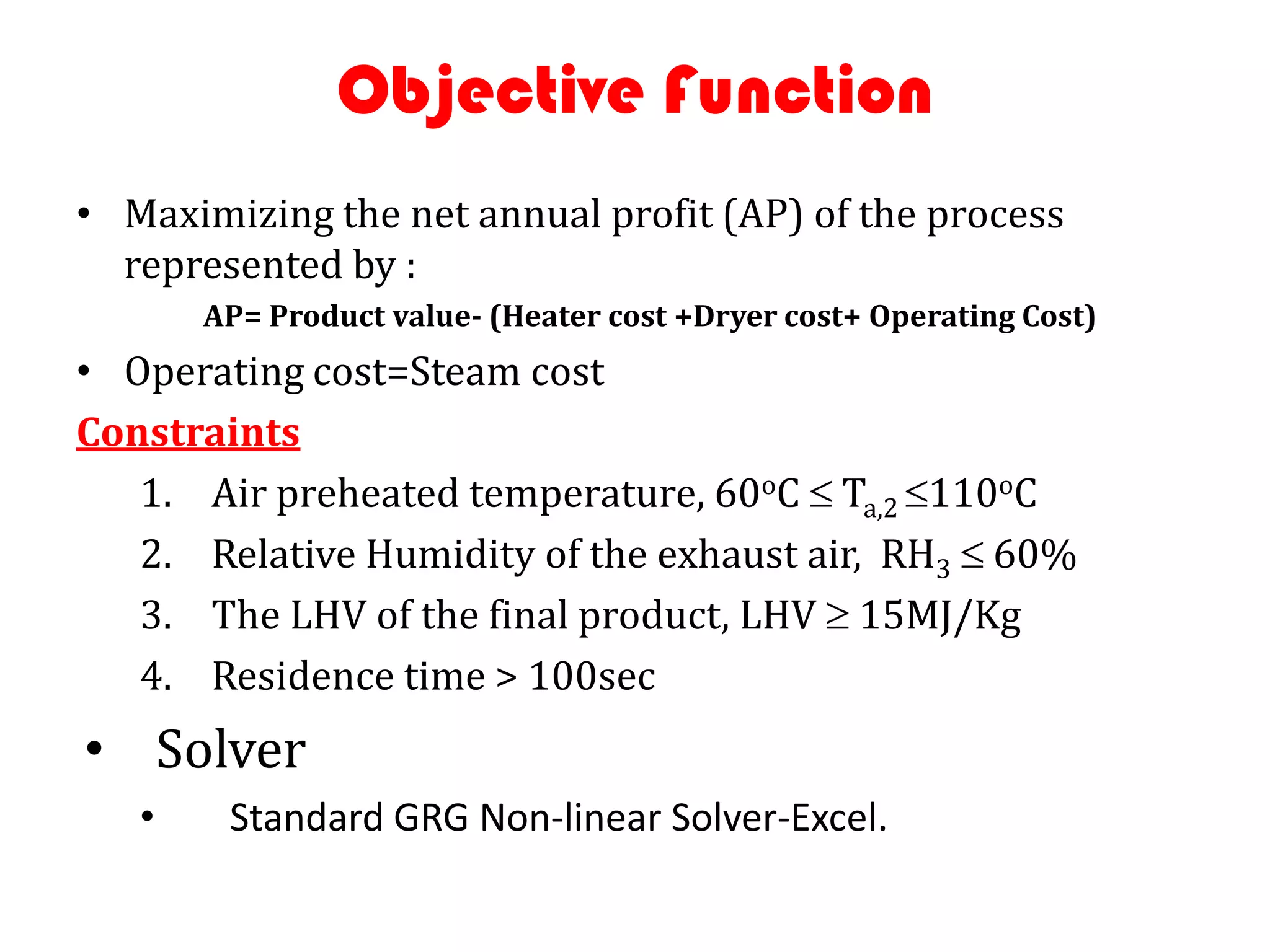

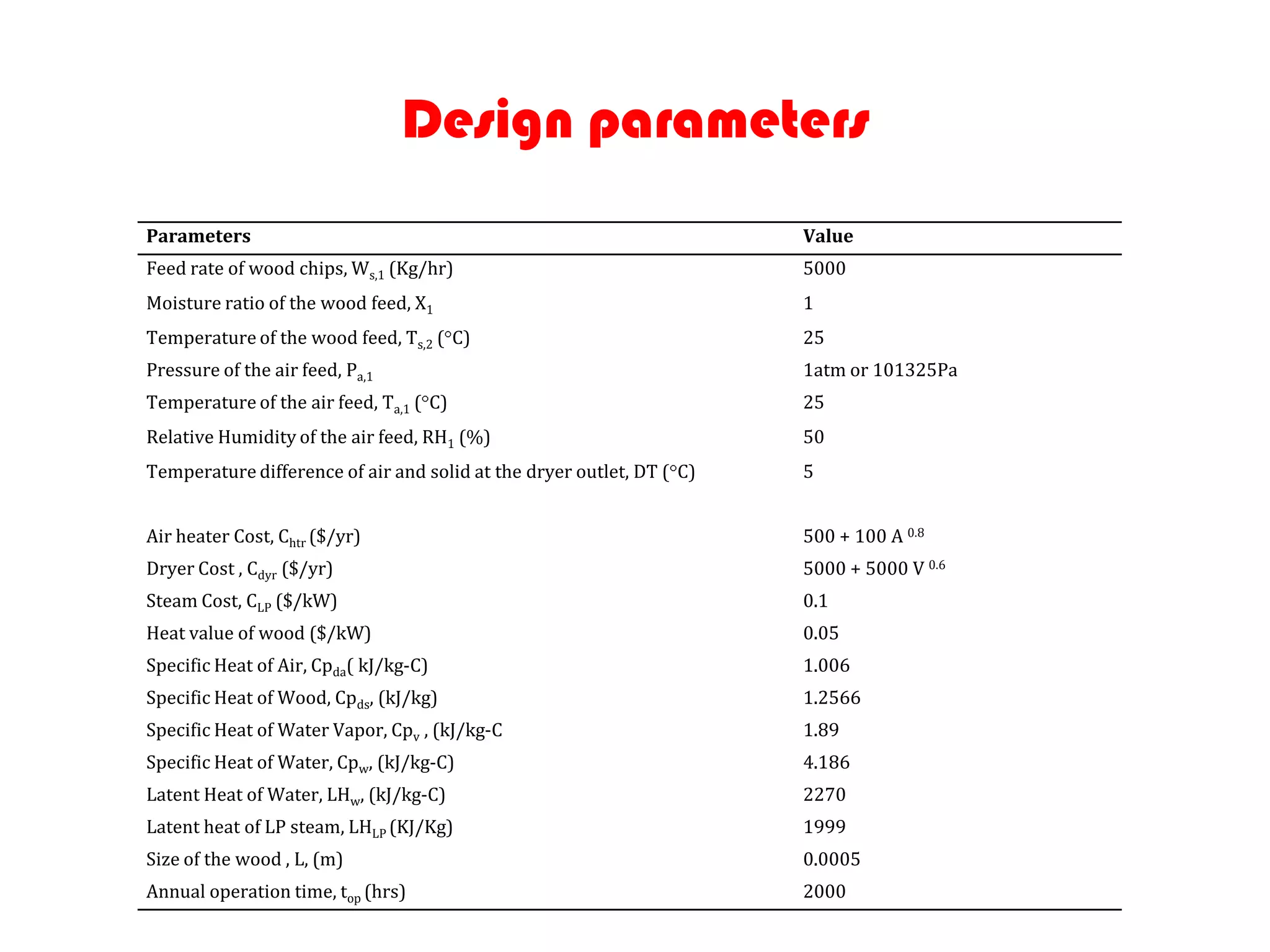

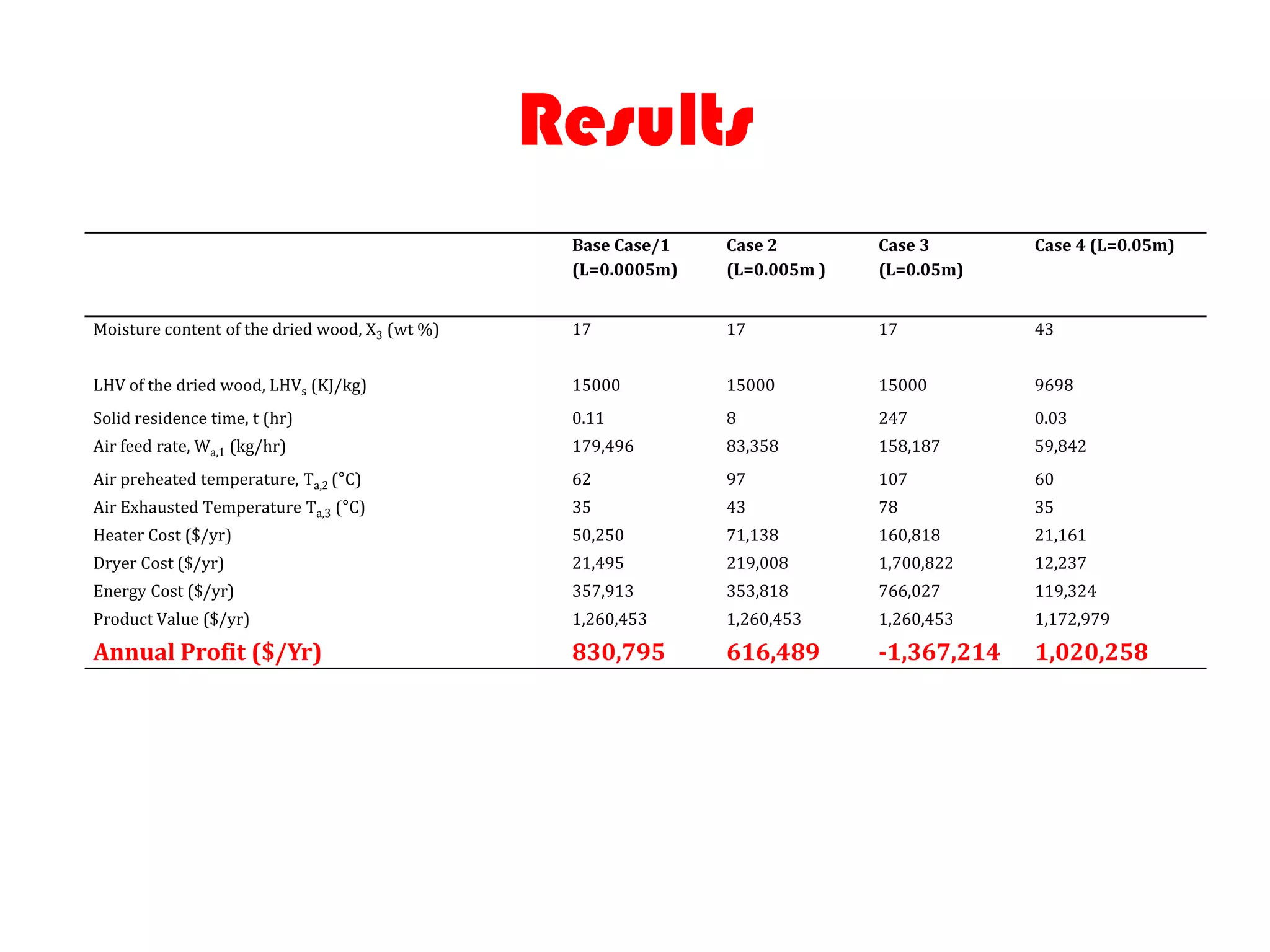

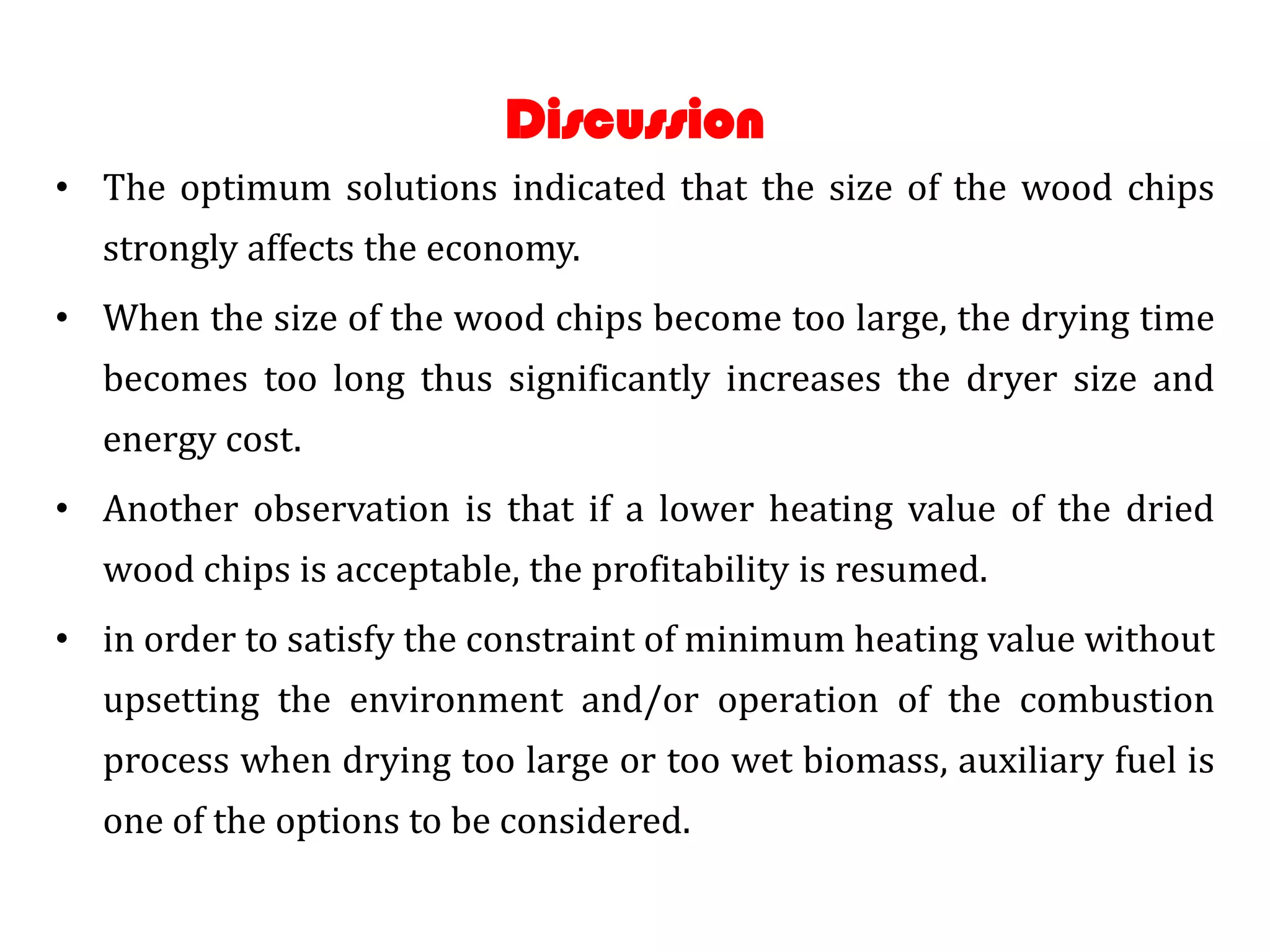

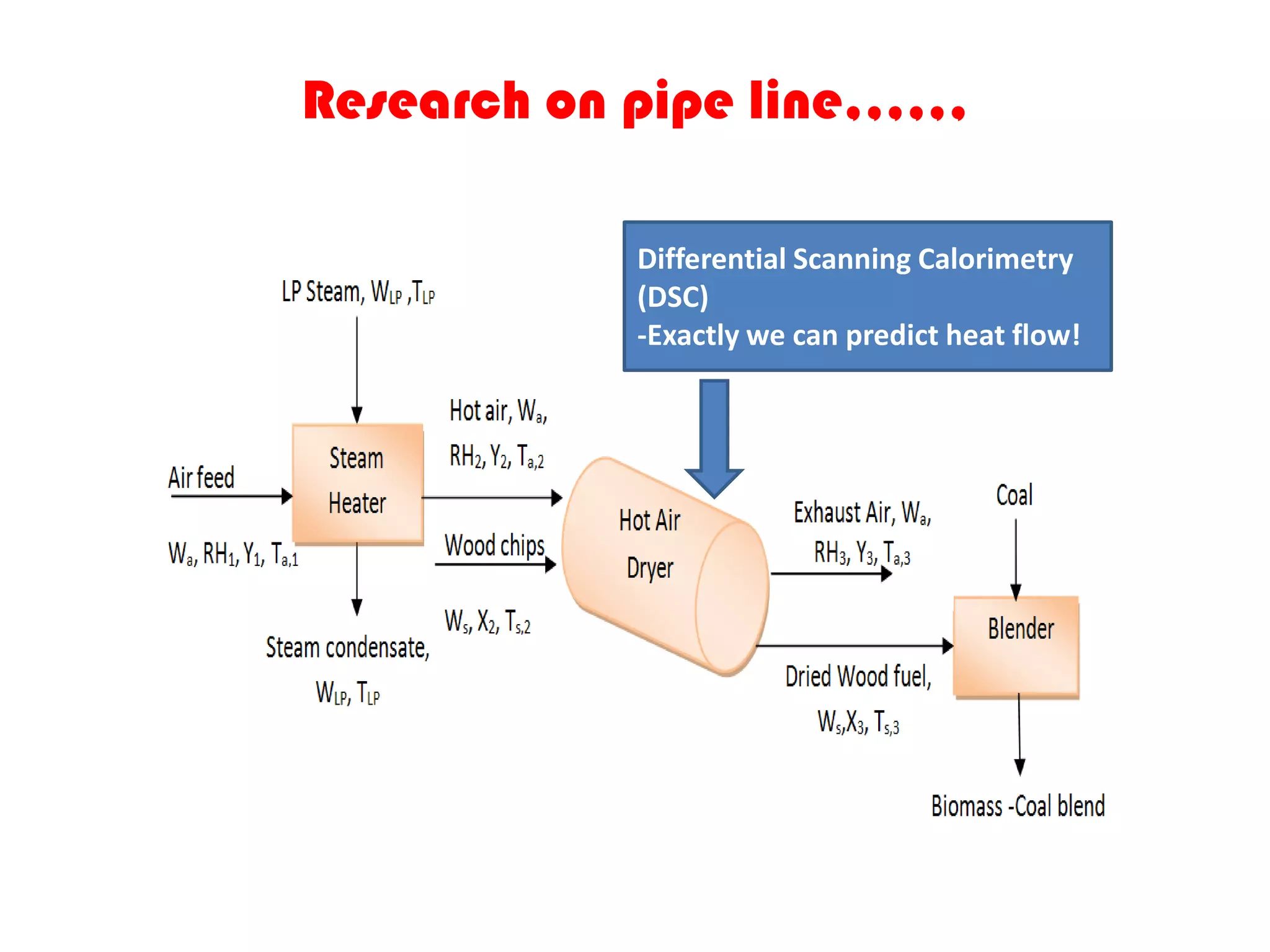

This document summarizes a seminar on optimizing biomass drying for combustion. [1] Biomass comes from various sources like wood, waste, and algae and is dried to increase its heating value before combustion. [2] A model was developed to analyze drying kinetics and optimize drying time, rate, energy needs. [3] Experiments using thermogravimetric analysis characterized wood drying and the model was used to evaluate design parameters and maximize annual profit from a drying process.