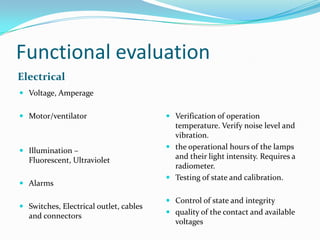

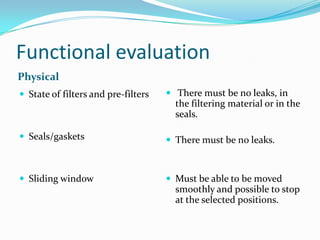

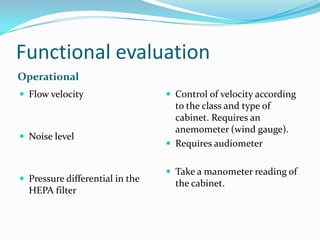

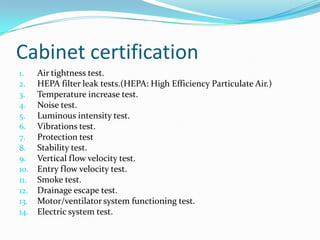

The document provides an overview of biological safety cabinets, their purpose in protecting workers, samples, and the environment from infectious materials. It details the design, operational theory, types, installation requirements, maintenance procedures, and functional evaluations needed for safety cabinets. Additionally, it outlines certification tests necessary to ensure proper functioning and safety standards.