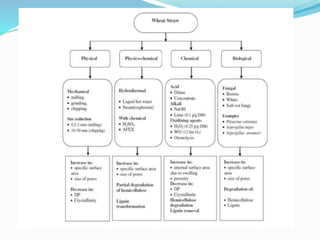

This document discusses the production of bioethanol from wheat straw. It begins with an introduction to bioethanol and its properties. It then discusses that wheat straw is a promising lignocellulosic material for bioethanol production due to its global abundance. The production of wheat straw is outlined, noting that over 430 million tonnes are produced annually. The key steps to produce bioethanol from wheat straw are pretreatment to break down the lignocellulose structure, hydrolysis to release sugars, fermentation of the sugars to ethanol, and distillation to recover the ethanol. When these steps were tested on wheat straw, a bioethanol yield of up to 19% was achieved.