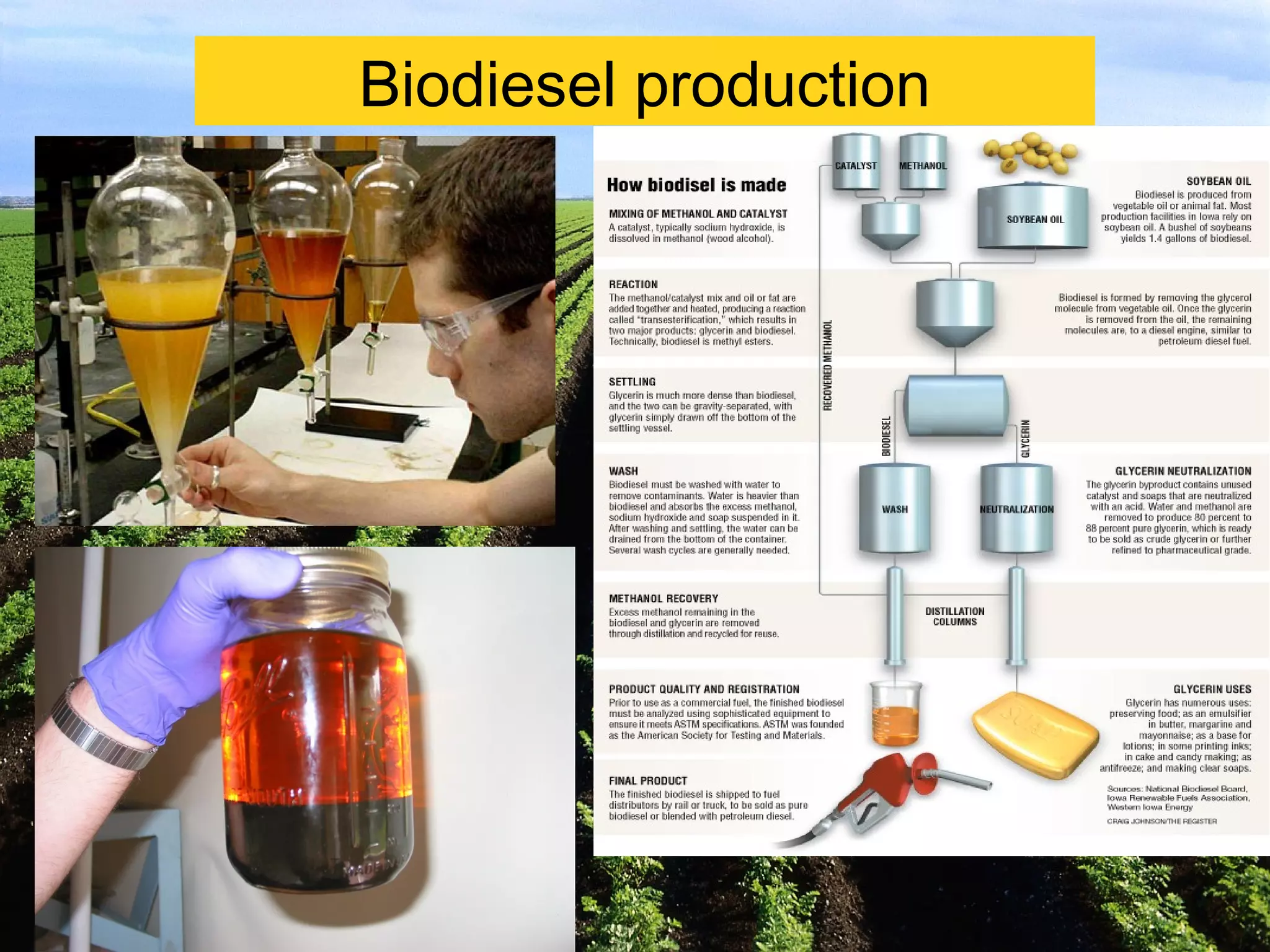

The biodiesel production process involves several steps: (1) extracting oil from rapeseed through pressing, (2) preparing the oil and catalyst for transesterification, (3) performing transesterification where rapeseed oil reacts with methanol in the presence of a catalyst to form biodiesel and glycerin, (4) separating the biodiesel and glycerin, and (5) filtering and cleaning the biodiesel. Transesterification converts the glycerol in vegetable oils into methanol which produces biodiesel. The advantages of biodiesel include reduced emissions, biodegradability, and similar engine performance as petrodiesel. However, biodiesel may contain acrole