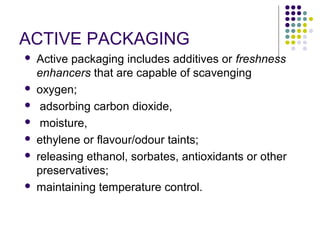

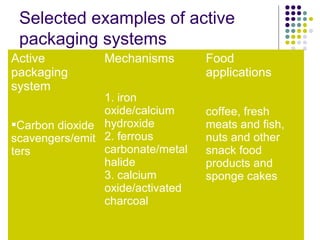

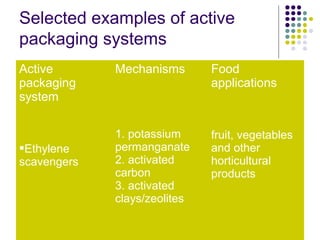

This document discusses biodegradable active packaging. It begins by defining biodegradable packaging and describing common materials used, such as plant oils, cellulose and starches. It then explains that active packaging incorporates additives to maintain or extend product shelf life beyond providing a barrier. Examples of active systems given are oxygen, carbon dioxide and ethylene scavengers, as well as ethanol emitters. The document concludes that active packaging can help maintain food quality and extend shelf life while ensuring safety.