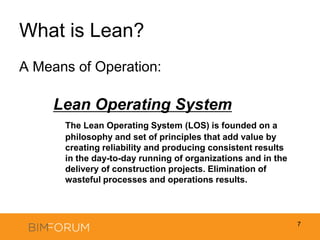

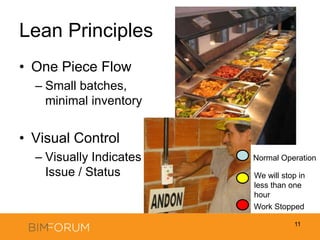

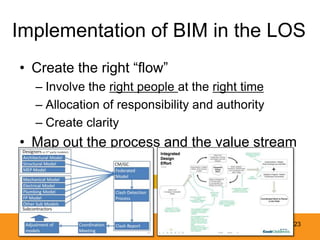

The document discusses the integration of Building Information Modeling (BIM) within a Lean Operating System, highlighting the motivations, principles, and implementation strategies for using BIM effectively. It emphasizes that effective BIM relies heavily on lean principles to eliminate waste, enhance communication, and improve stakeholder collaboration throughout construction processes. The conclusion states that the value of BIM significantly increases when applied within the framework of lean methodologies.