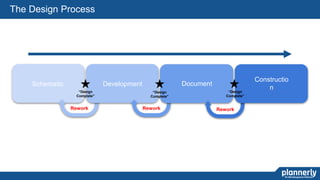

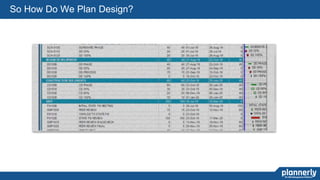

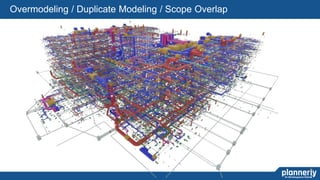

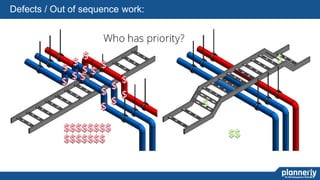

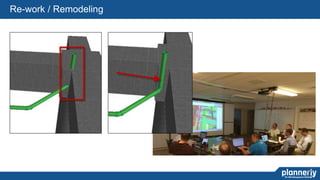

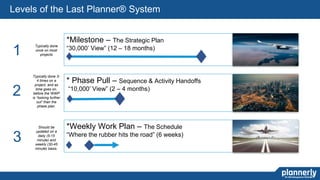

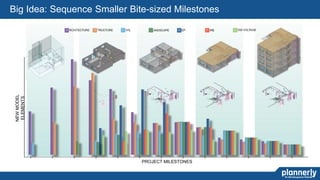

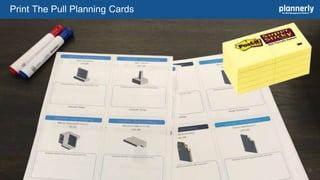

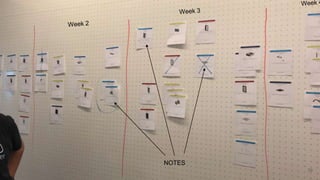

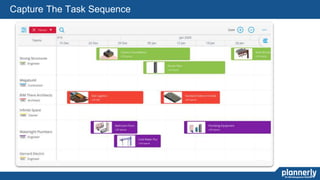

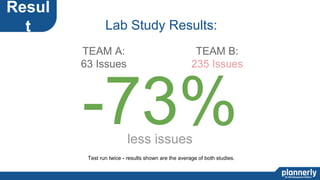

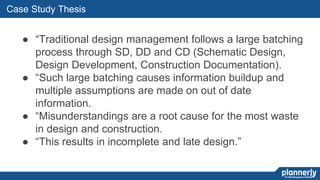

The document discusses lean design in the context of Building Information Modeling (BIM), identifying six primary wastes and providing planning methodologies such as phase planning and weekly work planning. It emphasizes the importance of minimizing waste while maximizing customer value and offers practical tips for implementing lean BIM practices. The document also includes examples of success in project completion times and quality improvements through better management strategies.