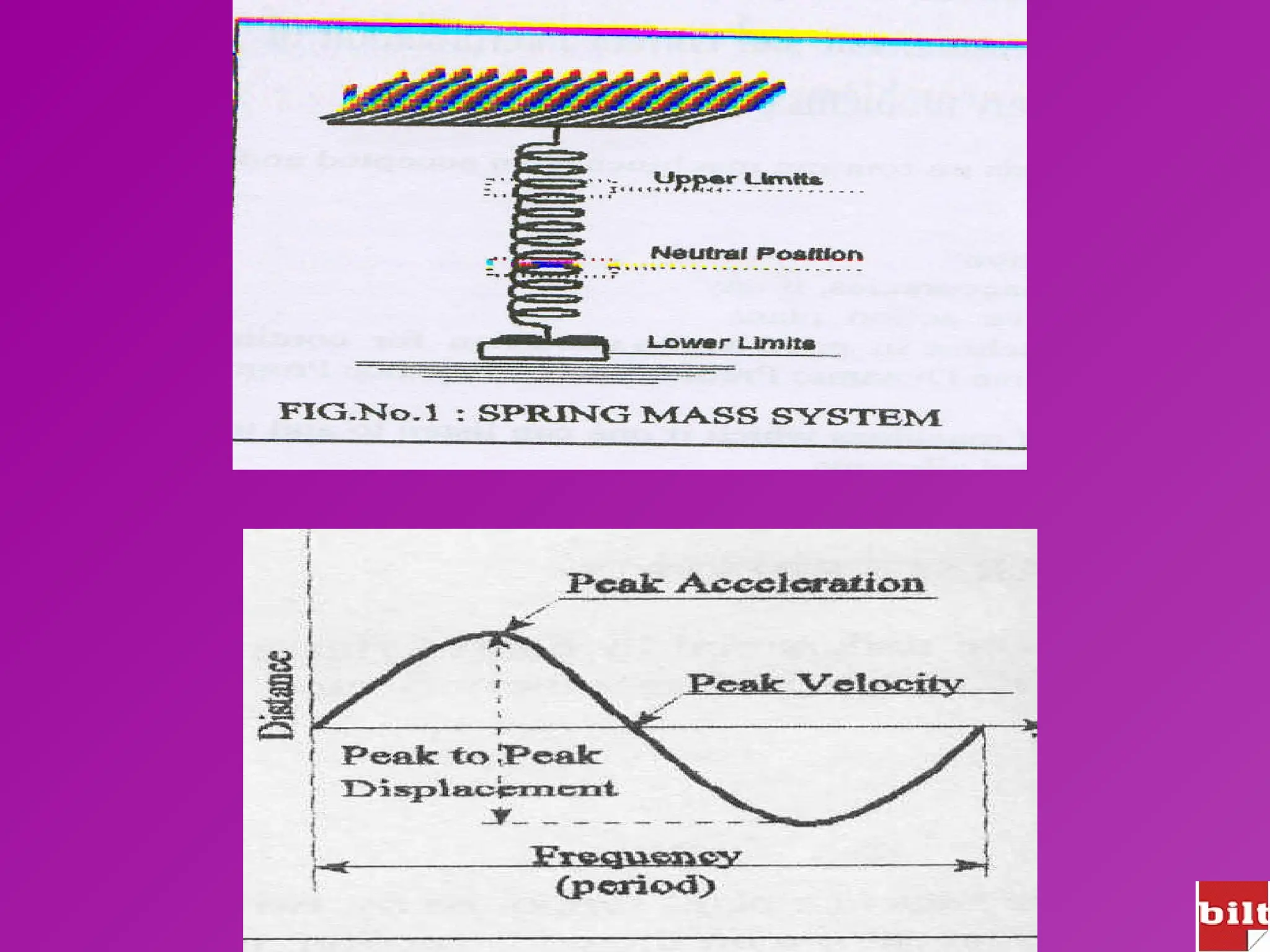

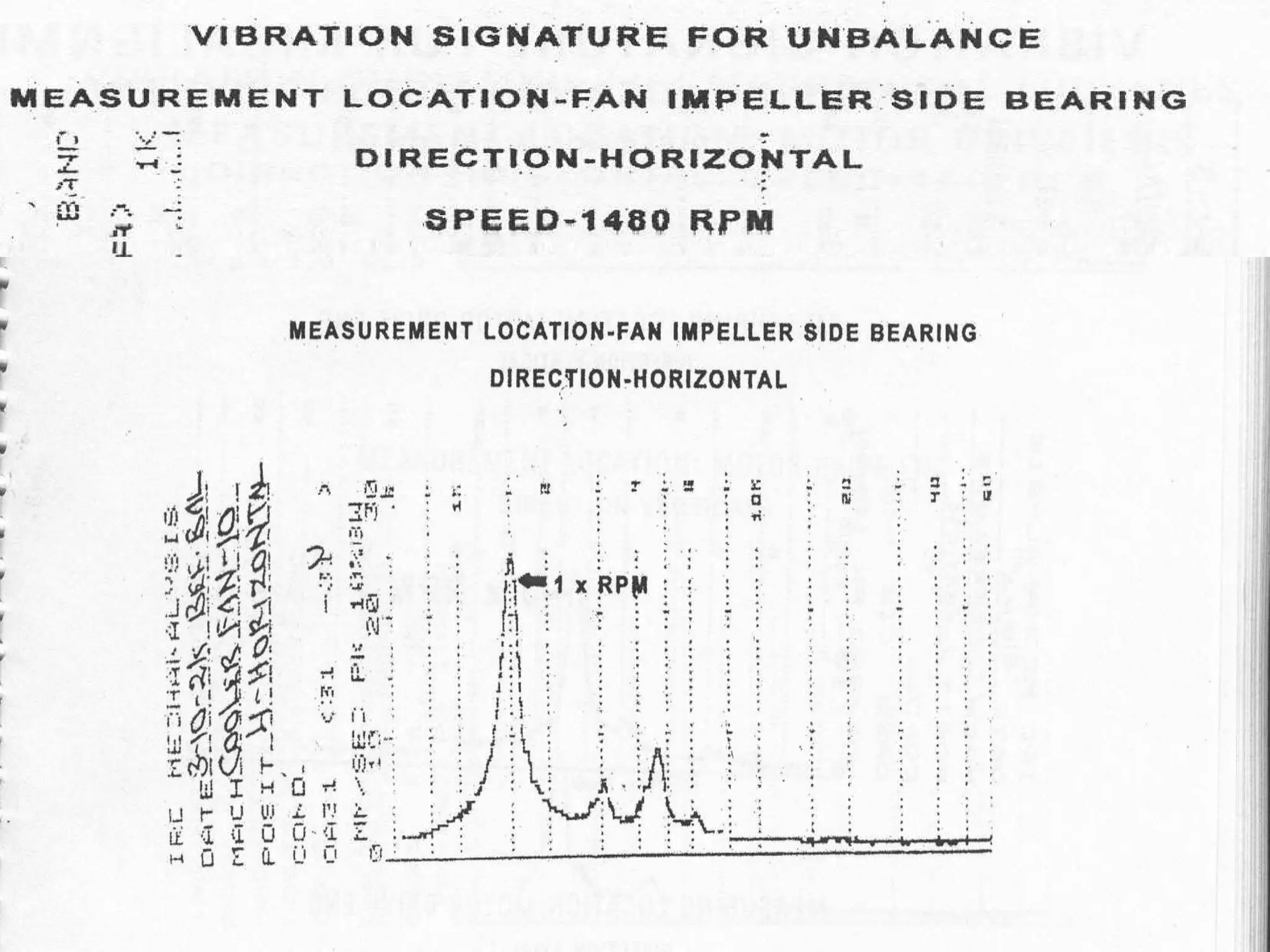

The document presents an in-depth overview of vibration analysis, highlighting its importance in diagnosing machinery health and improving maintenance practices. It covers key concepts such as vibration characteristics, common machinery problems, and methods for addressing issues like unbalance, misalignment, and resonance. Lastly, it provides general maintenance tips to ensure optimal machine operation and longevity.