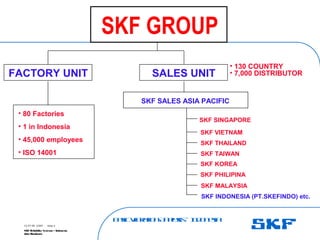

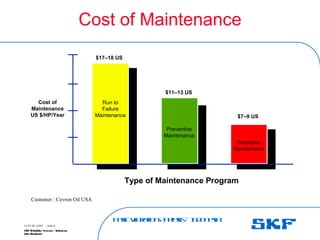

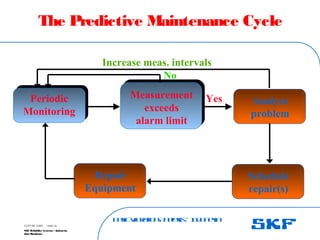

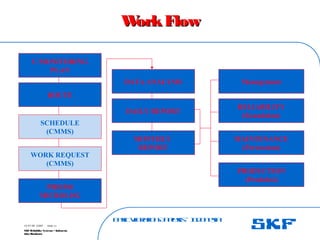

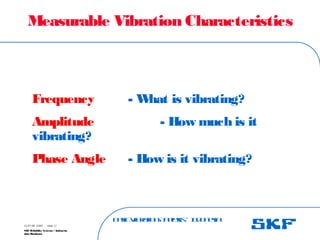

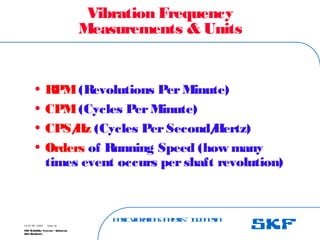

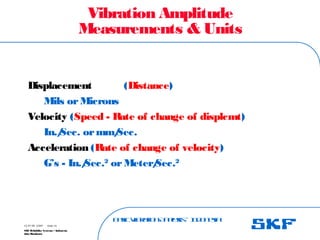

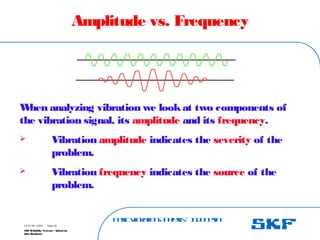

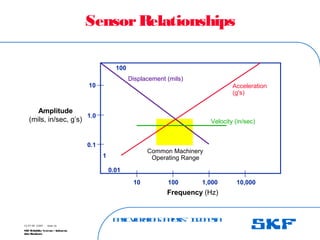

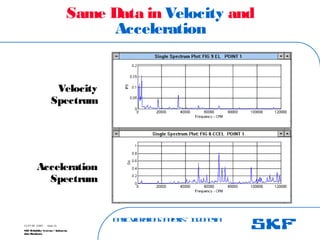

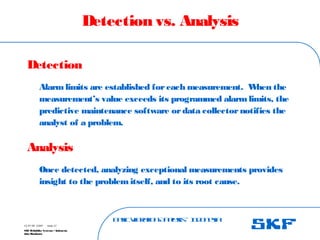

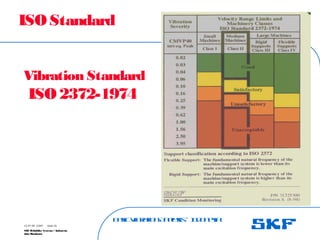

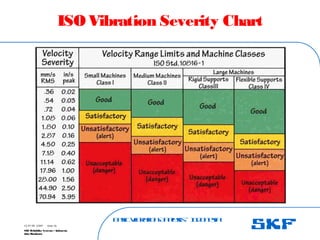

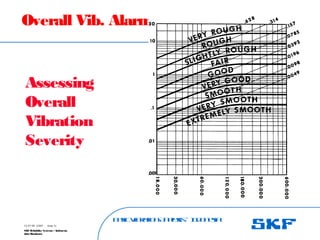

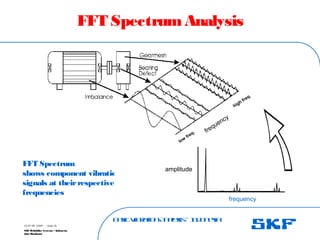

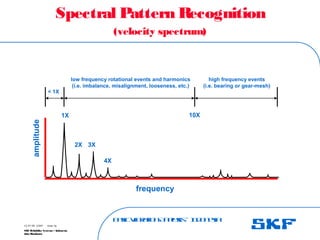

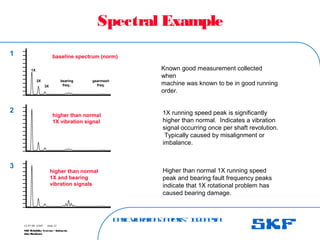

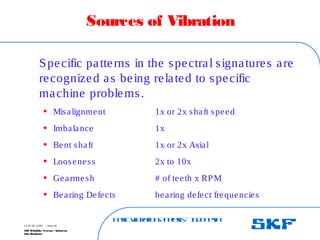

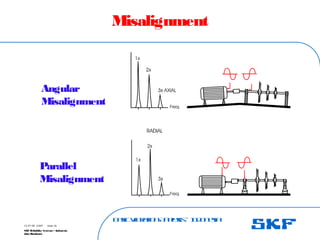

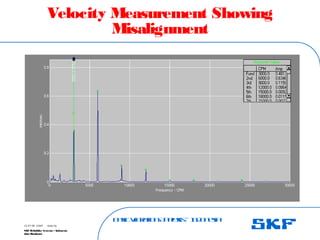

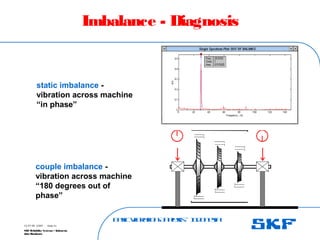

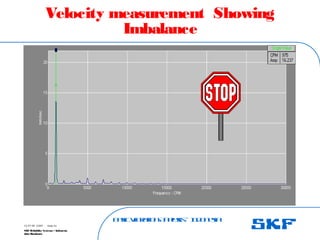

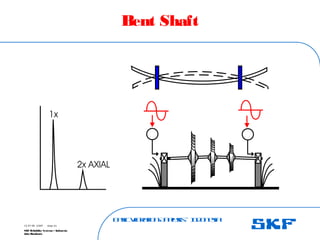

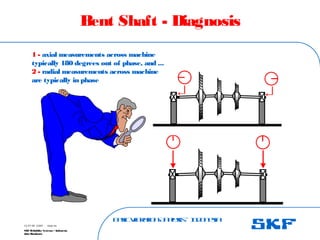

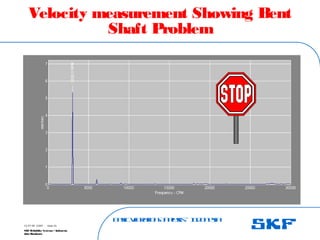

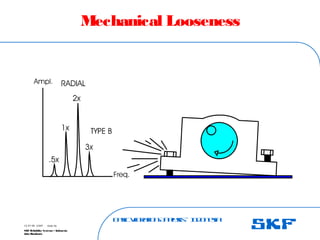

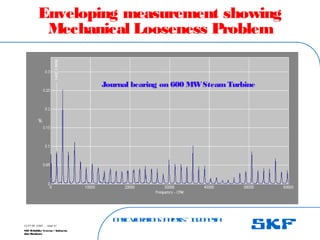

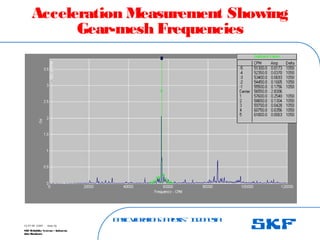

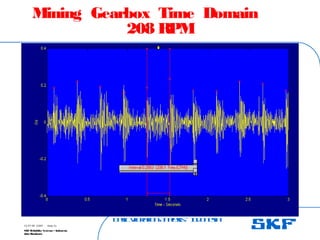

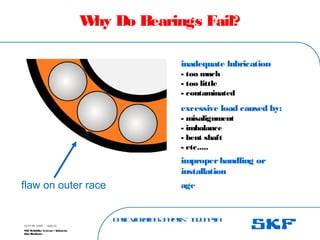

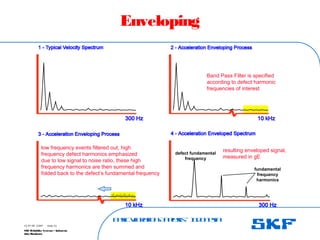

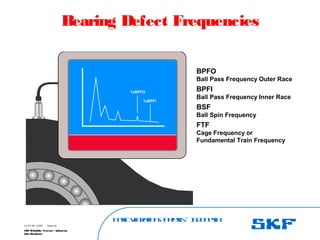

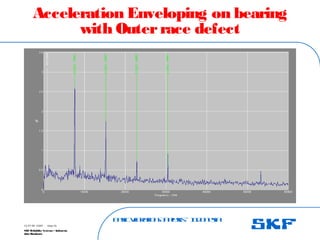

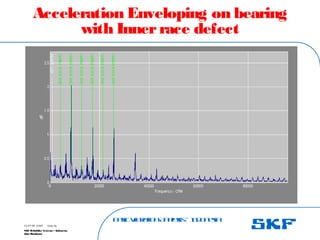

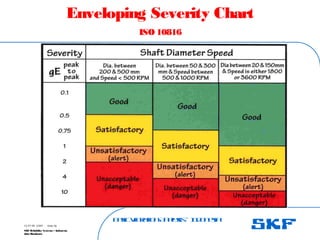

The document is a presentation by SKF Reliability Systems on vibration analysis conducted in Indonesia. It discusses SKF's reliability services, predictive maintenance practices using vibration monitoring, and basic vibration analysis techniques. The presentation covers SKF's network and philosophy, predictive maintenance workflows and measurements, vibration data collection methods, and alarm setting and ISO standards for vibration analysis.