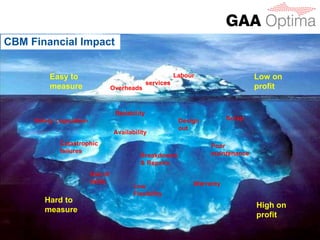

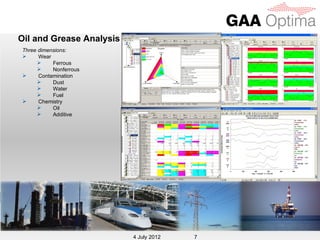

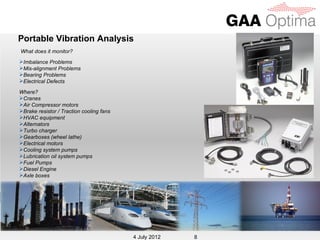

This document introduces condition-based maintenance (CBM), which uses condition monitoring technologies to predict asset failures and schedule maintenance based on equipment condition rather than time. CBM aims to improve operating performance, ensure safety and environmental protection, reduce maintenance costs, and provide a comprehensive maintenance database. The CBM methodology takes a two-level approach using technologies to identify short-term failures and reduce medium to long-term maintenance tasks. CBM technologies discussed include oil and grease analysis, portable vibration analysis, portable ultrasonic analysis, and portable thermography analysis to monitor various mechanical and electrical equipment conditions.