Liquid membranes can be either immobilized liquid membranes (ILM), also called supported liquid membranes (SLM), or emulsion liquid membranes (ELM). ILMs are made by immersing a thin porous solid film with a liquid, allowing molecules to diffuse through the liquid in the pores. ELMs contain small liquid globules of one liquid suspended in another liquid medium. Liquid membranes allow separation through passive diffusion, facilitated transport using a carrier molecule, or coupled transport where the carrier couples the flow of two species. Common applications include removal of specific ions, gases, and organic compounds.

![Introduction

• Types of Membranes :

[3]](https://image.slidesharecdn.com/liquidmembrane-170501171547/75/Liquid-membrane-2-2048.jpg)

![Liquid Membrane

• A material for the preparation of a membrane need to be solid only. A

liquid may also act as a separation barrier between two phases or

mediums where the transport occurs by the ‘Solution – diffusion

mechanism ’. [3]

[6]](https://image.slidesharecdn.com/liquidmembrane-170501171547/75/Liquid-membrane-3-2048.jpg)

![(1). Immobilized liquid membrane (ILM) :

• Also Called as Supported liquid membrane(SLM)

• Made by immersing a thin porous film of suitable solid substance with a

liquid.

• Molecules diffuse through the

liquid in the pores.

• Membrane thickness is

20 -150 µm

[3]](https://image.slidesharecdn.com/liquidmembrane-170501171547/75/Liquid-membrane-5-2048.jpg)

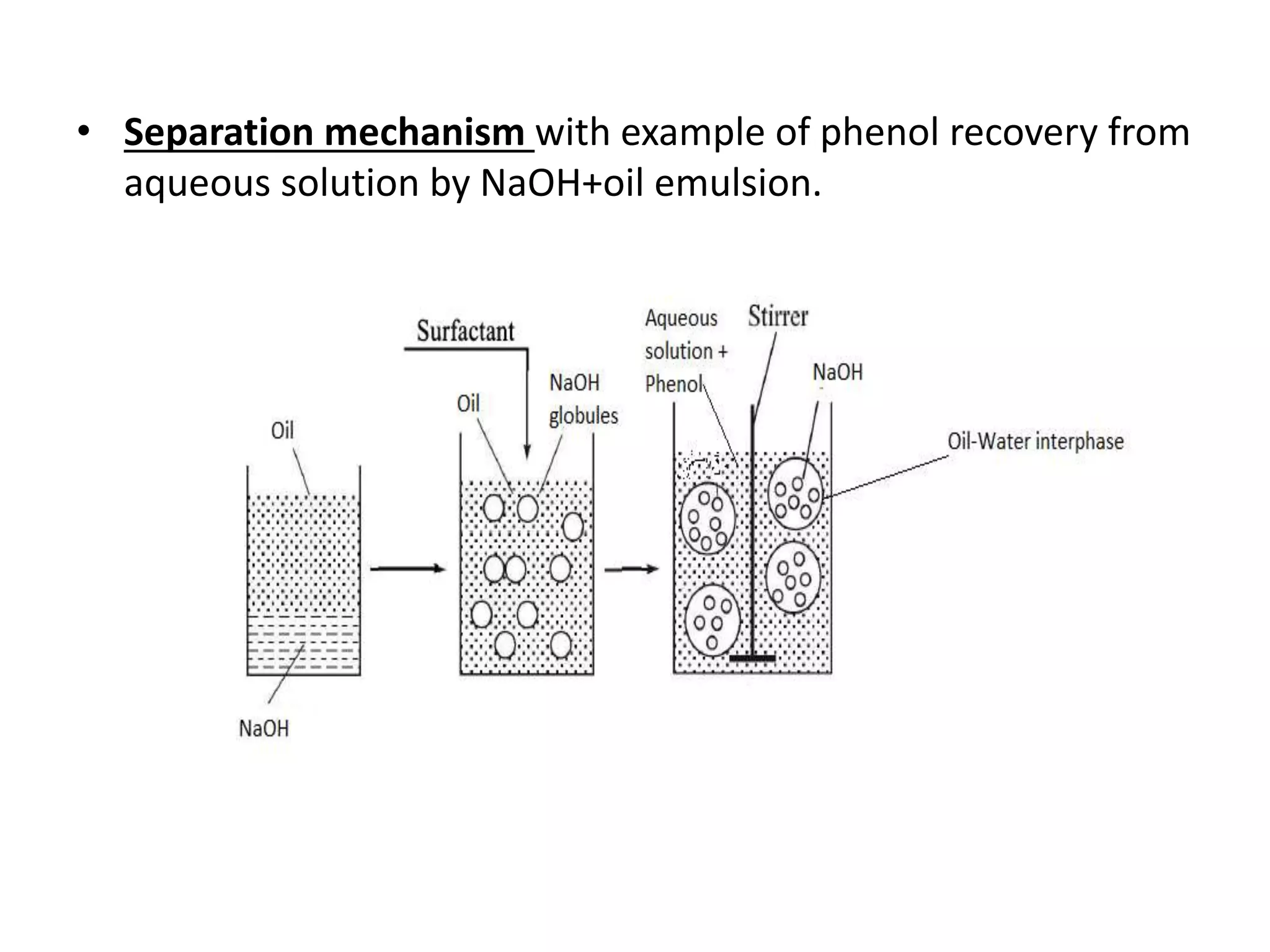

![(2). Emulsion liquid membrane (ELM) :

• An ELM is a liquid droplet which contains number of very small

globules[Droplet - size about 0.5-10 µm] of another liquid within it,

suspended in a liquid medium.

[3]](https://image.slidesharecdn.com/liquidmembrane-170501171547/75/Liquid-membrane-6-2048.jpg)

![• The liquid membranes illustrated here are only used in some specific

applications because of the rather low selectivities which is the

differences in solubility and diffusivity.

• Far higher selectivities can be obtained by adding a carrier molecule to the

liquid (membrane) which has a high affinity for one of the solutes in phase

1.

• The carrier accelerates the transport of this specific component. This type

of transport is called 'carrier-mediated‘ transport or facilitated transport.

[1]](https://image.slidesharecdn.com/liquidmembrane-170501171547/75/Liquid-membrane-8-2048.jpg)

![carrier-mediated transport /

facilitated transport

• When a carrier is present inside the membrane with the ability to complex

with a specific solute the flux of that solute may be enhanced.

• Carrier may be dissolved in the liquid - carrier is mobile.

• Carrier can be bound chemically (covalently) or physically to a solid

polymer - Carrier is fixed and has a very restricted mobility.

[1]](https://image.slidesharecdn.com/liquidmembrane-170501171547/75/Liquid-membrane-9-2048.jpg)

![• Comparison of diffusivities :

System Mechanism D(cm2/s)

Mobile carrier system The carrier-solute complex

diffuses across the

membrane.

10-5 – 10-7

Gel system The carrier-solute complex

diffuses across the

membrane.

10-6 – 10-8

Fixed carrier The solute jumps from one

site to the other.

> 10-7

[1]](https://image.slidesharecdn.com/liquidmembrane-170501171547/75/Liquid-membrane-10-2048.jpg)

![Types of transport mechanism in liquid membrane :

(1). Passive diffusion :

• Passive diffusion dueto concentration gradient.

[2]](https://image.slidesharecdn.com/liquidmembrane-170501171547/75/Liquid-membrane-11-2048.jpg)

![(2). Facilitated transport :

• The liquid membrane phase contains a carrier agent that chemically

combines with the feed solute to be transported.

[2]](https://image.slidesharecdn.com/liquidmembrane-170501171547/75/Liquid-membrane-12-2048.jpg)

![(3). Coupled transport :

• The carrier agent couples the flow of two species. Because of this

coupling, one of the species can be moved against its concentration

gradient, provided the concentration gradient of the second coupled

species is sufficiently large.

[2]](https://image.slidesharecdn.com/liquidmembrane-170501171547/75/Liquid-membrane-13-2048.jpg)

![Preparation technique Materials

Stretching Polypropylene

polytetrafluoroethylene

Phase inversion Polypropylene

polyethylene

• Materials used for support membrane :

[1]](https://image.slidesharecdn.com/liquidmembrane-170501171547/75/Liquid-membrane-15-2048.jpg)

![ii. Choice of Organic Solvent :

The organic liquid must be a solvent for both the carrier and the carrier-

solute complex.

Another important factor is the viscosity of the organic phase.

On increasing the carrier concentration, two effects are counteracting.

↑ CC → ↑ Entering flux

↑ CC → ↑ Viscosity → ↓ diffusion coefficient → ↓ diffusion flux

[1]](https://image.slidesharecdn.com/liquidmembrane-170501171547/75/Liquid-membrane-16-2048.jpg)

![• Some solvents used in Liquid Membrane :

Solvents Viscosity (T=298 K) g.cm-1.s-1

o-dichlorobenzene 0.013

1-octanol 0.076

dibutylphthalate 0.154

o-nitrophenyl octyl ether 0.128

o-nitro diphenylether 0.161

[1]](https://image.slidesharecdn.com/liquidmembrane-170501171547/75/Liquid-membrane-17-2048.jpg)

![ It is essential for the solubility of the organic phase in the aqueous phase

to be as low as possible.

Even if the solubility meets this requirement, after a finite period of time

process will become unstable.

Emulsification of organic phase [1]](https://image.slidesharecdn.com/liquidmembrane-170501171547/75/Liquid-membrane-18-2048.jpg)

![ One approach to solve these problems is by gelantion of the liquid

membrane phase.

This means that the liquid film has the properties of a highly swollen

crosslinked polymer (a 'gel') rather than that of a liquid.

Although the diffusion coefficient will be lower in a gel phase compared to

the liquid but the stability of the layer will have been improved.

Polymers which are useful in this process are :

poly vinyl chloride(PVC),

poly acrylonitrile (PAN) and

poly methylmethacrylate (PMMA).

[1]](https://image.slidesharecdn.com/liquidmembrane-170501171547/75/Liquid-membrane-19-2048.jpg)

![iii. Choice of carrier :

High selectivities are obtained if the carrier is very specific to one solute.

Here are some class of carrier molecules mentioned :

oximes (tertiary),

amines,

crown ethers,

cobalt complexes.

[1]](https://image.slidesharecdn.com/liquidmembrane-170501171547/75/Liquid-membrane-20-2048.jpg)

![Applications

• Removal of specific ions

-cations (cadmium, copper, nickel, lead)

-anions (nitrate, chromate)

• Removal of gases

-oxygen/nitrogen separation

-removal of H2S, C02, S02, CO, NH3

• Separation of organic liquids

• Removal of phenol [1]](https://image.slidesharecdn.com/liquidmembrane-170501171547/75/Liquid-membrane-21-2048.jpg)

![Advantages

• Uphill Transport Characteristic

• High Interfacial Area per Unit Volume

• Low Solvent Loss

• Low possibilities of concentration polarization [5]](https://image.slidesharecdn.com/liquidmembrane-170501171547/75/Liquid-membrane-22-2048.jpg)

![Disadvantages

SLM

• Instability of liquid film.

• Resistance due to membrane itself.

ELM

• Anything effecting emulsion stability must be controlled, i.e. ionic

strengths, pH, etc.

• If, for any reason, the membrane does not remain intact during operation,

the separation achieved to that point is destroyed.

• In order to recover the receiving phase we have to broke down the

emulsion. Since in order to make stable emulsion we have to work against

the ease of breaking it back down.

[5]

[4]](https://image.slidesharecdn.com/liquidmembrane-170501171547/75/Liquid-membrane-23-2048.jpg)