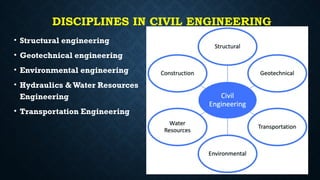

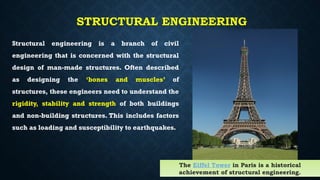

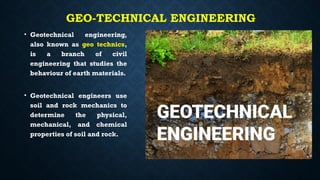

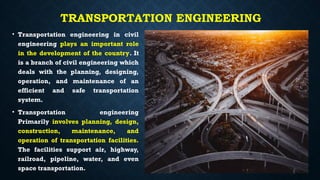

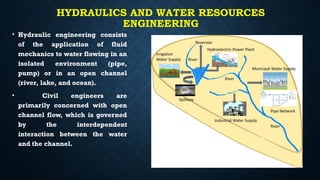

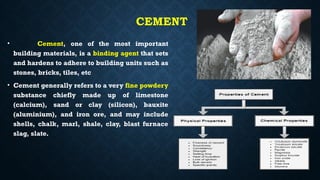

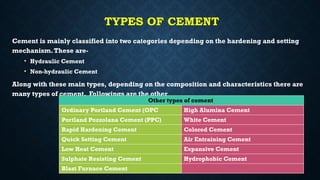

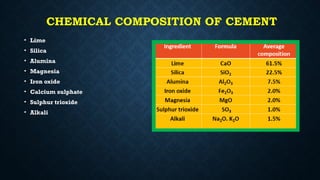

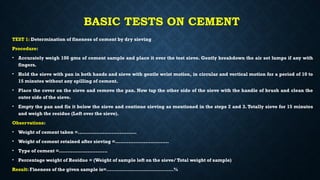

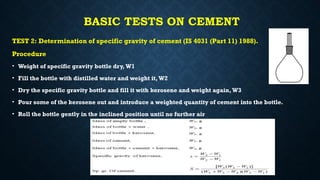

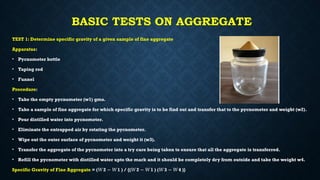

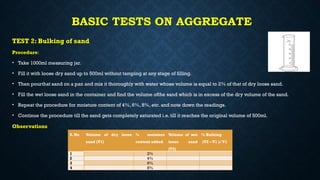

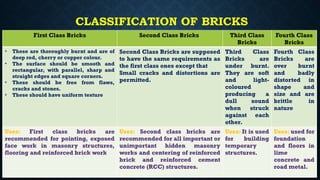

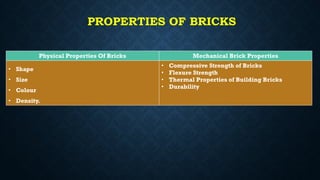

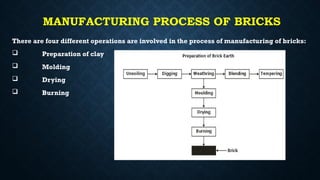

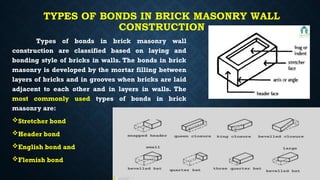

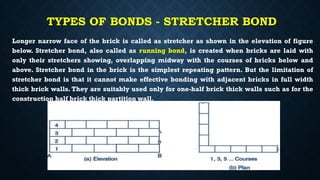

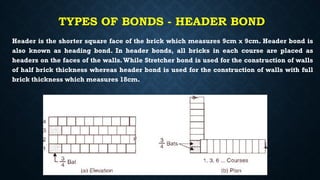

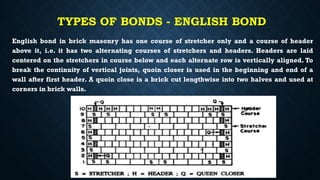

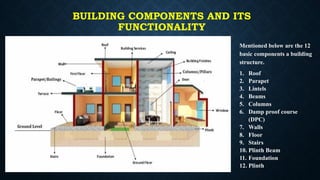

The document outlines the basics of civil engineering, detailing various disciplines such as structural, geotechnical, transportation, hydraulic, and environmental engineering. It describes the roles of civil engineers, including planning, designing, and supervising structures, as well as the materials used in construction like cement, aggregates, and bricks. Additionally, it covers essential engineering concepts related to construction materials and techniques, alongside the significance of civil engineering in society.