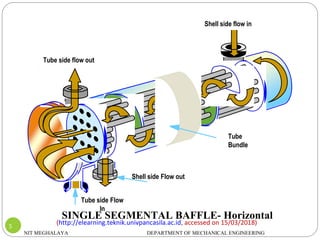

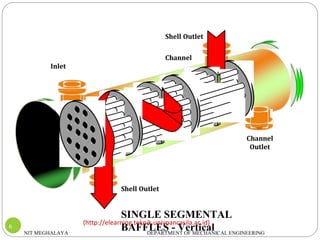

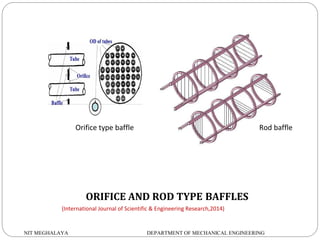

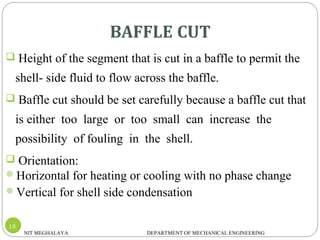

This document discusses baffles in shell and tube heat exchangers. It begins with an introduction that defines baffles as diverting flow across tube bundles to improve heat transfer and provide structural support to tubes. It then describes the main types of baffles as segmental, orifice, disc and doughnut, and rod baffles. The document also discusses baffle cuts, spacing, and the aims of thermal design, and provides references for further information.