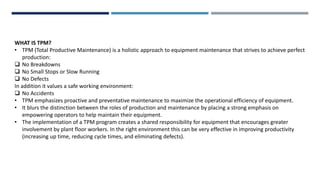

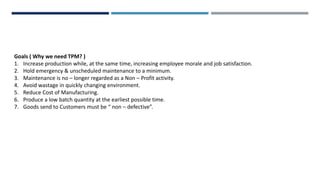

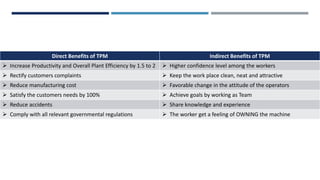

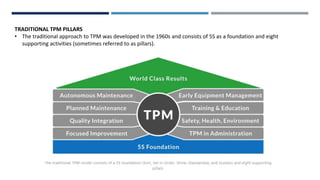

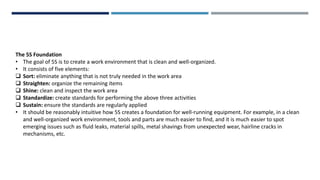

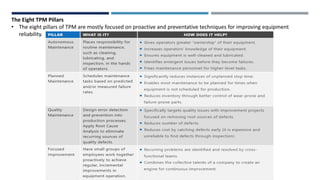

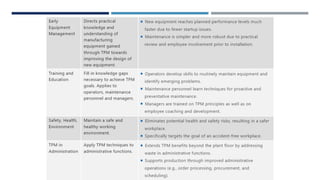

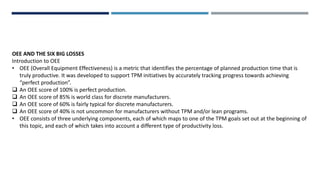

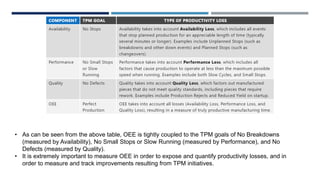

This document provides an introduction to total productive maintenance (TPM) and terotechnology. It defines TPM as a holistic approach to equipment maintenance that aims for perfect production with no breakdowns, small stops, slow running, or defects, while also promoting workplace safety. The goals of TPM include increasing production and employee satisfaction while reducing costs. It emphasizes proactive and preventative maintenance through techniques like 5S and the eight pillars. The document also introduces overall equipment effectiveness (OEE) and its use in measuring productivity losses from the six big losses to track TPM progress. Finally, it defines terotechnology as the technology of efficient equipment installation, use, and maintenance to reduce costs and increase productivity over the lifecycle of equipment