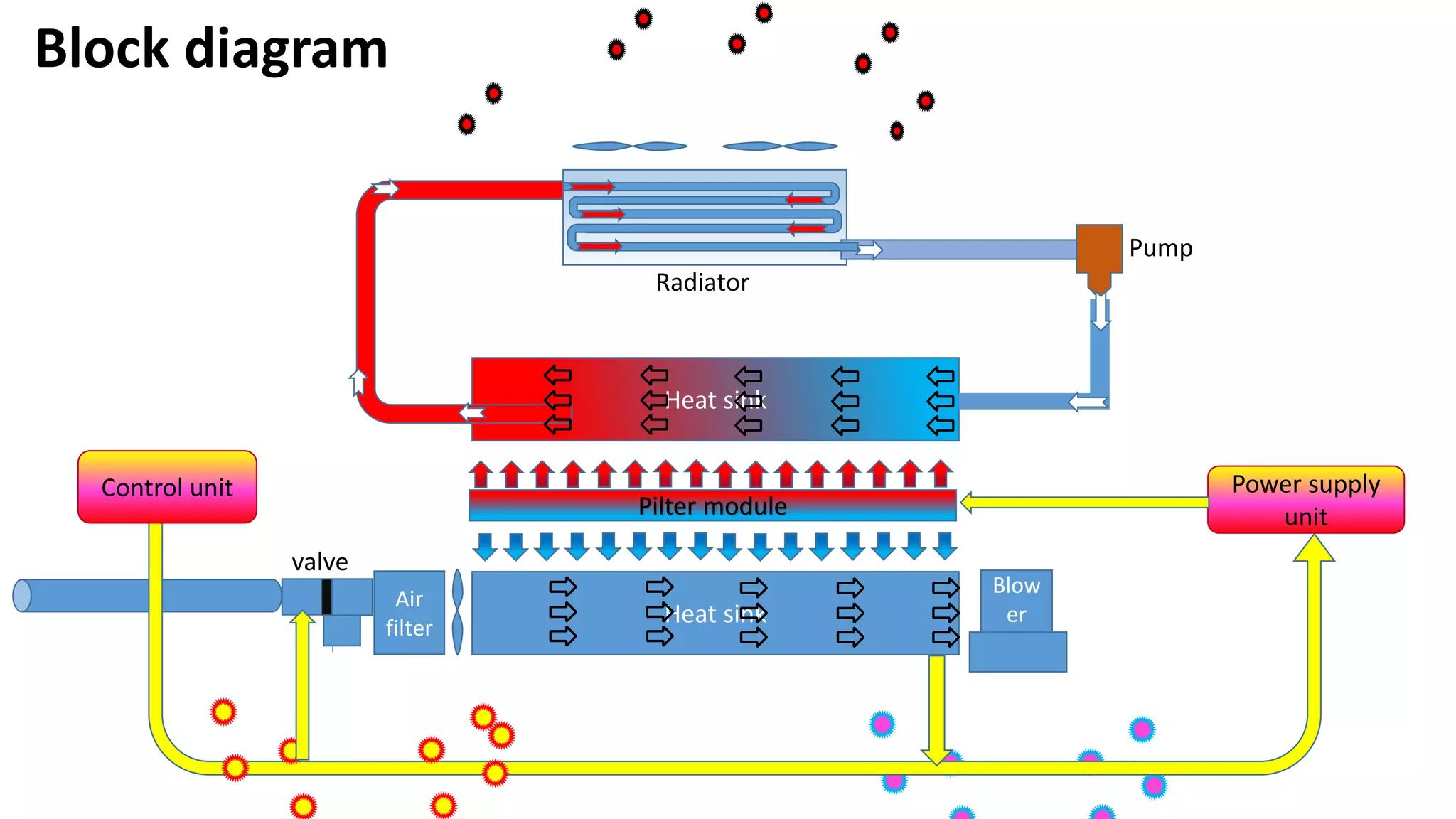

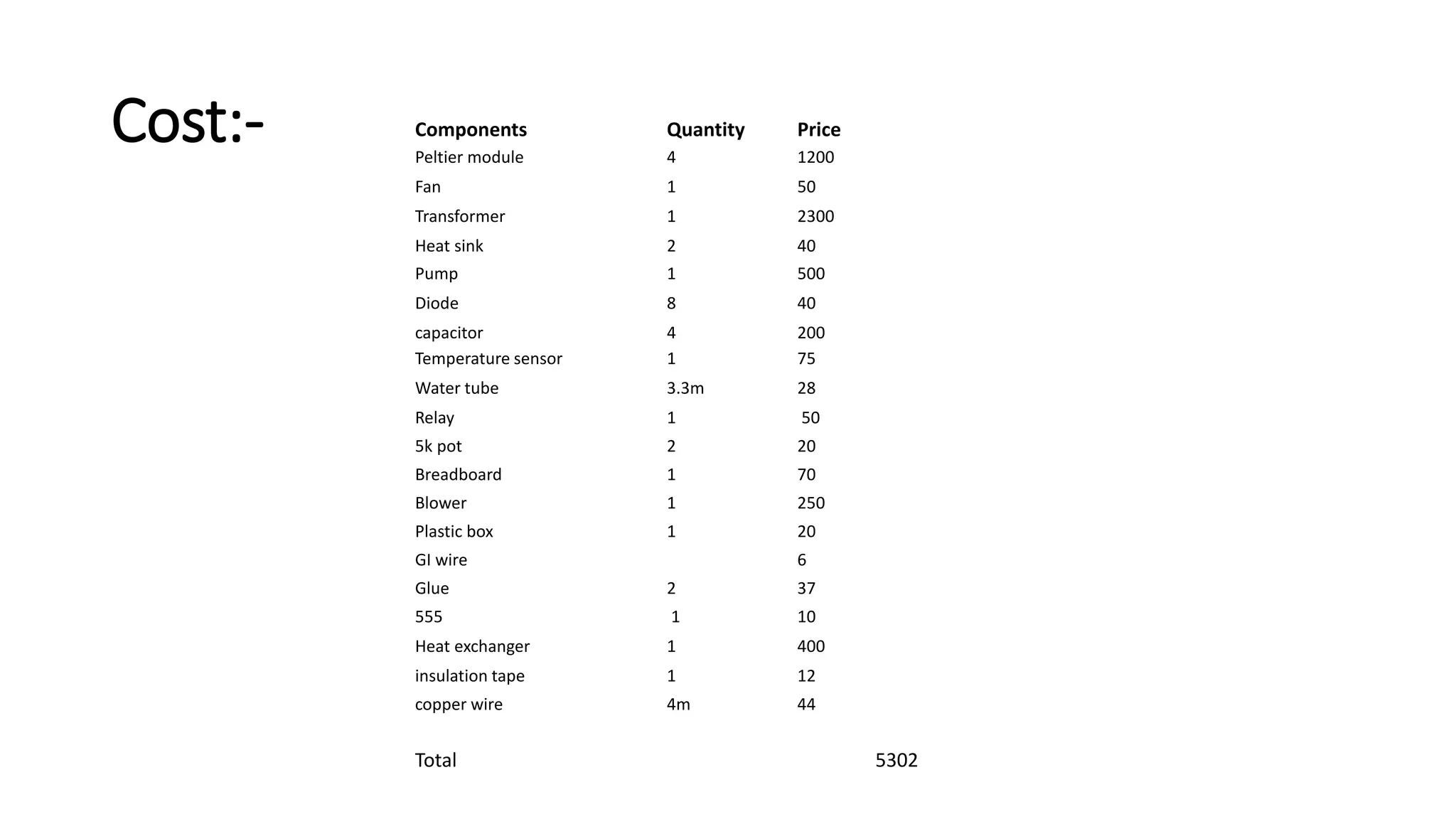

The document outlines the design and construction of an electronic air cooler utilizing a Peltier module for heat exchange, aiming to create a portable and pollution-free cooling system. It includes details on components such as heat sinks, fans, a water cooling system, and a control unit using Arduino, along with advantages like small size, portability, and environmental friendliness due to the absence of harmful refrigerants. However, it notes the requirement for an additional water cooling system and an external power supply for the Peltier module as drawbacks.