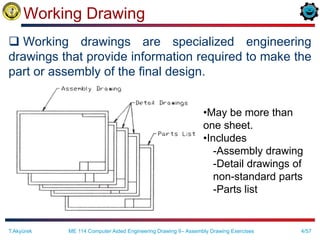

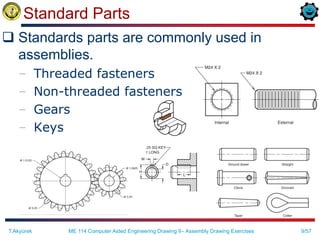

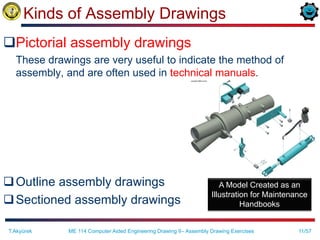

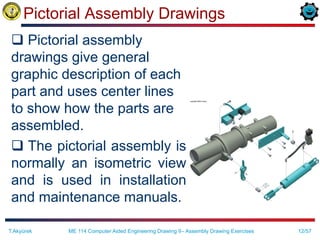

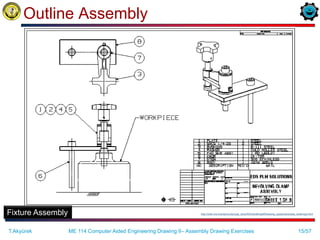

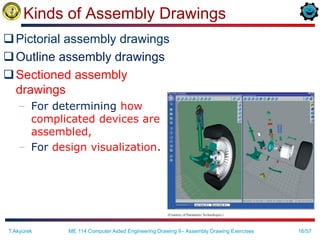

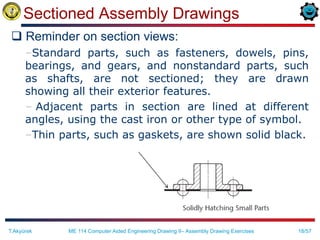

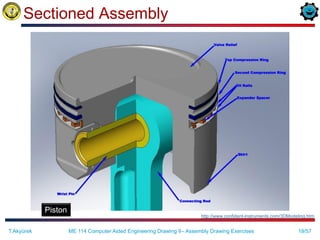

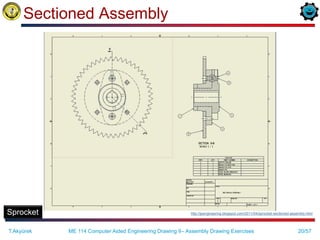

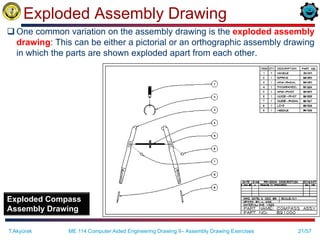

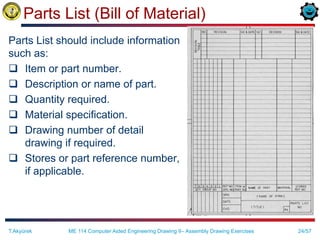

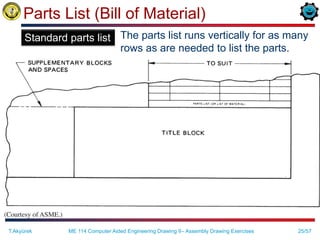

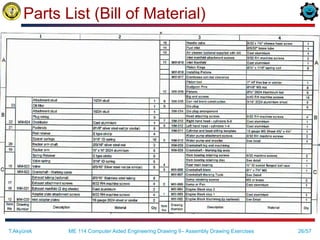

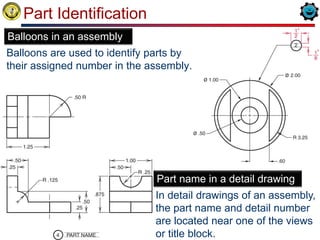

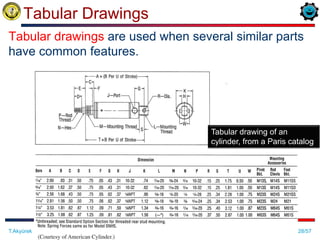

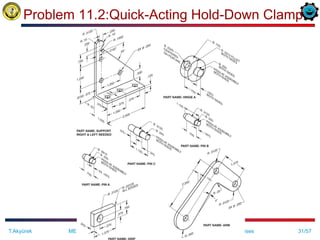

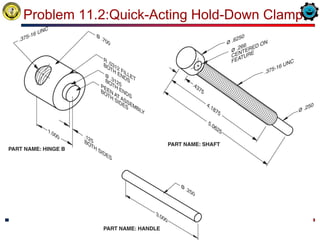

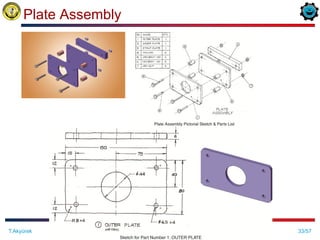

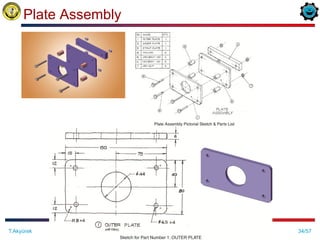

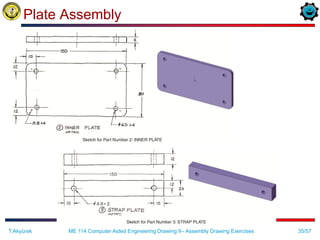

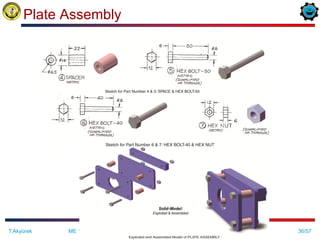

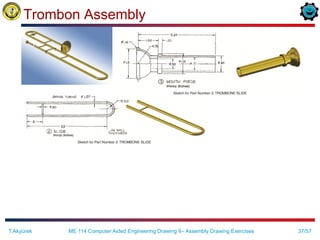

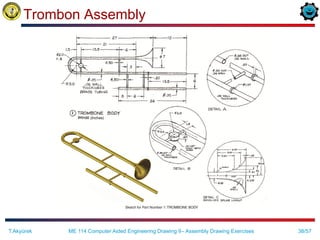

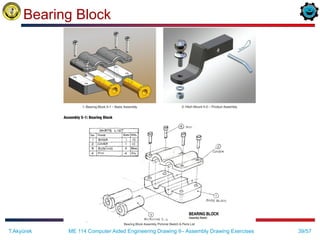

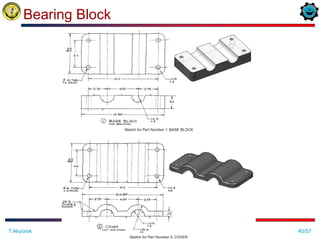

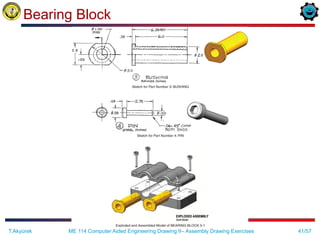

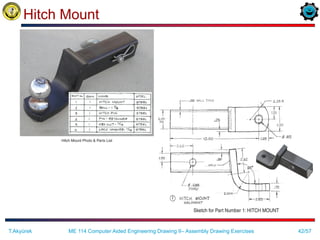

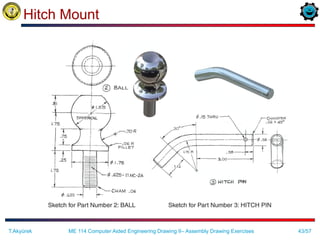

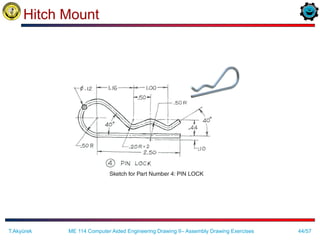

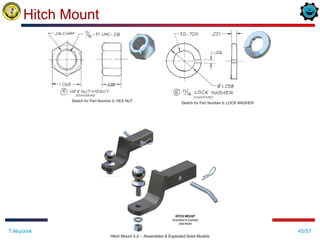

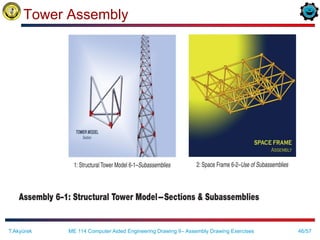

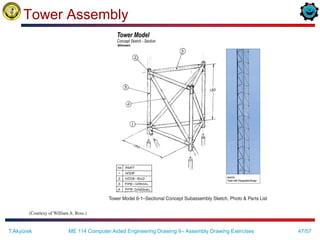

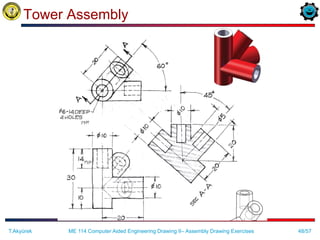

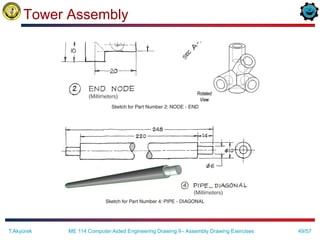

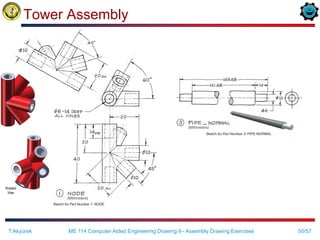

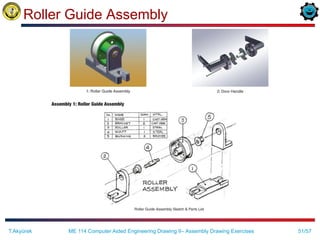

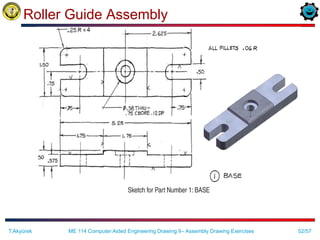

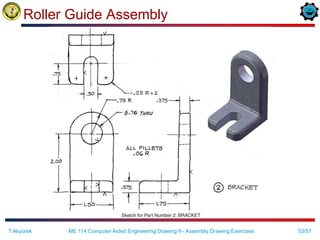

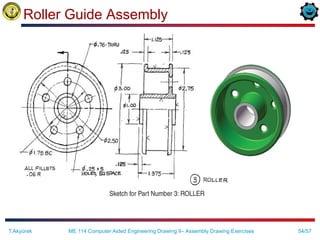

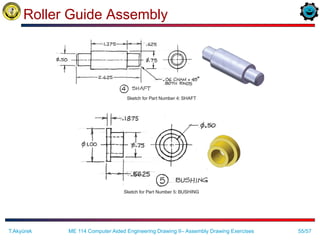

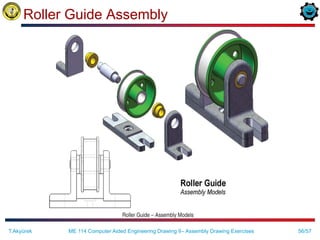

The document provides information on creating assembly drawings, including defining the different types of assembly drawings (pictorial, outline, sectioned), how to construct an assembly, the typical content and components of assembly drawings (such as parts lists, balloons, dimensions), and examples of assembly drawings. It also discusses standard parts, exploded views, and how to identify individual parts in an assembly drawing.