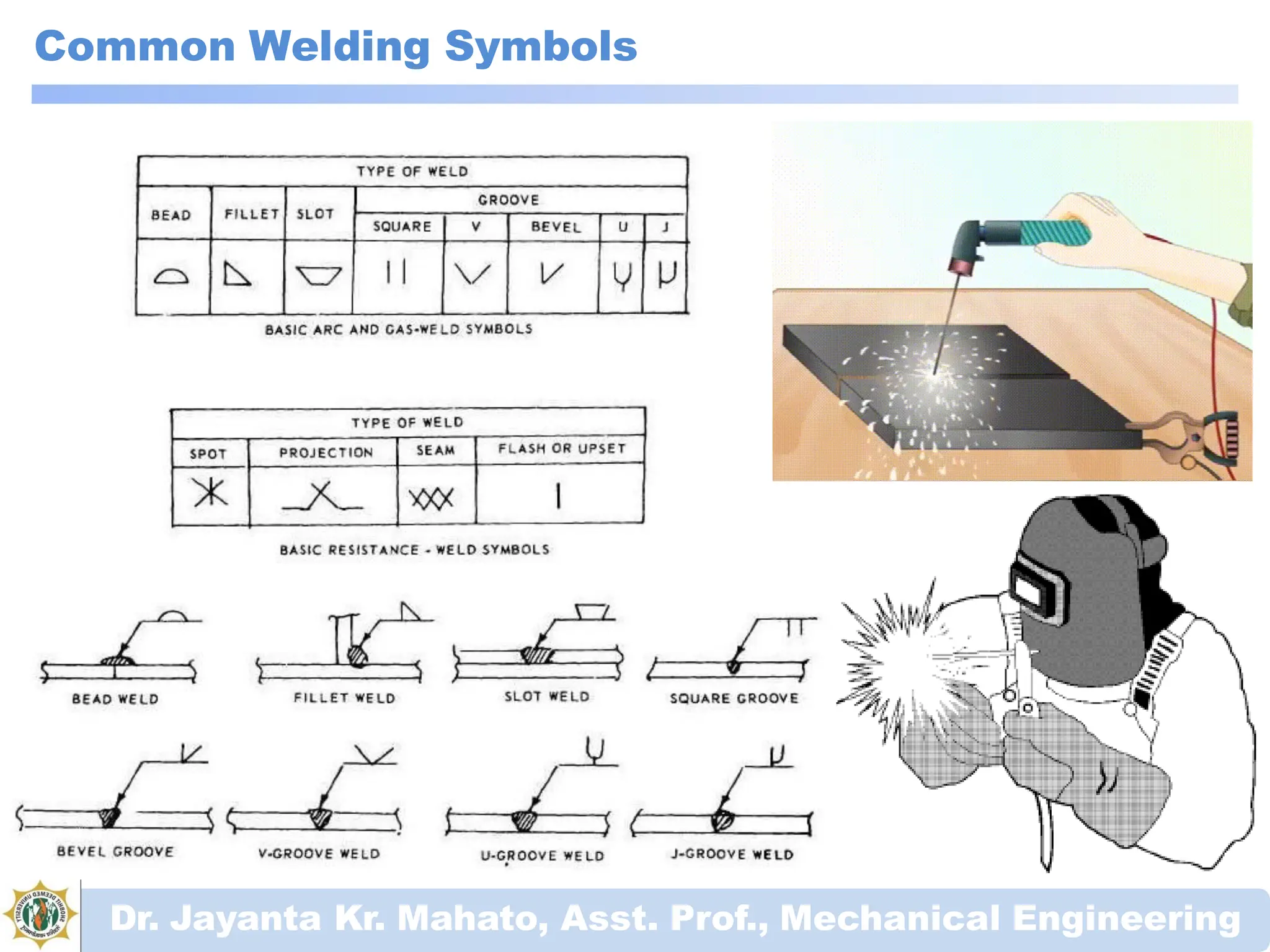

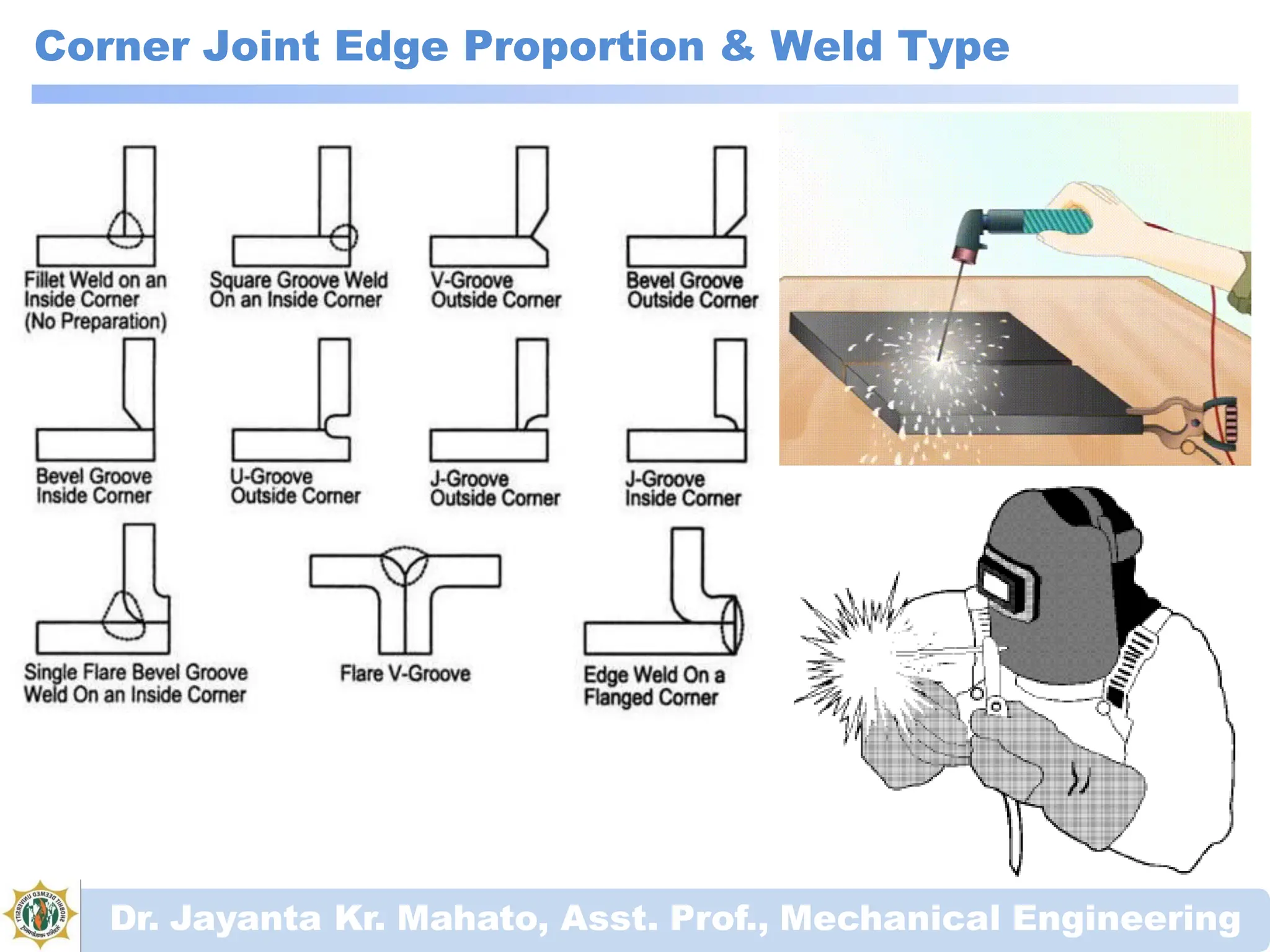

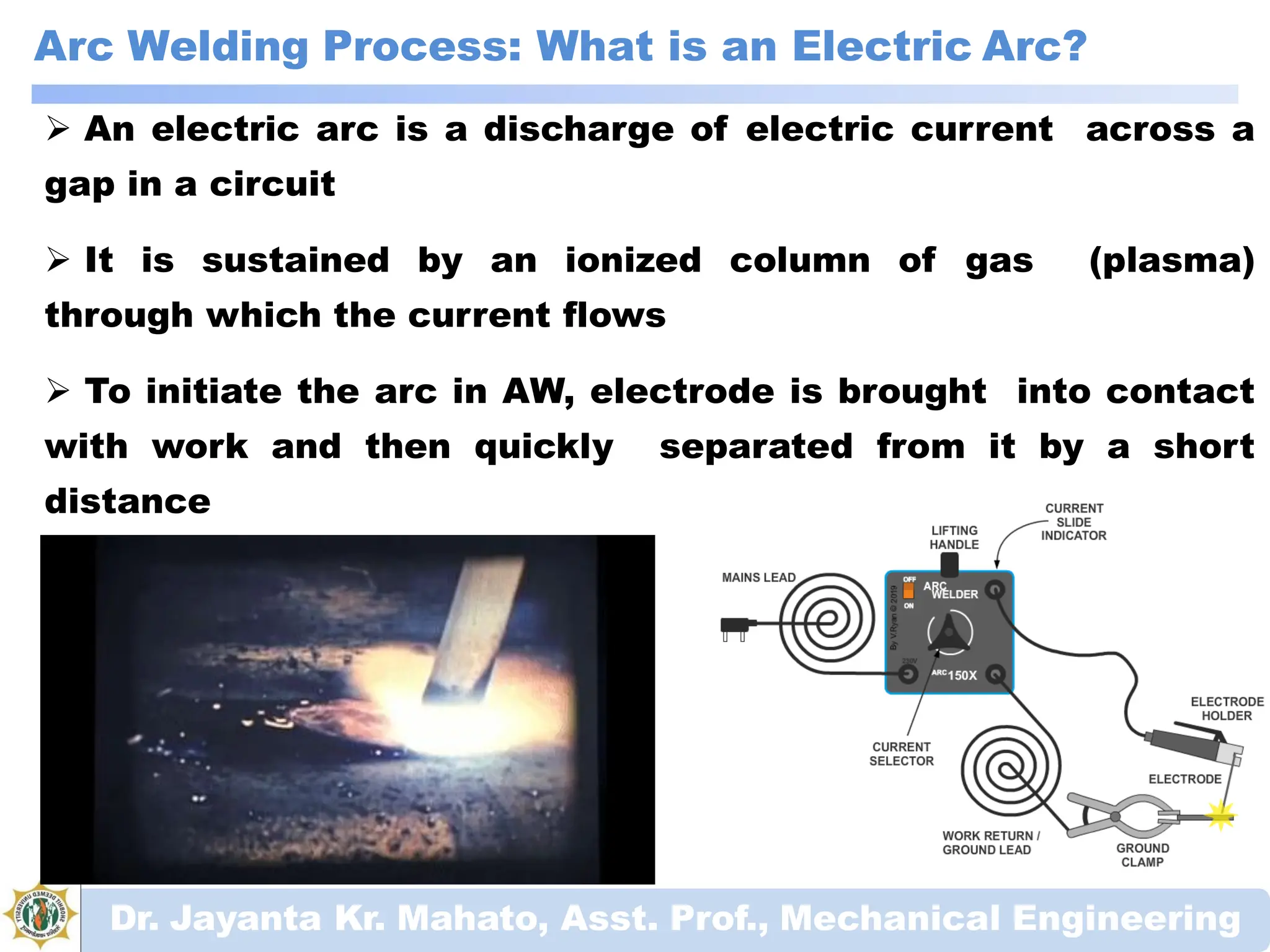

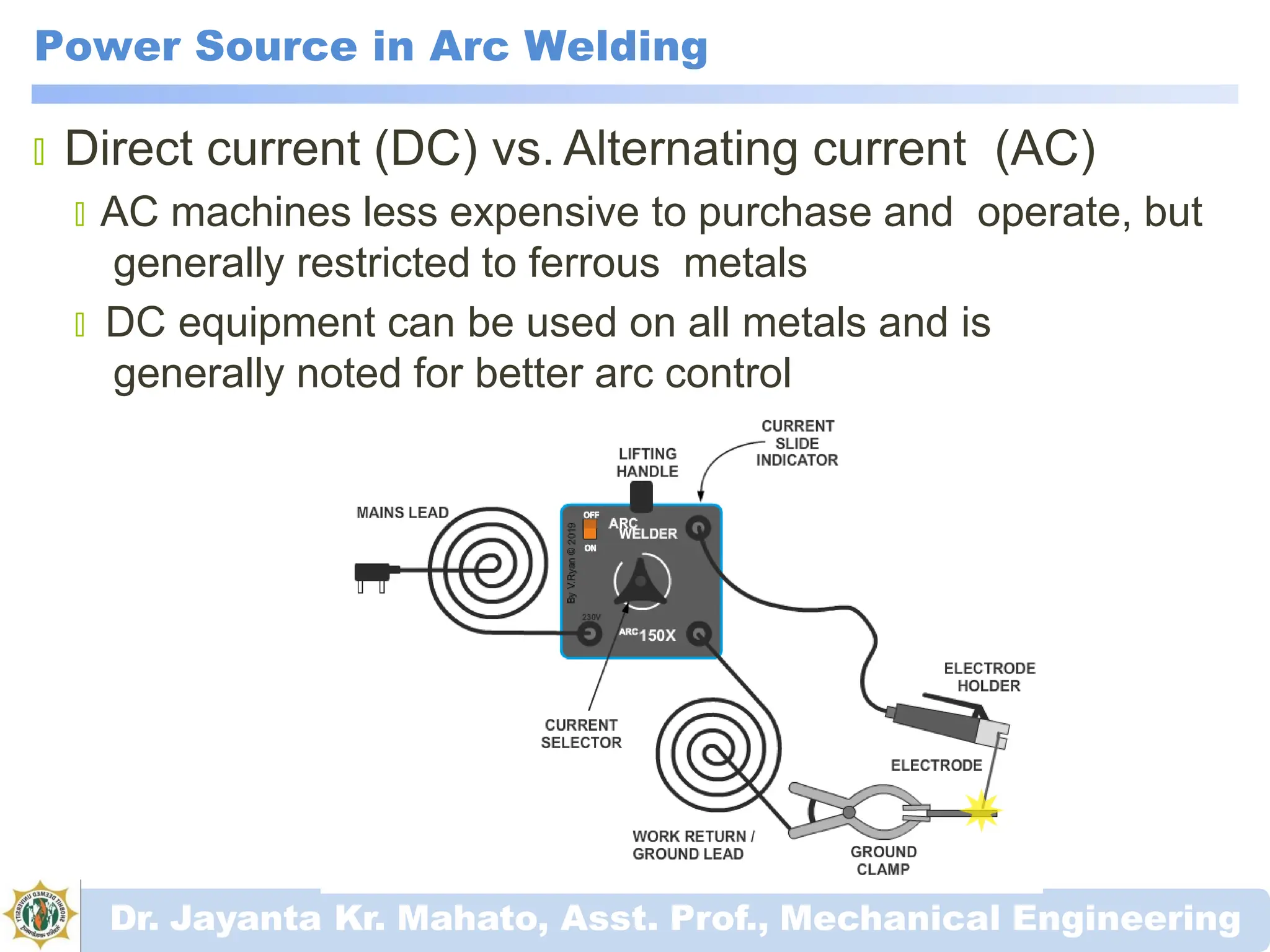

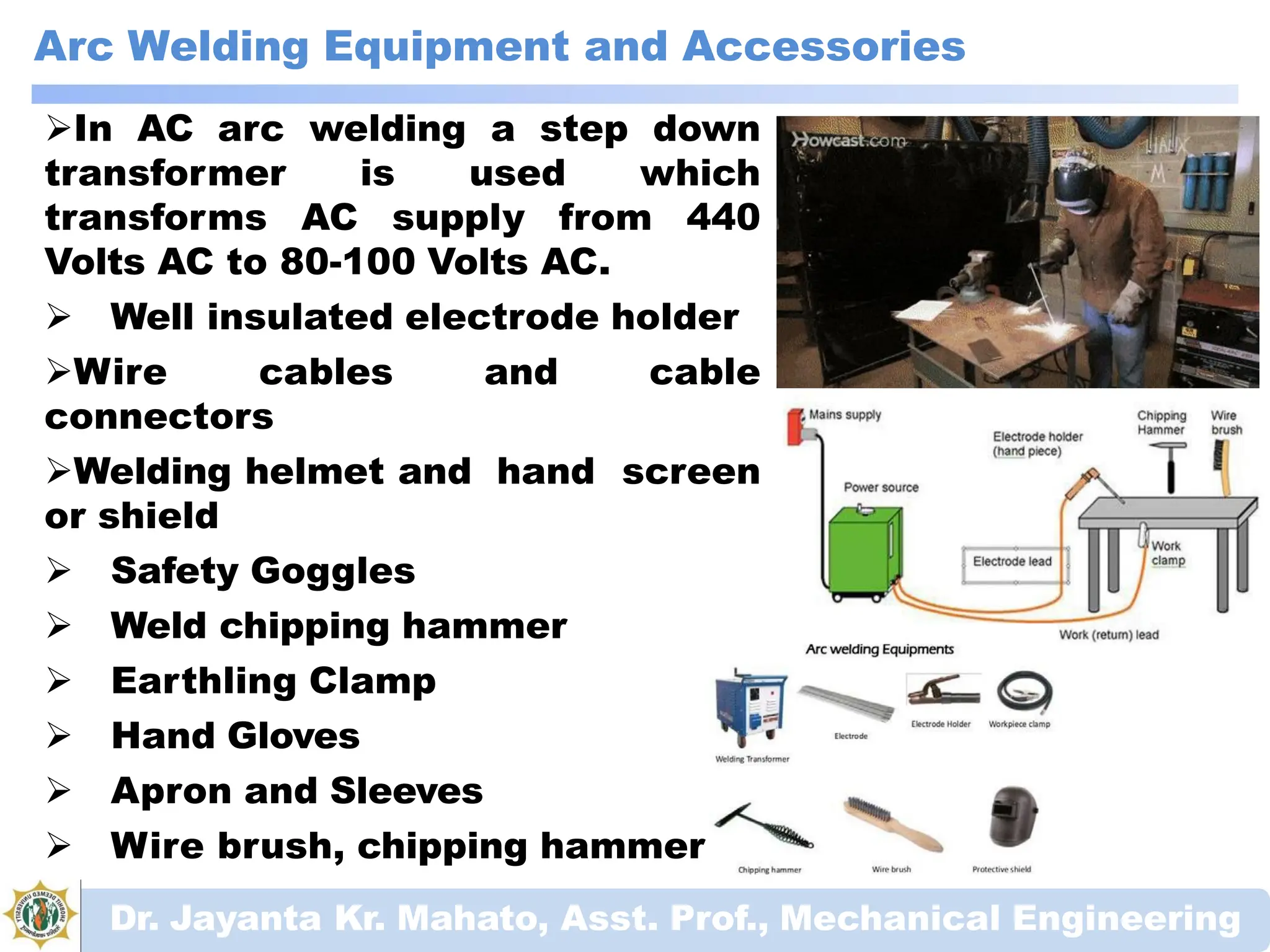

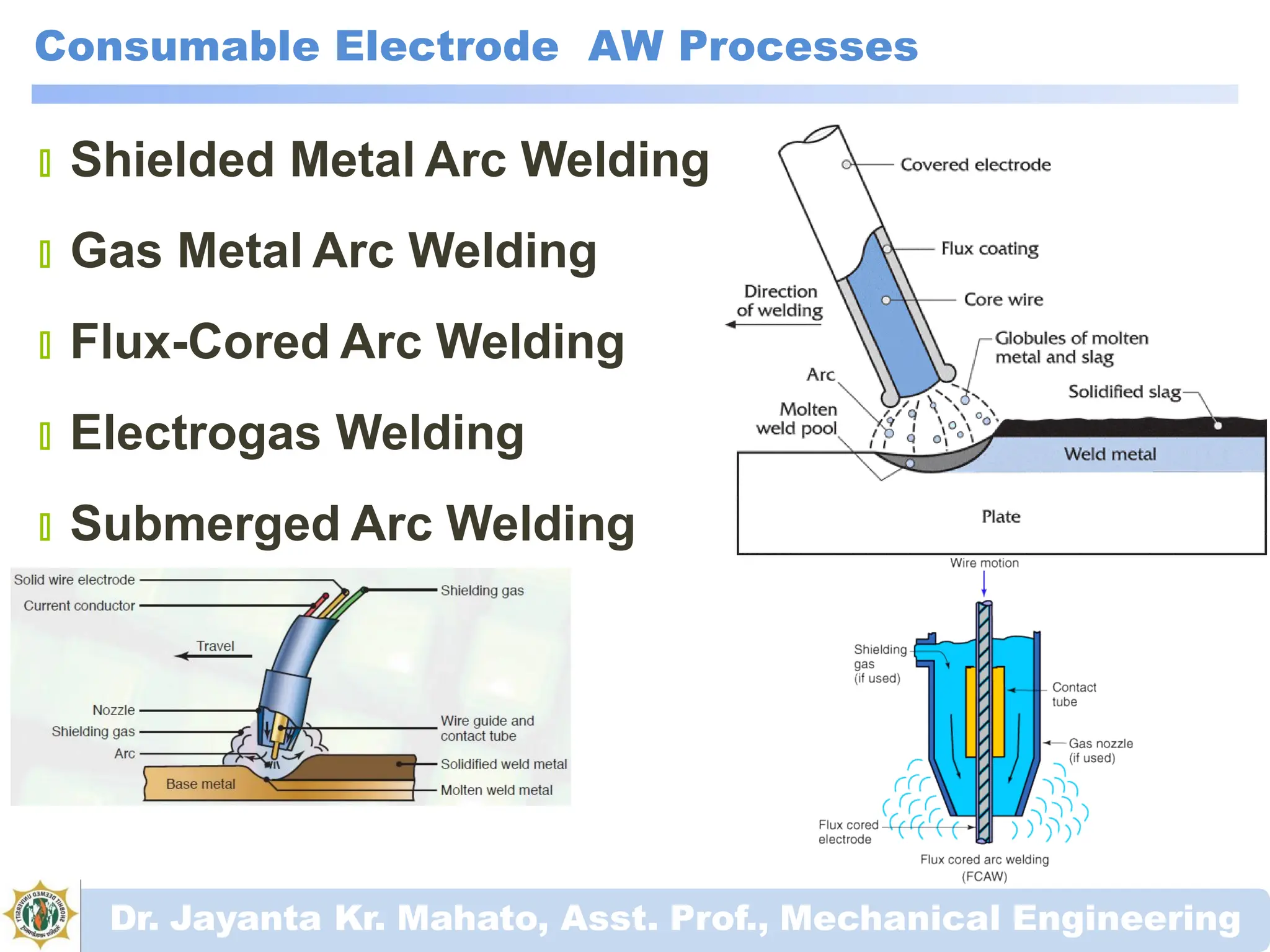

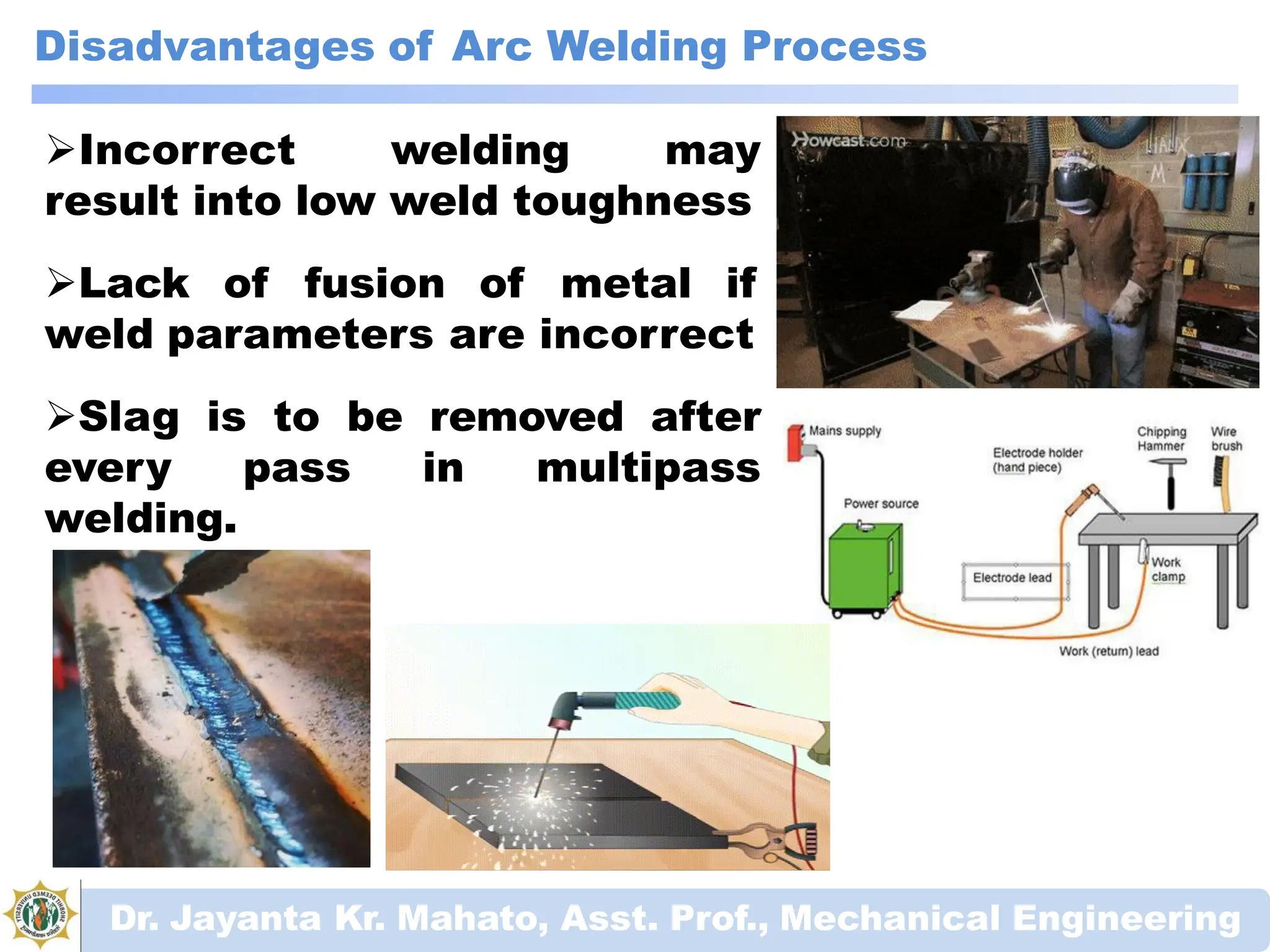

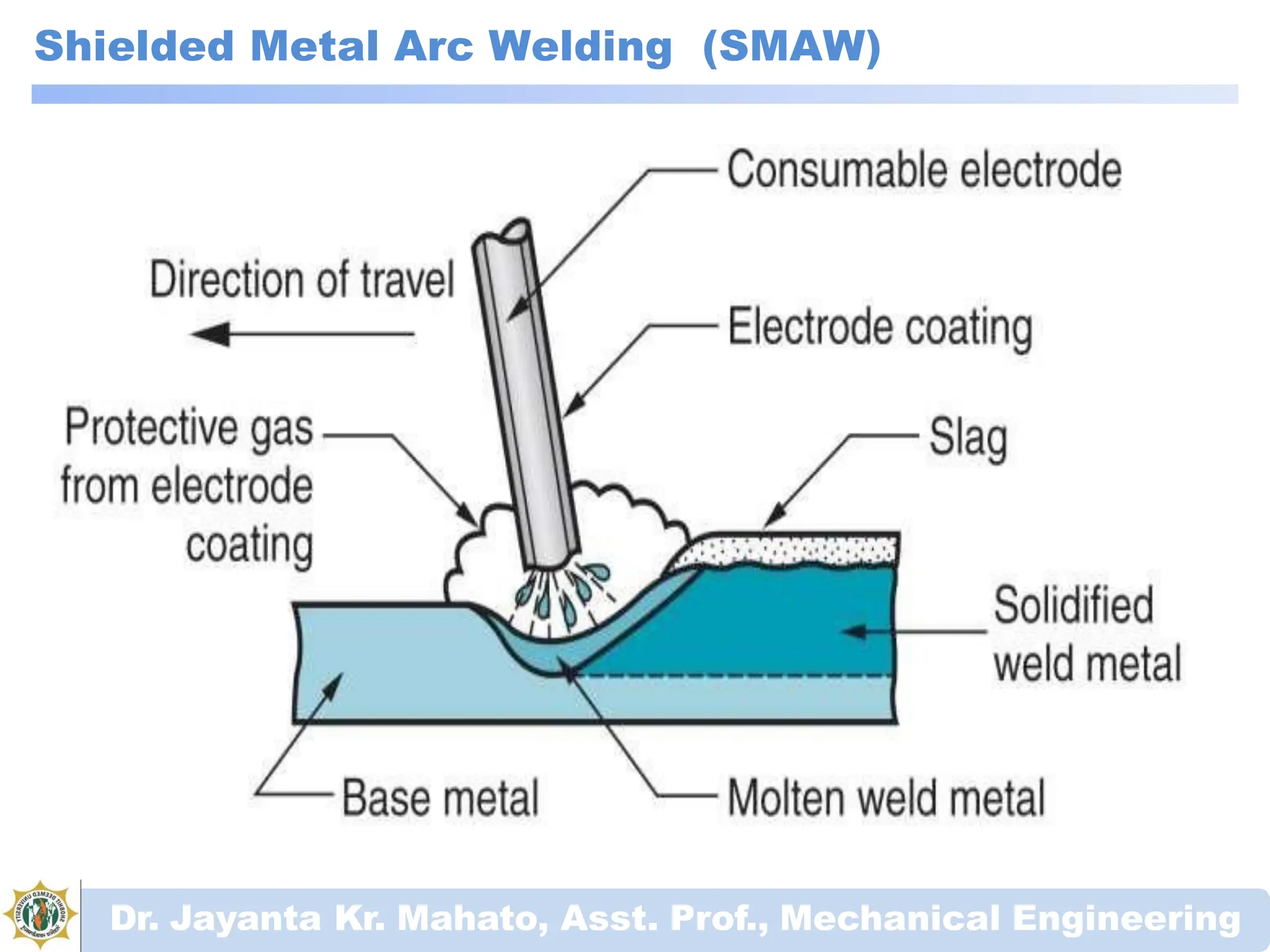

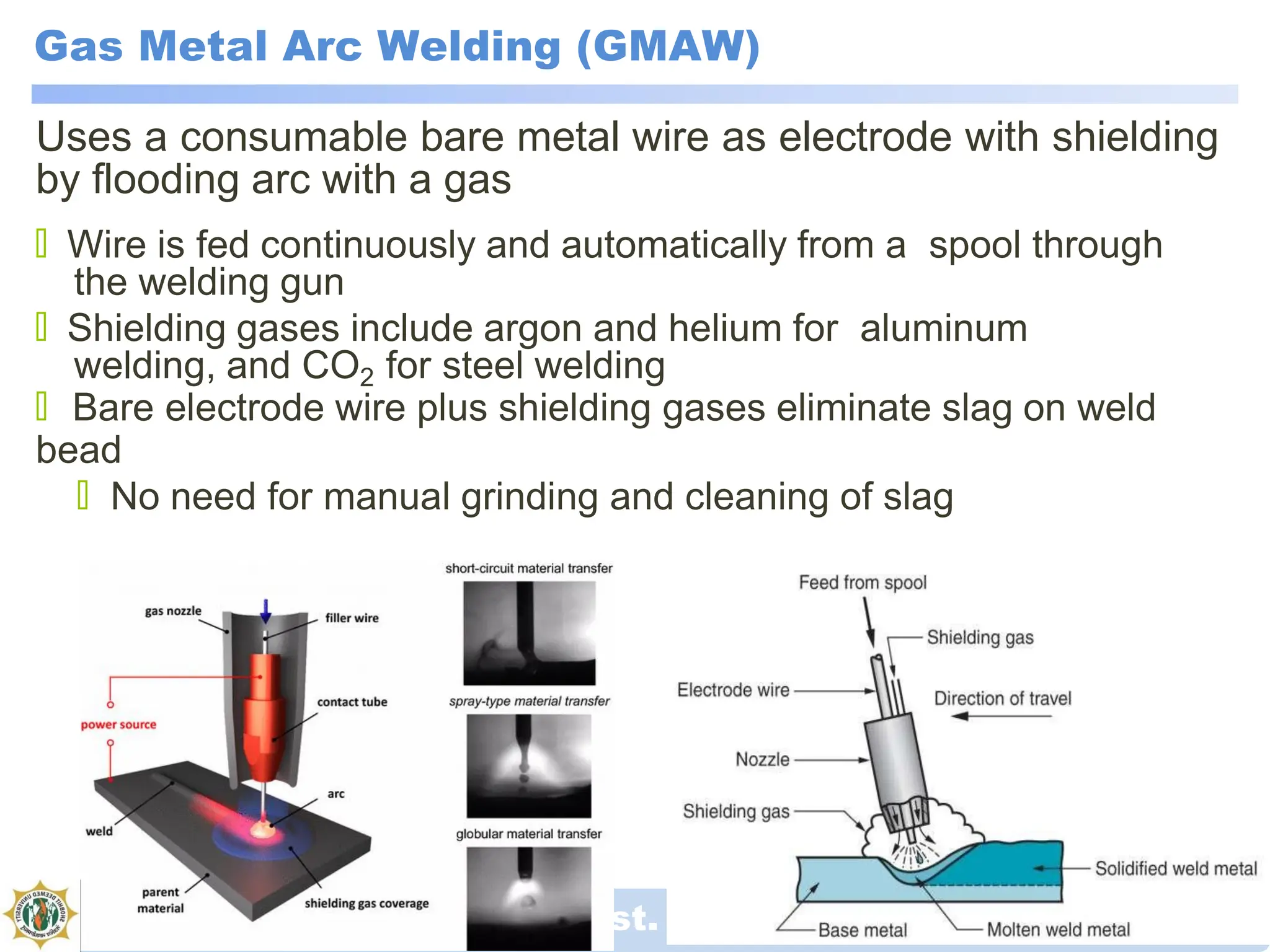

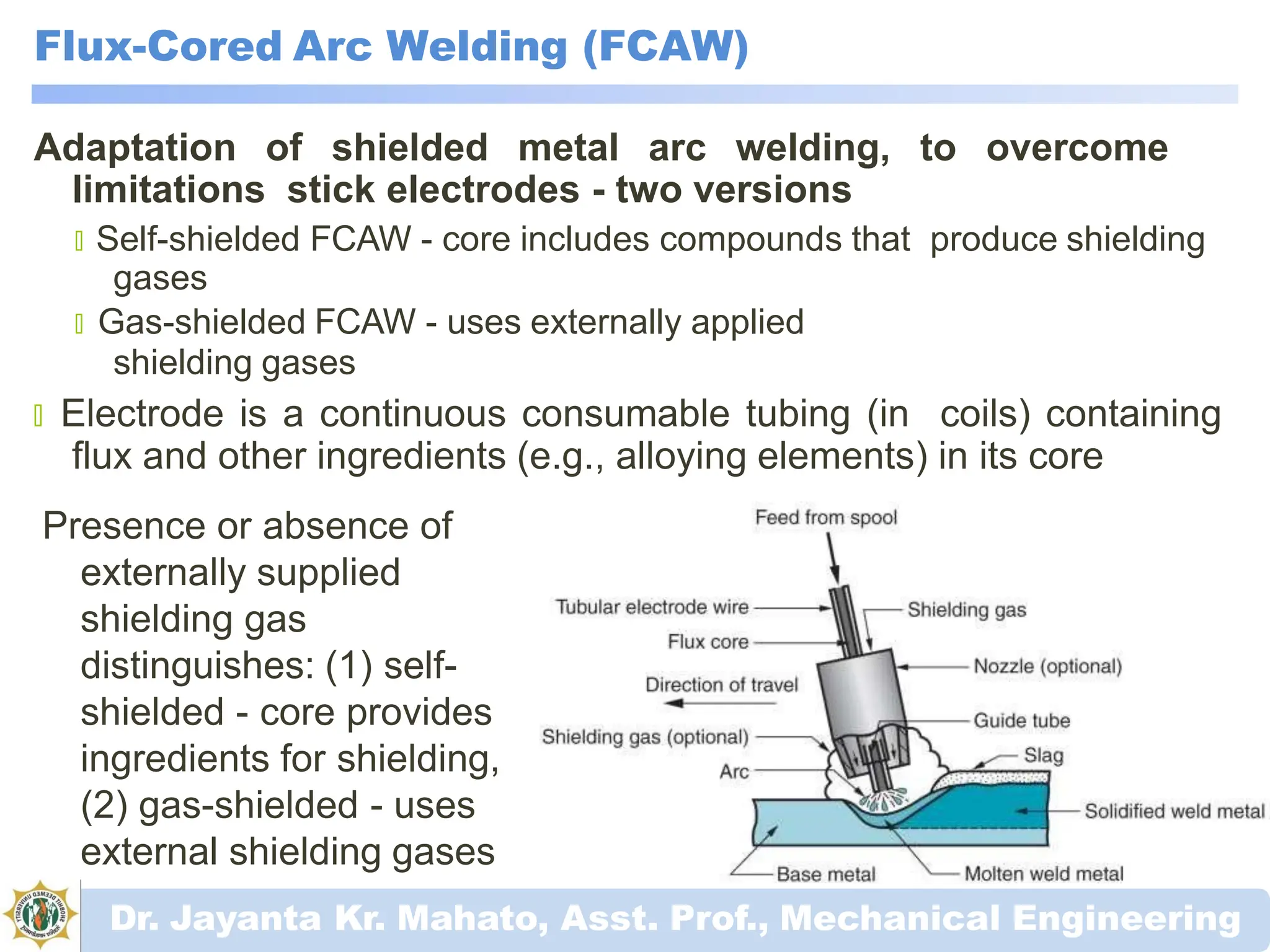

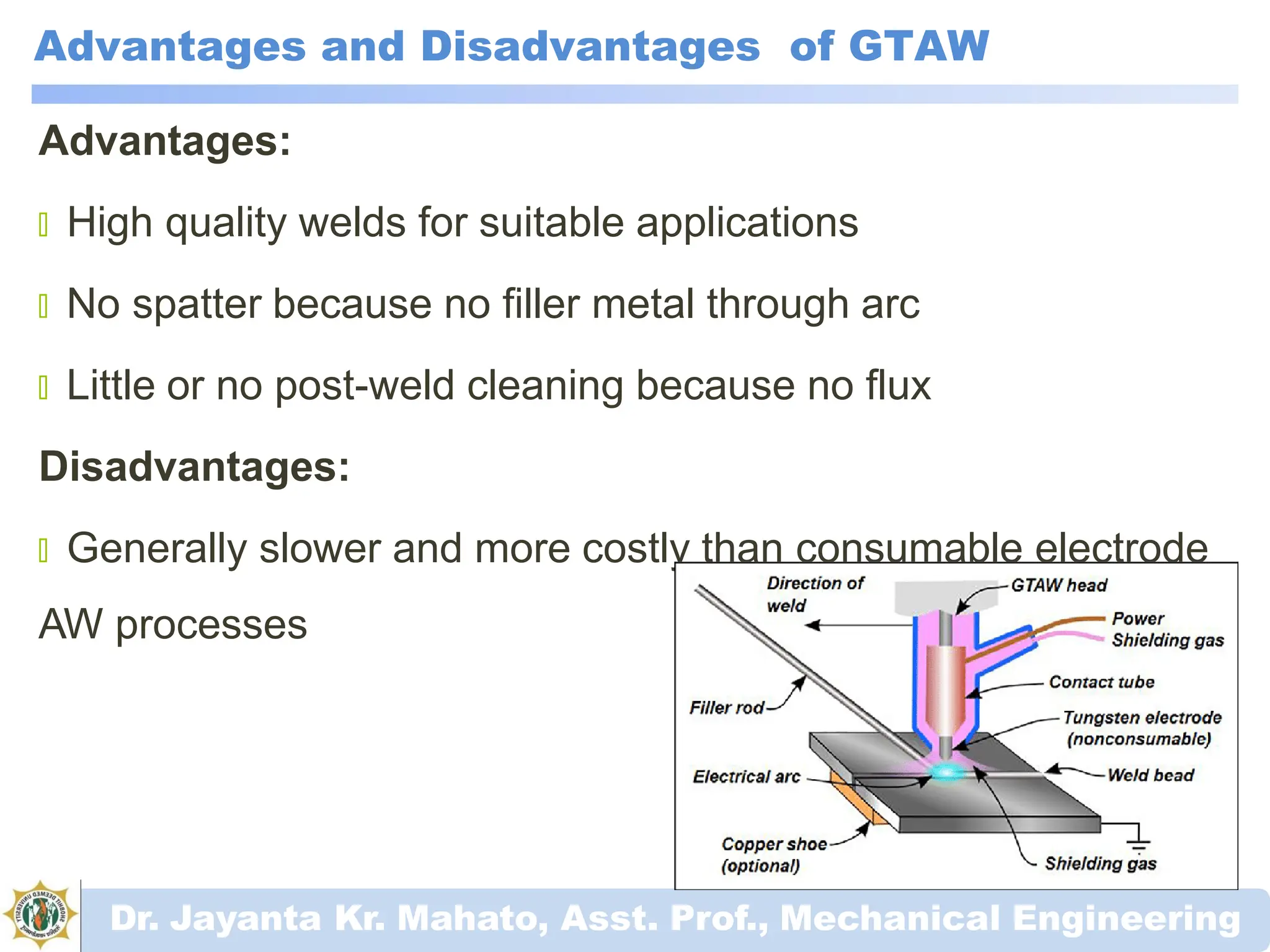

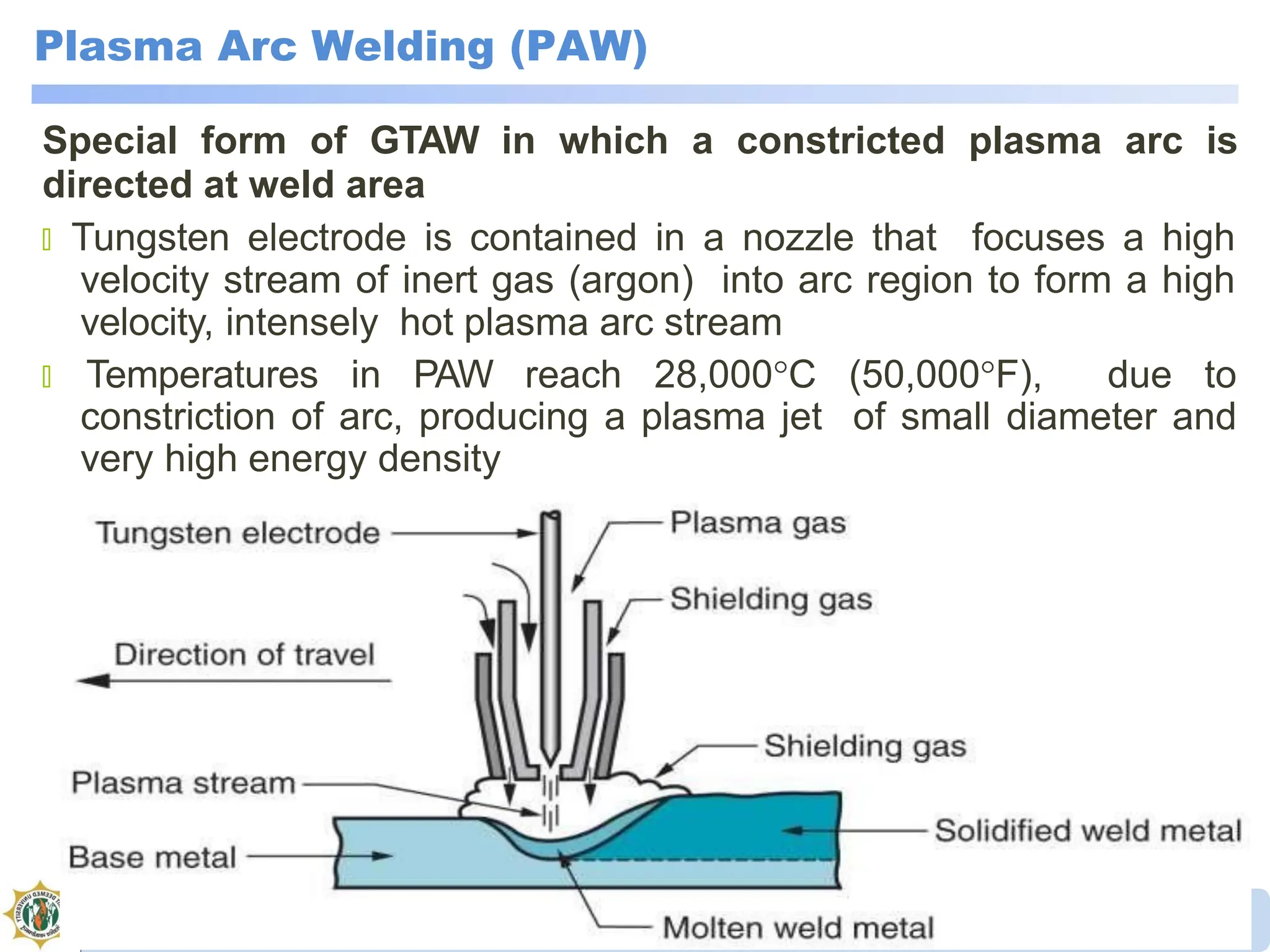

The document discusses various arc welding processes including shielded metal arc welding (SMAW), gas metal arc welding (GMAW), flux-cored arc welding (FCAW), submerged arc welding (SAW), gas tungsten arc welding (GTAW), and plasma arc welding (PAW). It provides details on the equipment, electrodes, shielding methods, applications and advantages/disadvantages of each process. The document is presented by Dr. Jayanta Kr. Mahato and focuses on explaining common arc welding techniques.