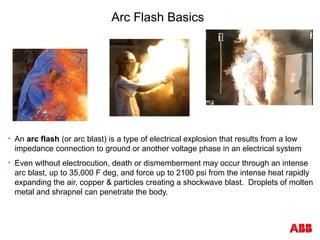

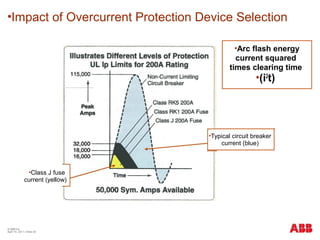

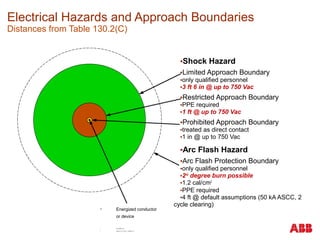

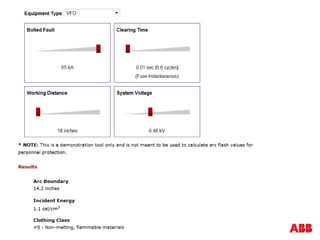

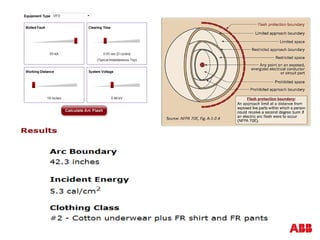

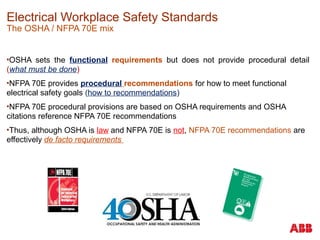

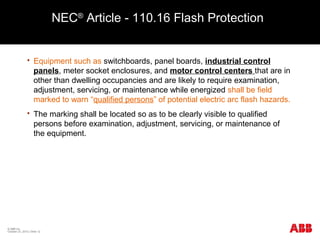

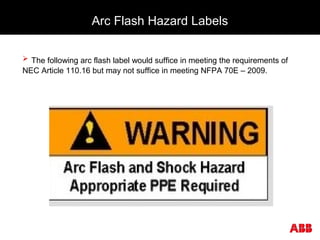

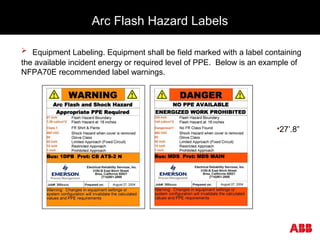

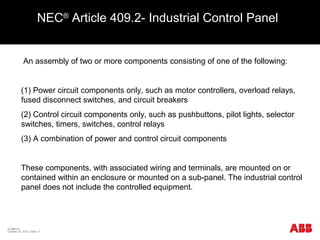

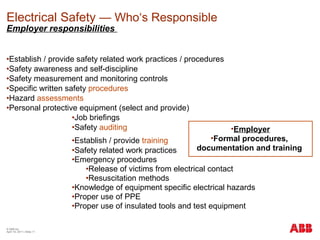

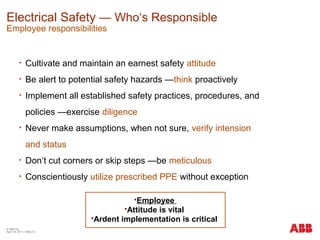

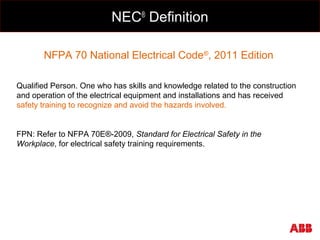

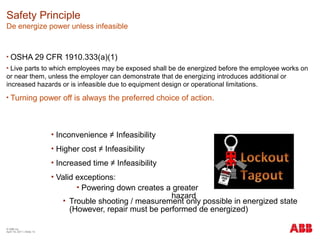

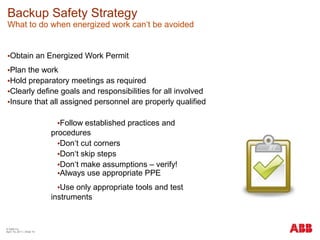

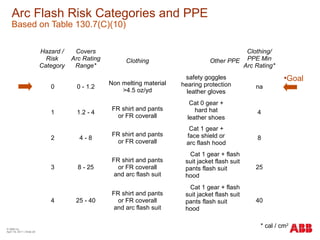

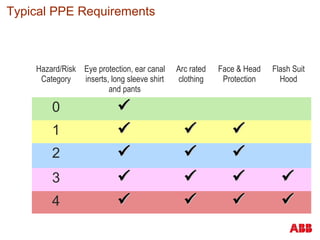

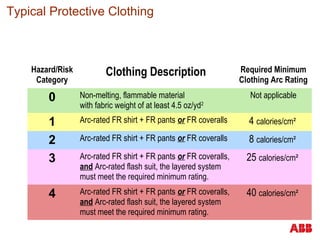

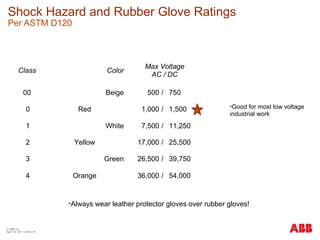

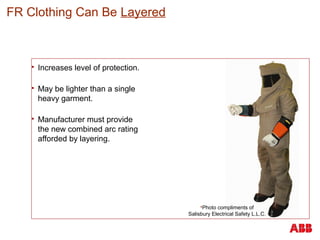

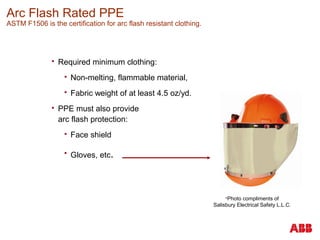

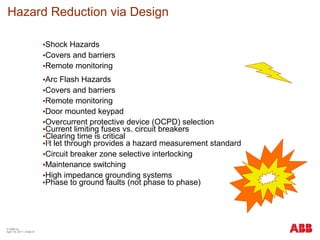

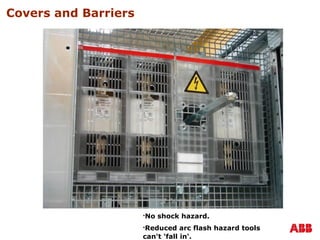

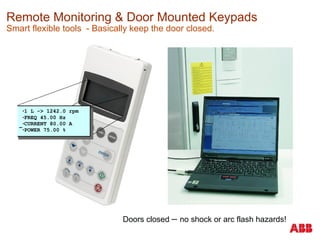

The document discusses arc flash hazards related to AC drives, outlining the basics of arc flashes, relevant OSHA and NFPA standards, personal protective equipment (PPE) recommendations, and employer and employee responsibilities for electrical safety. It emphasizes the importance of hazard assessments, safety procedures, and the use of appropriate protective clothing to mitigate risks associated with electrical work. The text also covers essential safety principles, such as maintaining an electrically safe work condition and the necessary protocols when energized work cannot be avoided.