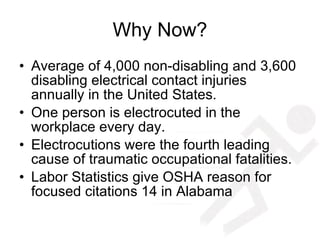

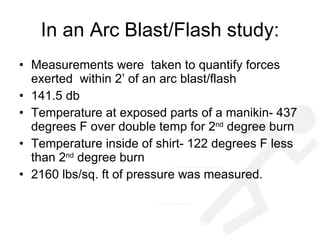

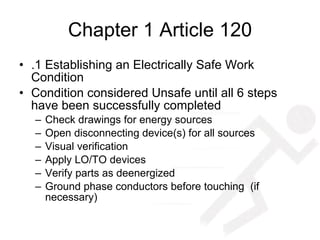

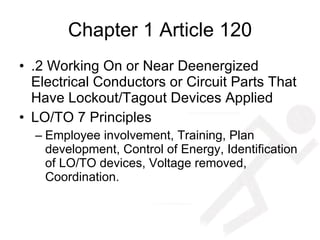

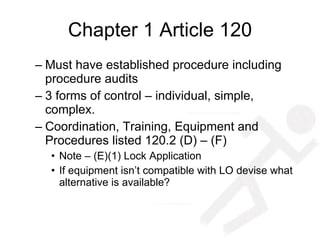

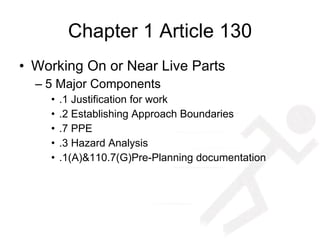

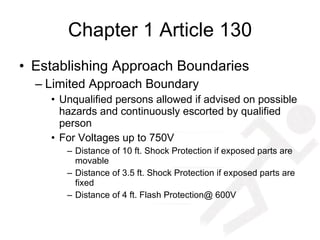

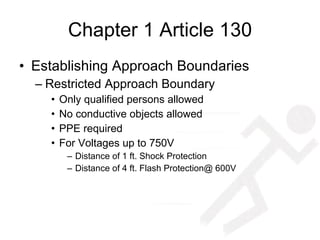

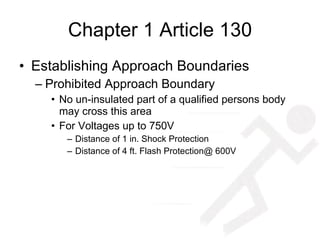

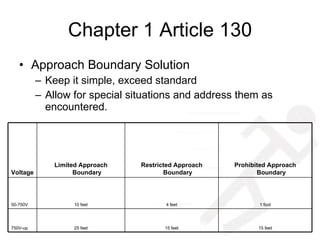

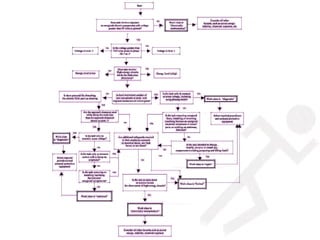

The document discusses electrical safety standards and best practices from NFPA 70E. It covers statistics on electrical injuries and fatalities to emphasize the importance of safety. NFPA 70E requirements are summarized, including establishing electrically safe work conditions, approach boundaries for live parts, protective equipment, hazard analysis, documentation and training. The presentation emphasizes creating an electrically safe work environment by de-energizing whenever possible, and having proper documentation, coordination and PPE for any justified live work.