This document provides an overview of electrical safety topics including:

- The four main types of electrical injuries and their hazards

- Requirements for personal protective equipment, safe work practices, and lockout/tagout procedures when working with electrical equipment

- Hazards of arc flash and the importance of de-energizing circuits before conducting work

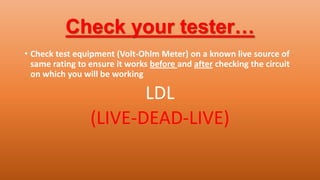

- Proper inspection and ratings for test instruments, tools, and other equipment used for electrical work