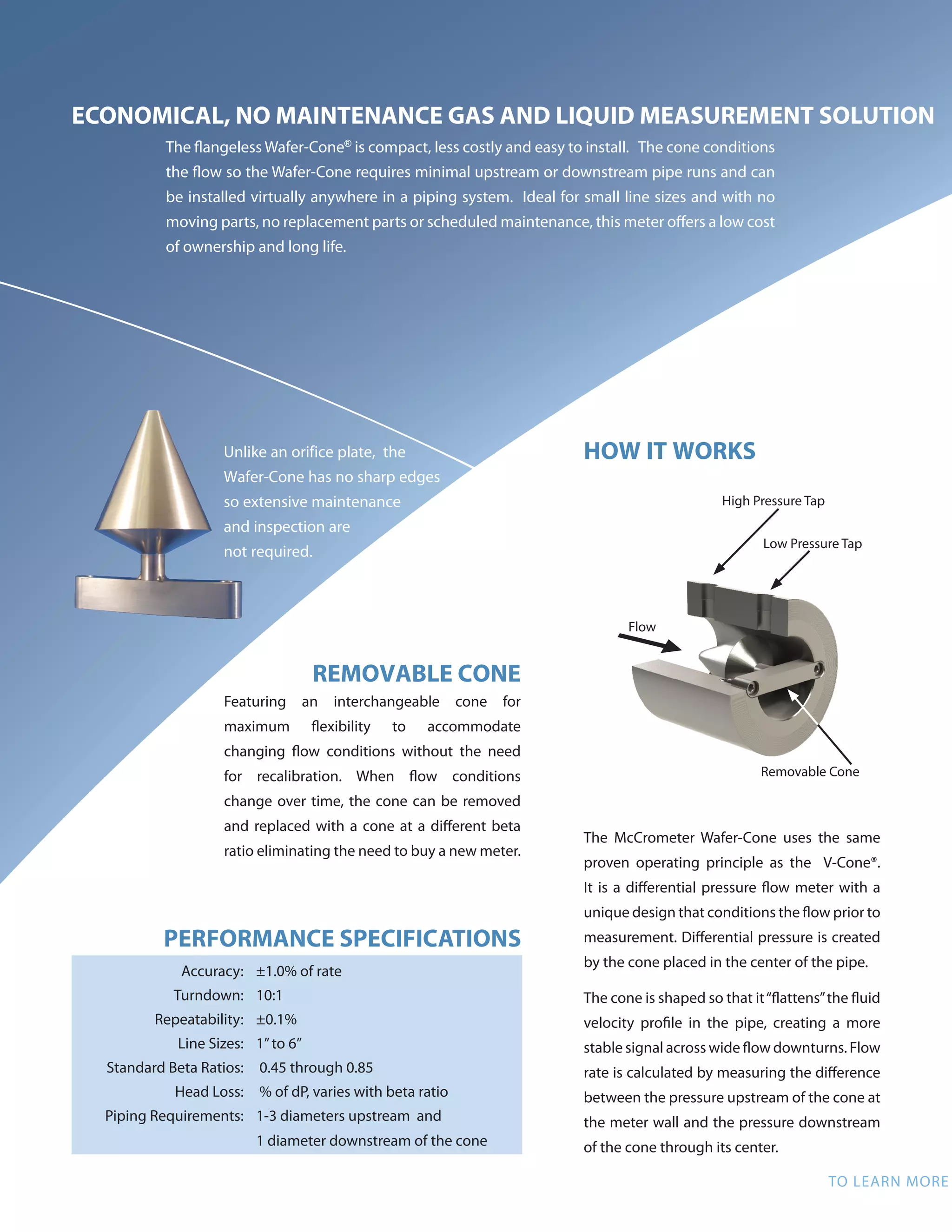

The document outlines the features and benefits of the McCrometer Wafer-Cone® flow meter, highlighting its compact design, easy installation, and low maintenance requirements. It operates on a differential pressure principle, effectively conditioning fluid flow for greater accuracy, making it suitable for various industries such as oil and gas, food, and pharmaceuticals. Additionally, it emphasizes the company's commitment to high-quality calibration processes and the durability of their flow measurement solutions.