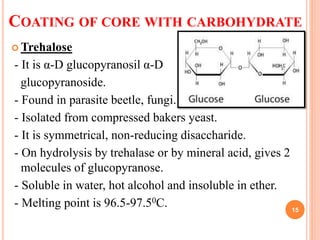

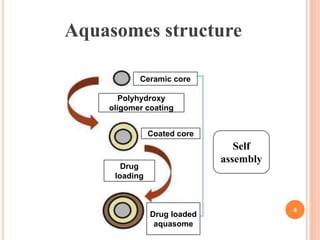

The document discusses aquasomes, which are self-assembled three-layered nanostructures that protect and preserve fragile biological molecules. It details their preparation process, which includes creating a ceramic core, coating it with carbohydrates, and immobilizing drugs. Applications of aquasomes include delivering vaccines, insulin, and as a red blood cell substitute, demonstrating their potential in drug delivery systems.

![COATING OF CORE WITH CARBOHYDRATE

Pyridoxal-5-phosphate

- Prepared by action of phosphorous

oxychloride on pyridoxal in

aqueous solution and by phosphorylation of

pyridoxamine with

100% H3PO4 followed by oxidation.

- It is colourless in acid solution and bright yellow in

alkaline solution.

- On oxidation with Hydrogen peroxide in alkaline

solution gives [(2-methyl-3,4-dihydroxy-5-

pyridyl)methyl] phosphoric acid.

- It gives negative 2,6-dichloroquinone chlorimide test.

14](https://image.slidesharecdn.com/aquasomes-200702103213/85/Aquasomes-14-320.jpg)