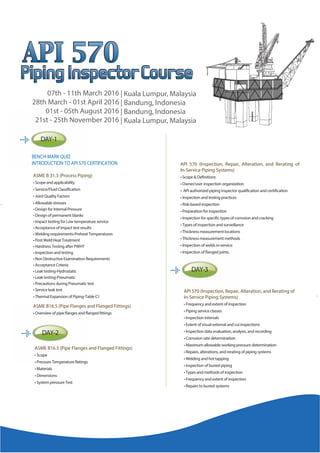

This document provides information on an upcoming API 570 Piping Inspector certification course, including details on the instructor, dates and locations of the course, an overview of topics that will be covered, the target audience, and benefits of attending. The instructor, Uday B. Kale, has over 18 years of experience in inspection, welding and non-destructive testing. The 5-day course will cover API and ASME codes and recommended practices relevant to inspecting in-service piping systems, including API 570 and 574, ASME B31.3, and conducting mock certification exams. The course is intended to benefit engineering and technical professionals working in oil, gas, and petrochemical facilities.