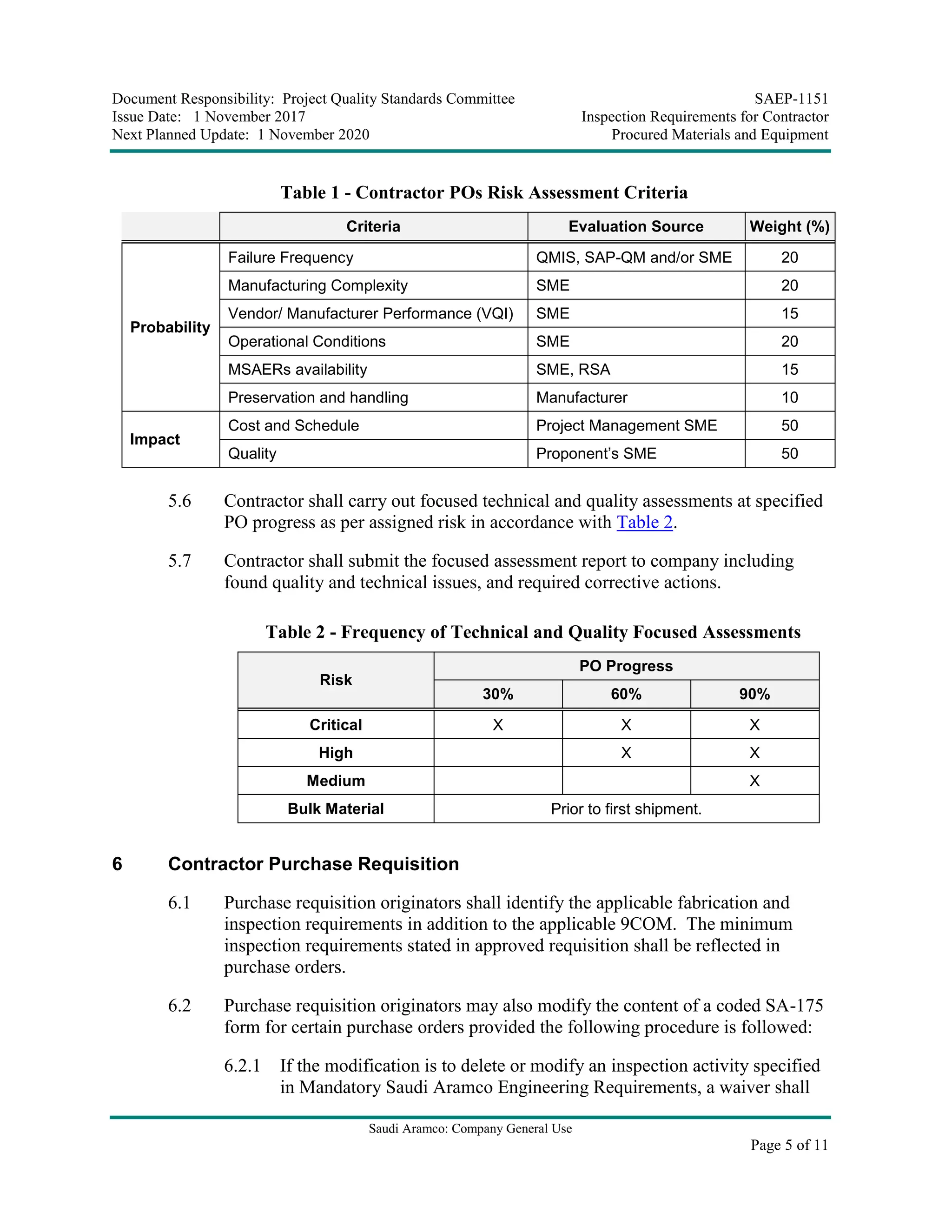

This document outlines inspection requirements for materials and equipment procured by contractors for Saudi Aramco projects. It defines procurement risk management procedures, including developing a risk register and conducting focused assessments. It also specifies requirements for contractor purchase requisitions and inspection and test plans, including identifying applicable Saudi Aramco inspection forms and modifying forms if needed. The goal is to ensure quality and minimize rework for critical and high-risk procurement items.