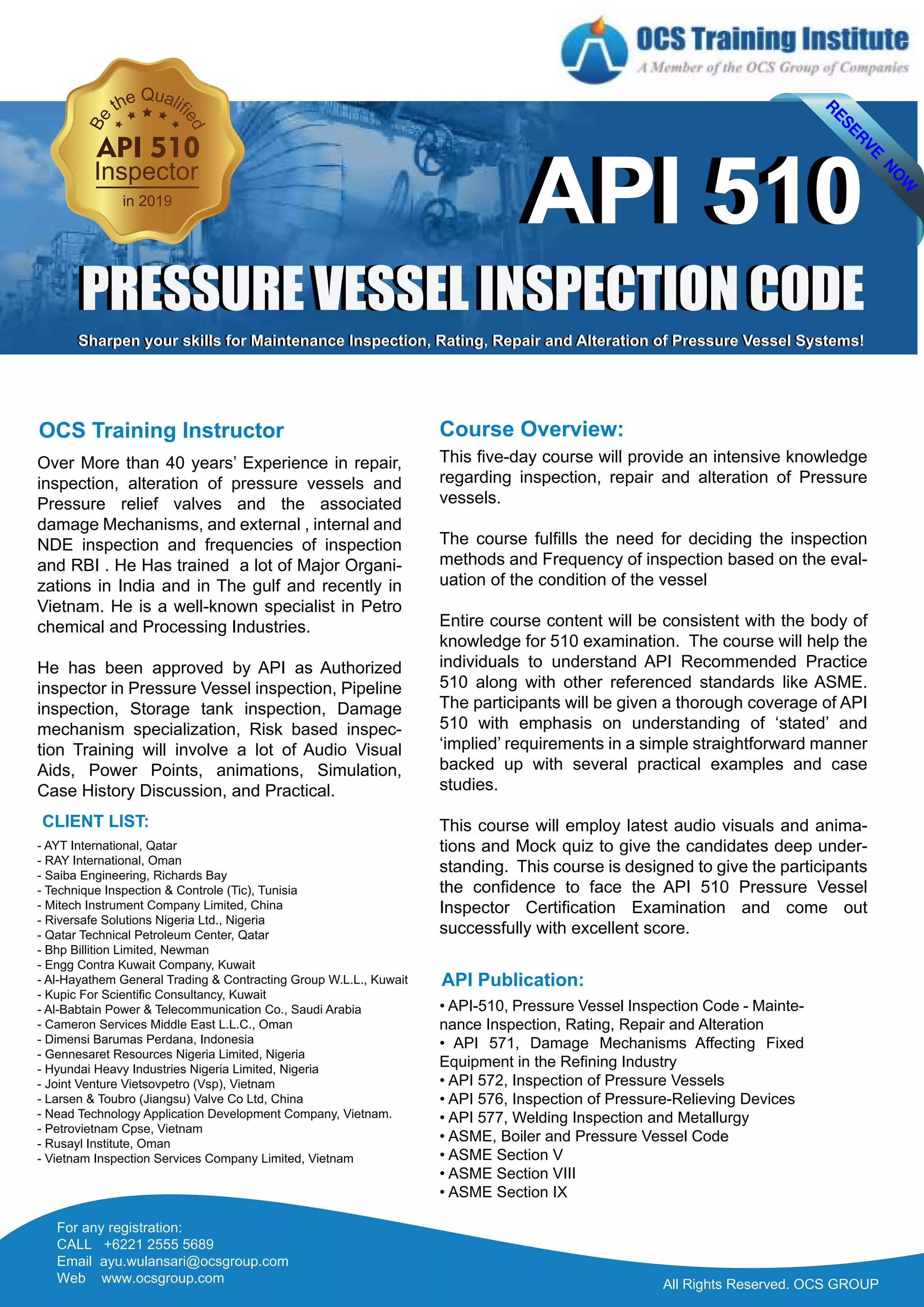

The document outlines a comprehensive training program on API 510 pressure vessel inspection, detailing the course's objectives, modules, and client list across various countries. It focuses on equipping participants with essential knowledge in inspection, maintenance, and alteration of pressure vessels, ensuring they are well-prepared for the API 510 certification exam. The training employs interactive methods, including audiovisual aids and practical case studies to reinforce learning.