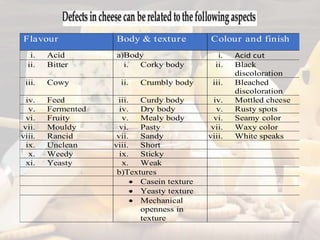

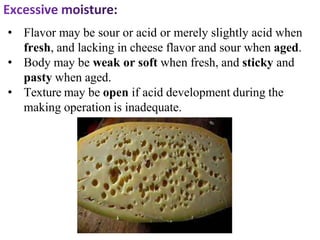

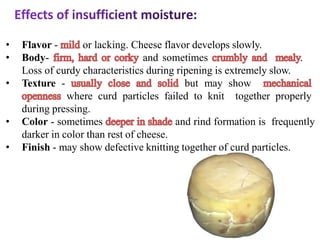

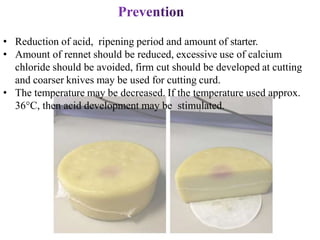

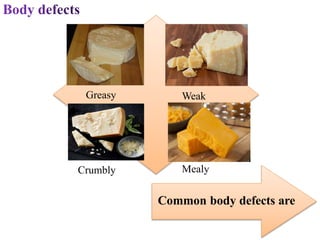

This document discusses various defects that can occur in cheese, including flavors, body, texture, color, and finish defects. It outlines the potential causes of different defects such as high acidity, moisture content, improper manufacturing processes, and contamination. Maintaining quality control at each stage of production from milk sourcing to ripening is important to prevent defects and ensure consistent cheese quality. Identifying defects early through quality control testing allows issues to be addressed before widespread impacts.