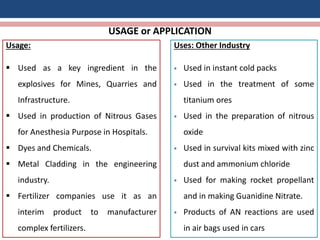

The Home Ministry has asked for a ban on ammonium nitrate production in India due to safety risks. This would negatively impact ammonium nitrate producers. Stakeholders need to consider how important ammonium nitrate is for the country's economy and find ways to mitigate risks to producers. Ammonium nitrate is a key ingredient in explosives and is widely used in mining and infrastructure development, which are important industries for India's growth.