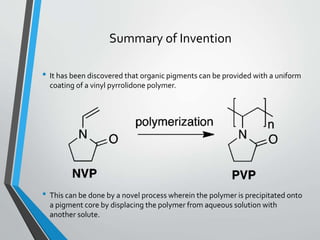

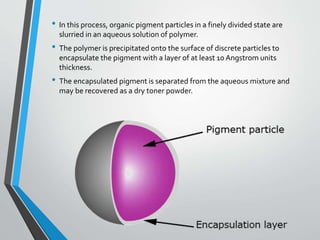

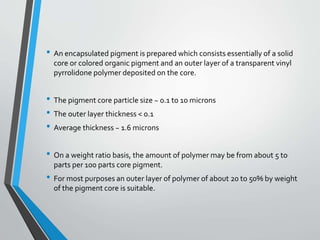

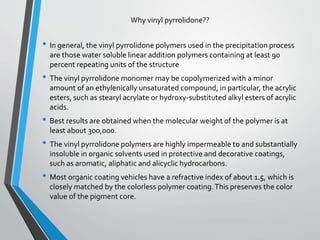

- Organic pigments can be encapsulated with a vinyl pyrrolidone polymer coating via a process where the polymer is precipitated onto pigment particles from an aqueous solution. This process results in a uniform 10 Angstrom thick polymer coating on the pigment particles.

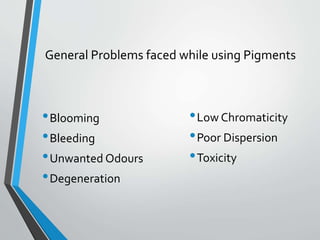

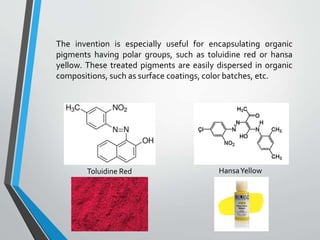

- Encapsulating organic pigments like toluidine red with vinyl pyrrolidone polymer improves their dispersion in organic compositions and prevents issues like blooming, bleeding, and dissolution in solvents.

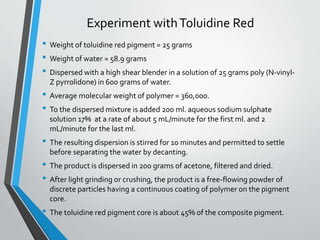

- In an experiment, toluidine red pigment particles were encapsulated with poly(N-vinyl-2-pyrrolidone) polymer via this process. The encapsulated pigment particles remained insoluble after

![CASE STUDY

Organic pigments encapsulated with

VinylPyrrolidone Polymer

n-Vinylpyrrolidone

11] 3,904,562 ORGANIC PIGMENTS ENCAPSULATEDWITHVINYLPYRROLIDONE POLYMER

[75] Inventors: Harold B. Hopfenberg, Raleigh,NC;Thomas C. Rees, Park Forest South, 111.[73]

Assignee:TheSherwin-Williams Company,Cleveland, Ohio [22] Filed: [21]App]. No.: 328,201](https://image.slidesharecdn.com/paintsandpigments-160124094400/85/Paints-and-pigments-21-320.jpg)