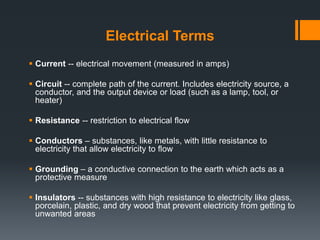

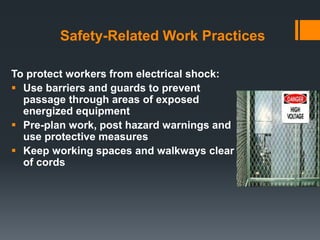

The document provides critical electrical safety guidelines, emphasizing the importance of using properly labeled equipment, safety practices, and protective measures to prevent electrical hazards. It outlines essential electrical terms, tool safety tips, and work practices to protect workers from electrical shocks. Additionally, it stresses the need for ongoing training and awareness to ensure safe handling of electrical tools and equipment.