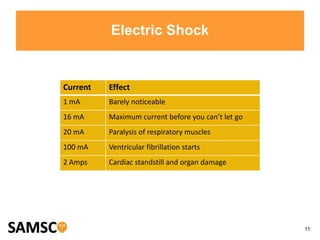

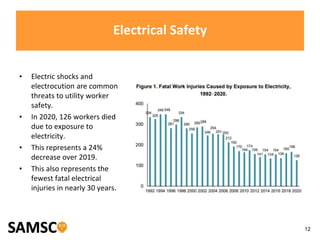

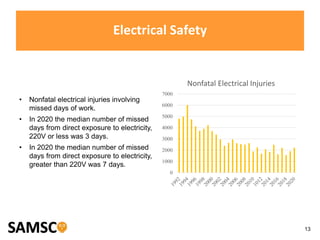

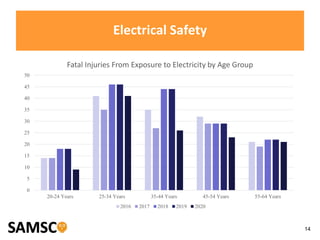

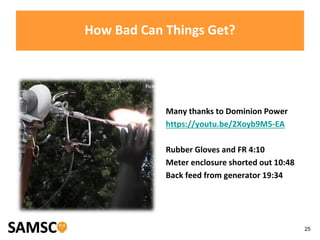

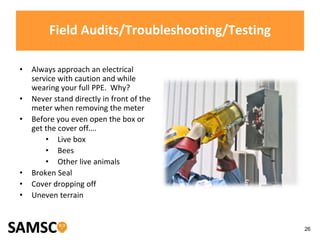

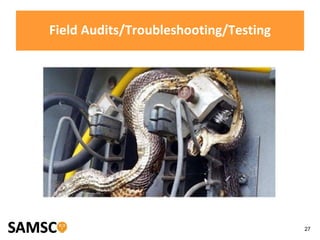

This document discusses electrical safety hazards and proper personal protective equipment for utility workers. It outlines several common hazards like falls, chemical exposure, fires, and electrical hazards. Electrical shock can cause minor to serious injuries depending on the current and contact location. Proper personal protective equipment like leather gloves, face shields, and flame-resistant clothing are reviewed. Common safety issues seen in the field like open lines, missing neutrals, and cross phases are also discussed. The presentation emphasizes treating electricity with respect and assuming all meter boxes are live for safety.